2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

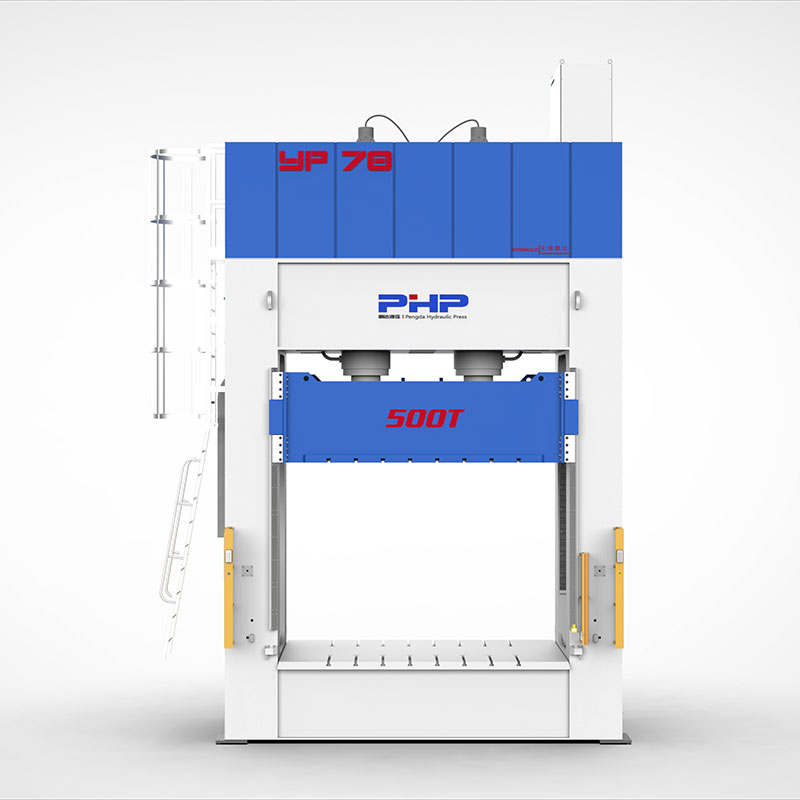

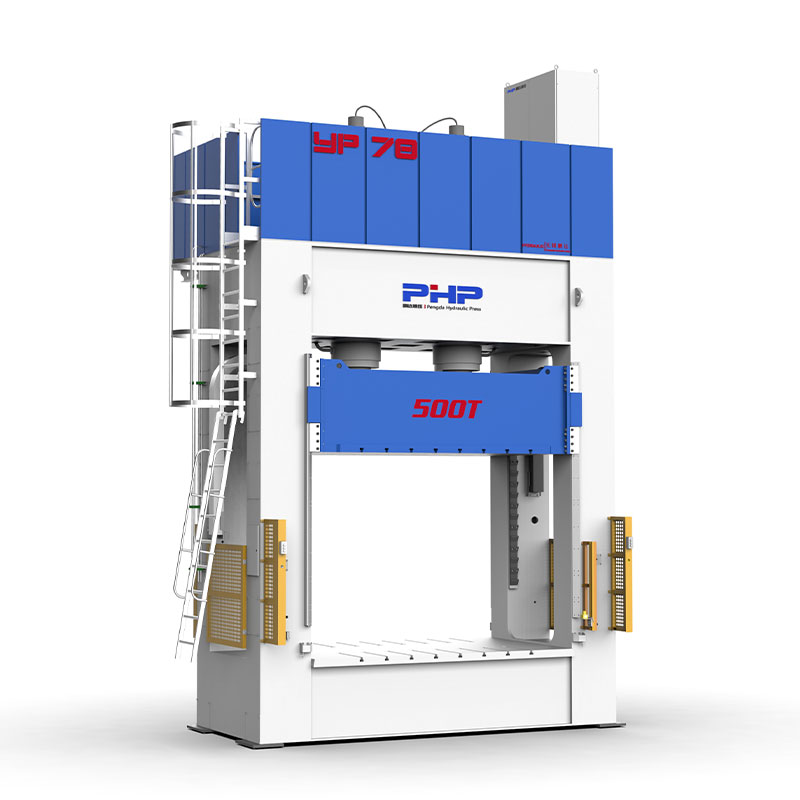

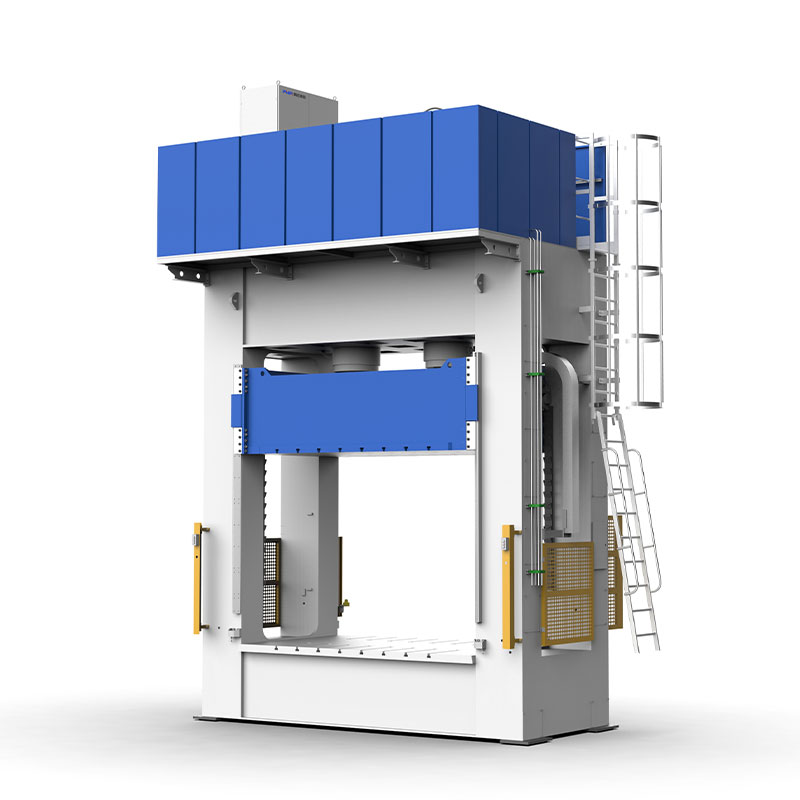

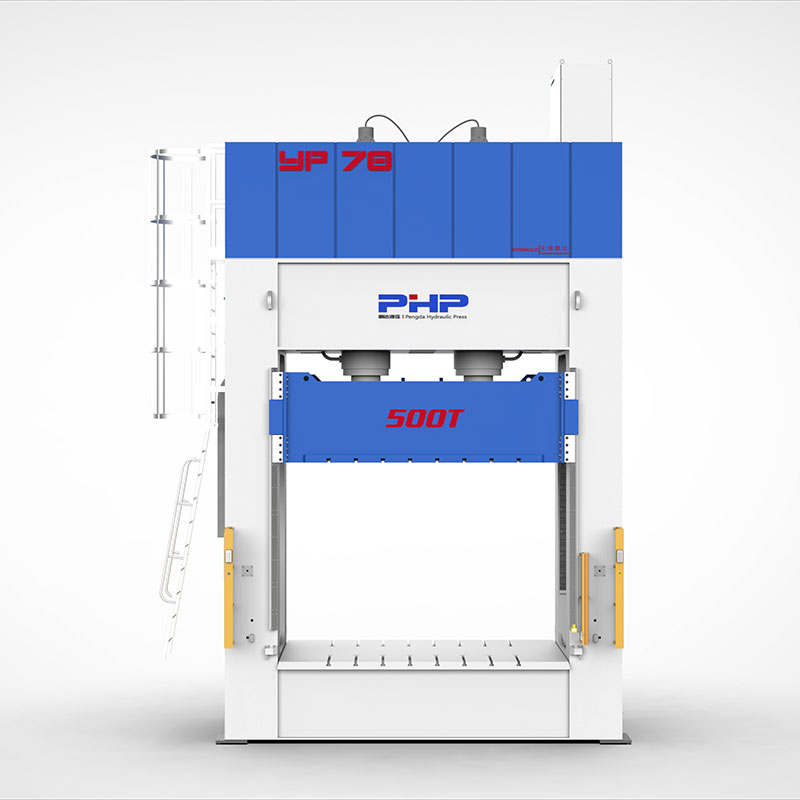

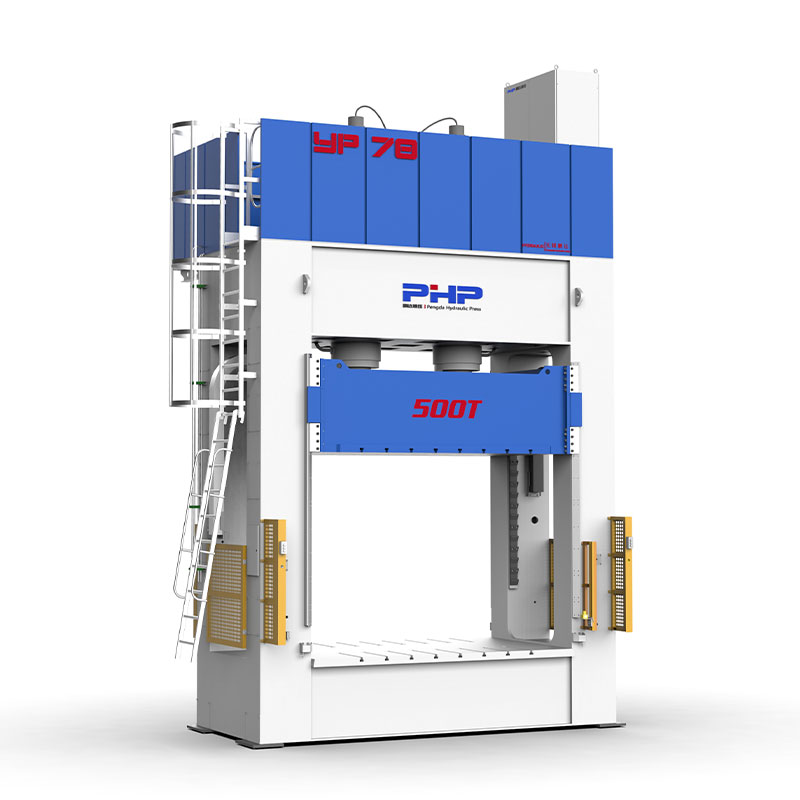

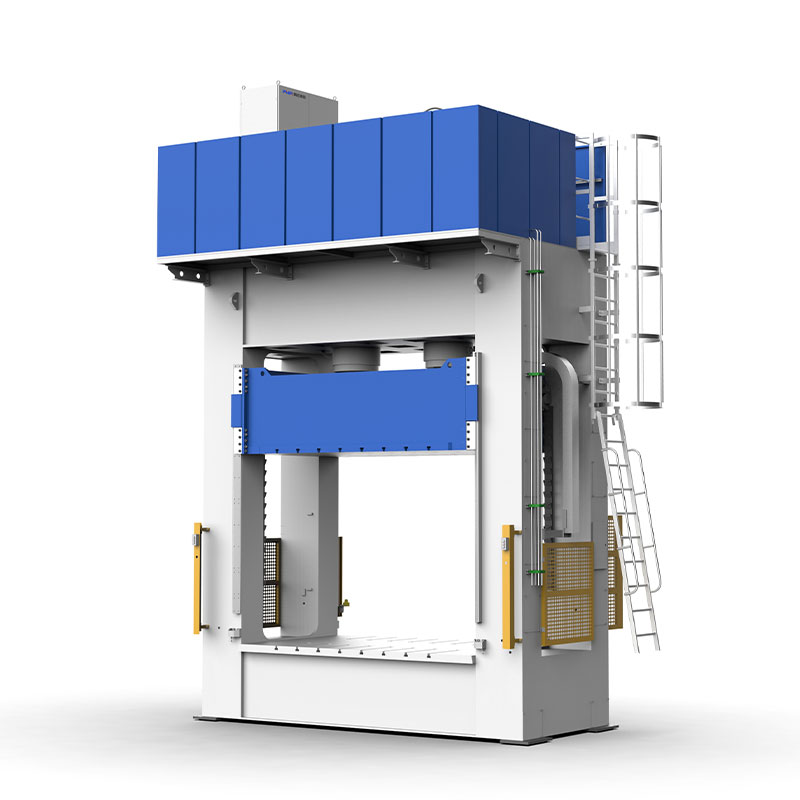

The STM (Sheet Transfer Molding) press is a specialized hydraulic machine designed for the STM process, where pre-impregnated fiberglass mats or fabrics are transferred into a heated mold for compression molding. In this process, thermoset resin is sprayed or coated onto the glass fiber reinforcement to form a pre-shaped sheet, which is then placed into the mold and cured under high temperature and pressure. STM presses offer short cycle times, excellent material efficiency, and high part quality. They are widely used in automotive interior and structural components, as well as lightweight enclosures in the electrical and industrial sectors.

