2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

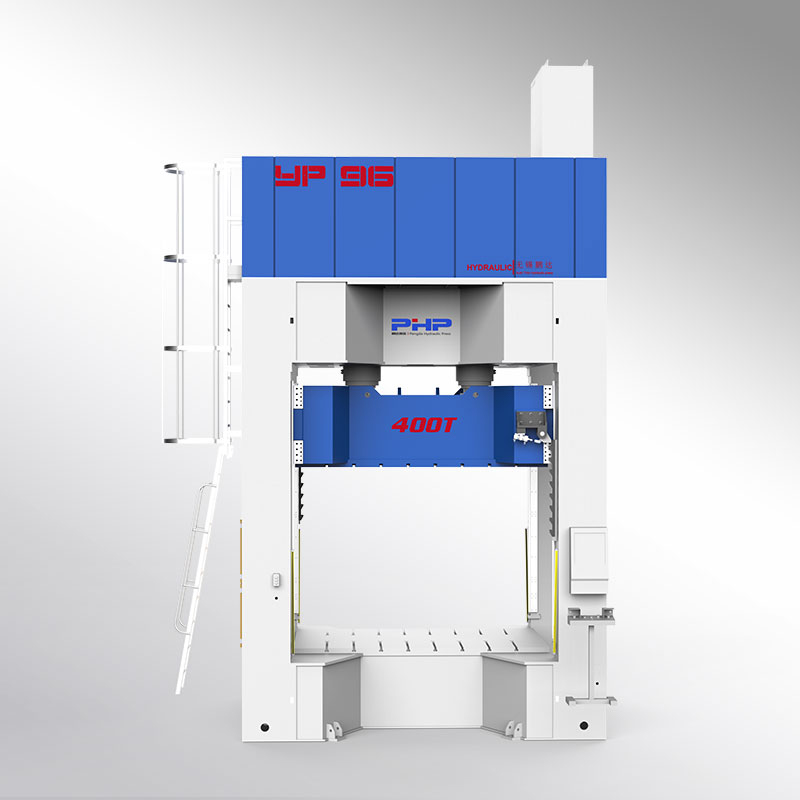

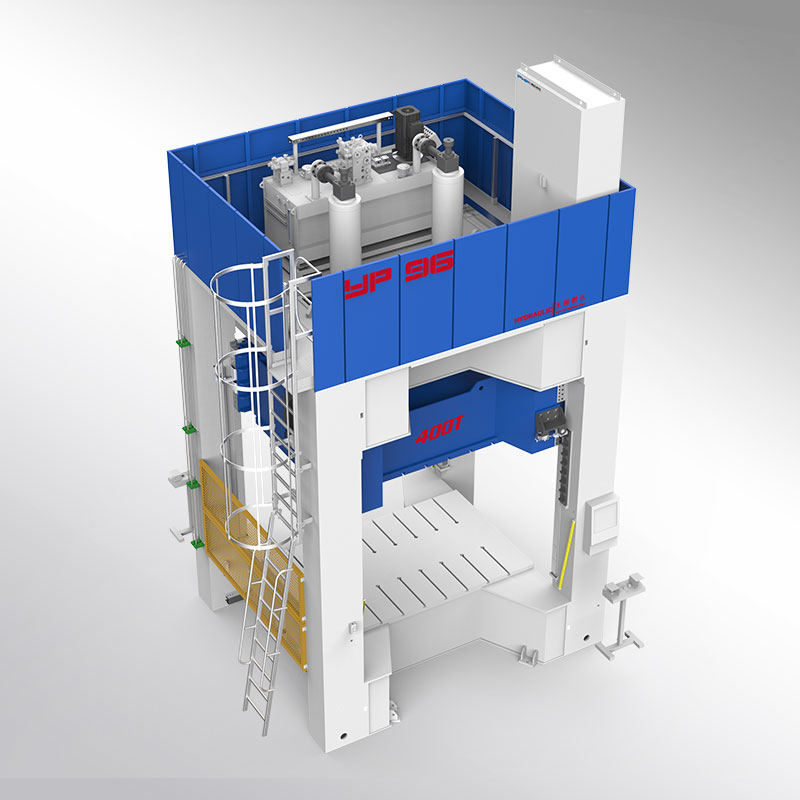

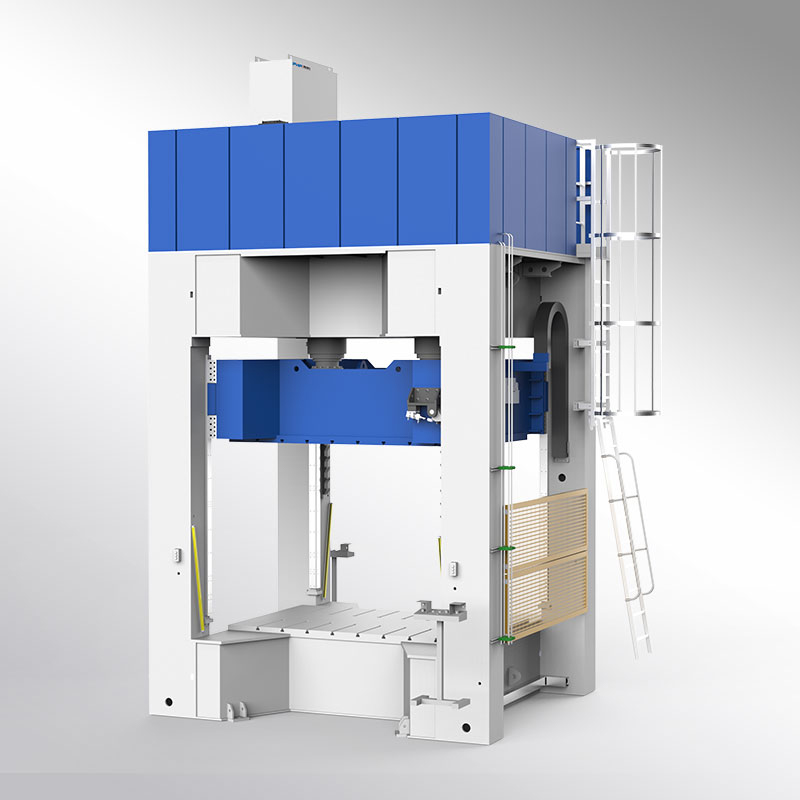

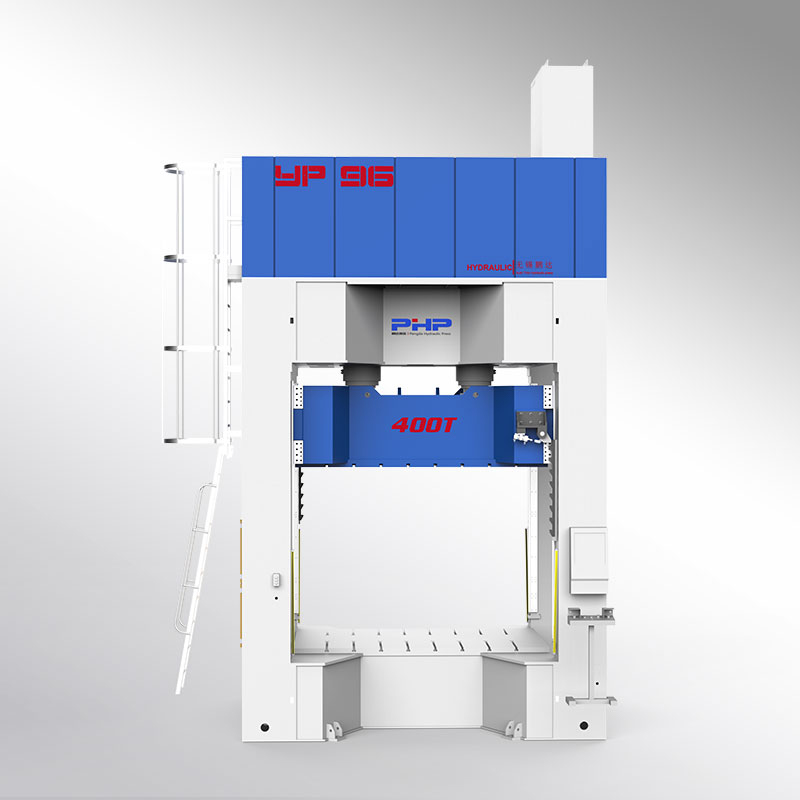

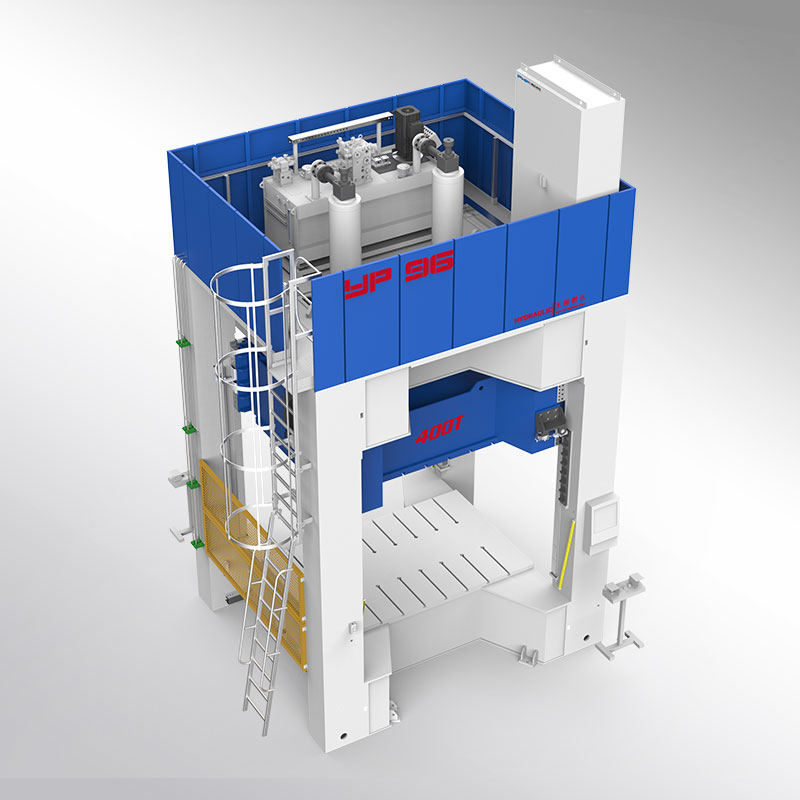

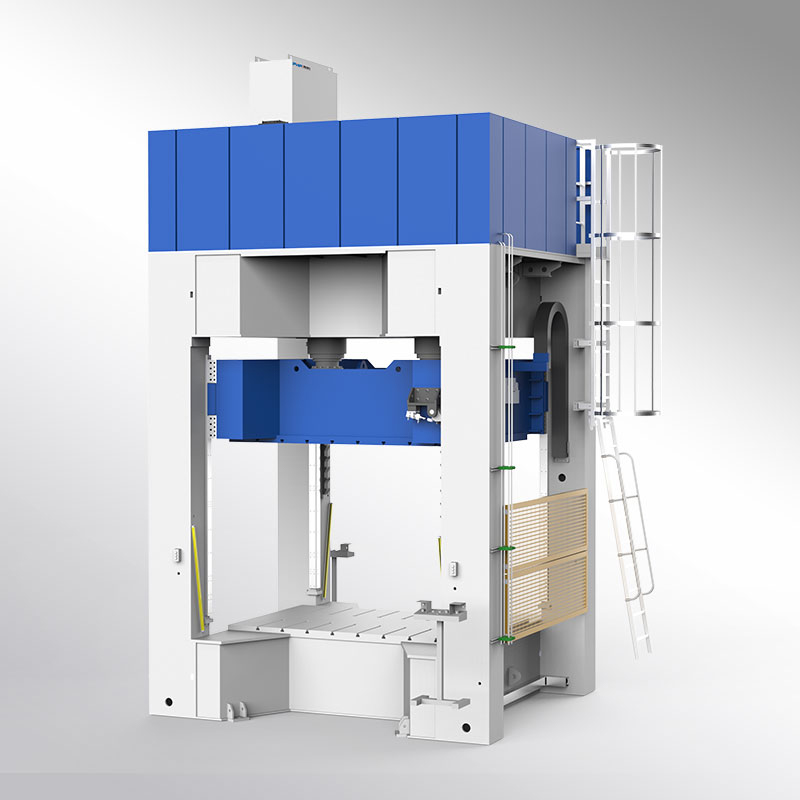

The PHP (Pengda Hydraulic Press) Automotive Roof Press is specifically designed for high-precision molding of automotive interior roofs. The equipment integrates advanced hydraulic technology with intelligent control systems, offering both stability and flexibility. It ensures that roof components outperform traditional processes in terms of strength, surface flatness, and consistency. With mature technology and a complete supporting solution, the PHP(Pengda Hydraulic Press) press not only enhances production efficiency but also helps customers reduce operating costs and strengthen market competitiveness.

Servo Auto Trim Hydraulic Press for Overhead

Precision Forming · Intelligent Efficiency · Driving the Next Upgrade in Automotive Roof Manufacturing

The PHP (Pengda Hydraulic Press) is specifically designed for the wet molding process of automotive roofs. The press features high precision and stability, a robust structure, and supports mold heating as well as quick mold change, allowing seamless integration with automated production lines. It not only enhances production efficiency and product consistency but also reduces energy consumption and labor costs, providing customers with a high-quality, high-efficiency, one-stop solution.

|

|

|

| Pressure | 200T/250T | 400T | 300T/315T | |

| Function | Fabric composite | Frame forming | General | |

| Max. Opening | 1500 | 1500 | 1500 | |

| Stroke | 1200 | 1200 | 1200 | |

| Working table size | L-R | 3000 | 3000 | 3000 |

| F-B | 1800 | 1800 | 1800 | |

| The height from working table to the floor | 700 | 700 | 700 | |

| Slider speed | Fast down | 300 | 300 | 300 |

| Slow down | 10-30 | 10-30 | 10-30 | |

| Return | 200 | 200 | 200 | |

| Power | 29 | 37 | 37 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom Overhead Hydraulic Press Manufacturers and Overhead Trimming Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

Choosing the right overhead hydraulic press is crucial for optimizing production efficiency, ensuring product quality, and reducing maintenance costs. Consider factors such as:

Evaluating these factors carefully will help you select an overhead hydraulic press that meets your production needs and ensures long-term reliability.

Overhead hydraulic presses and traditional hydraulic press systems both serve critical roles in modern manufacturing, but they differ significantly in design, efficiency, and application scope. Overhead hydraulic presses are typically optimized for energy efficiency, operational stability, and space-saving layouts, making them ideal for high-volume and complex molding processes.

PHP(Pengda Hydraulic Press), founded in 2004, is a professional manufacturer of non-metallic hydraulic presses committed to green industry principles and technological innovation. The company focuses on two main categories of non-metallic molding presses:

When compared to traditional hydraulic press systems, overhead hydraulic presses offer several advantages:

| Parameter | Typical Value |

|---|---|

| Press Capacity | 100 – 5000 kN |

| Stroke Length | 200 – 1000 mm |

| Table Size | 800 × 1200 mm – 3000 × 4000 mm |

| Automation Level | Semi-automatic / Fully automatic |

| Control System | Servo-hydraulic PLC |

| Applicable Materials | SMC, GMT, LFT-D, Carbon Fiber, HP-RTM |

Overall, overhead hydraulic presses represent a modern solution for manufacturers seeking efficiency, precision, and flexibility. By contrast, traditional hydraulic presses may still be suitable for simpler applications but generally lack the energy efficiency, automation capabilities, and space optimization offered by overhead systems.