STM Servo Composite Hydraulic Press

STM Polyurethane Battery Pack Solution

The STM process adopts advanced spray transfer molding technology, and the PU formula resin is accurately sprayed onto the glass fiber felt by a robotic arm. Then transfer these glass fiber mats into a mold, press them in the mold to form composite components, and cure them at a certain temperature.

|

|

|

| Battery Cover Tray | Battery Cover |

| Type | Unit | 500T | 800T | 1000T | 1500T | |

| Max. fluid pressure | MPa | 25 | 25 | 25 | 25 | |

| Max. Opening | mm | 2200 | 2200 | 2400 | 2500 | |

| Max. Stroke | Mm | 1800 | 1800 | 1800 | 2000 | |

| Working table size | L-R | mm | 3200 | 3200 | 3500 | 3500 |

| F-B | Mm | 2000 | 2000 | 2000 | 2500 | |

| Speed | Fast down | mm | 300 | 300 | 300 | 500 |

| Pressing | mm | 5~15 | 5~15 | 5~15 | 5~20 | |

| Slow return | mm | 30~50 | 30~50 | 30~50 | 30~50 | |

| Fast return | mm | 150 | 150 | 200 | 200 | |

| Power | mm | 37 | 56 | 67 | 81 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom STM Servo Molding Press Manufacturers and STM Servo Molding Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

In recent years, the manufacturing sector has increasingly emphasized efficiency, precision, and sustainability, particularly in the field of non-metallic molding. Among the technologies leading this transformation is the STM servo molding press, a sophisticated solution combining hydraulic precision with advanced servo-driven systems. These presses are integral in meeting the high demands of industries ranging from new energy vehicles to aerospace, urban construction, and specialized military applications. Understanding the unique capabilities, applications, and operational advantages of STM servo molding presses is crucial for manufacturers seeking both innovation and operational excellence.

The STM servo molding press represents a convergence of traditional hydraulic press mechanics with advanced servo-driven actuation. Unlike conventional hydraulic presses, which operate with fixed-speed pumps and mechanically constrained movement, servo hydraulic systems provide real-time control over the ram speed, force, and stroke. This allows manufacturers to achieve higher precision, improved energy efficiency, and greater flexibility in production cycles.

Key aspects of STM servo molding presses include:

Wuxi PengdaHZ Intelligent Equipment Co., Ltd., through its brand PHP (Pengda Hydraulic Press), has been at the forefront of integrating these advanced systems into fully automated production lines, serving both domestic and international markets with tailored solutions.

The application of STM servo molding presses is broad and strategically significant. They are particularly prominent in:

By offering tailored solutions for these sectors, servo molding presses allow manufacturers to meet increasingly strict industry standards while remaining cost-competitive.

The operational benefits of STM servo molding presses extend beyond basic energy savings. Key advantages include:

Modern manufacturing emphasizes not only the quality of the final product but also the sustainability and efficiency of the production process. STM servo molding presses align with these principles through:

Wuxi PengdaHZ Intelligent Equipment Co., Ltd. leverages these capabilities in its production lines, offering fully integrated solutions that combine STM servo molding press technology with automated logistics and process control.

The increasing complexity of non-metallic components, coupled with higher production volume requirements, has historically posed challenges such as:

By employing STM servo molding presses, manufacturers can mitigate these issues. Servo-driven hydraulic systems ensure precise control, reduced energy waste, and enhanced operator safety, addressing key pain points across industries.

In conclusion, the servo molding press exemplifies the next generation of hydraulic press technology, merging precision, efficiency, and safety into a single platform. For industries requiring high-quality non-metallic components—from automotive interiors to aerospace composites—these presses provide a sustainable, reliable, and technologically advanced solution.