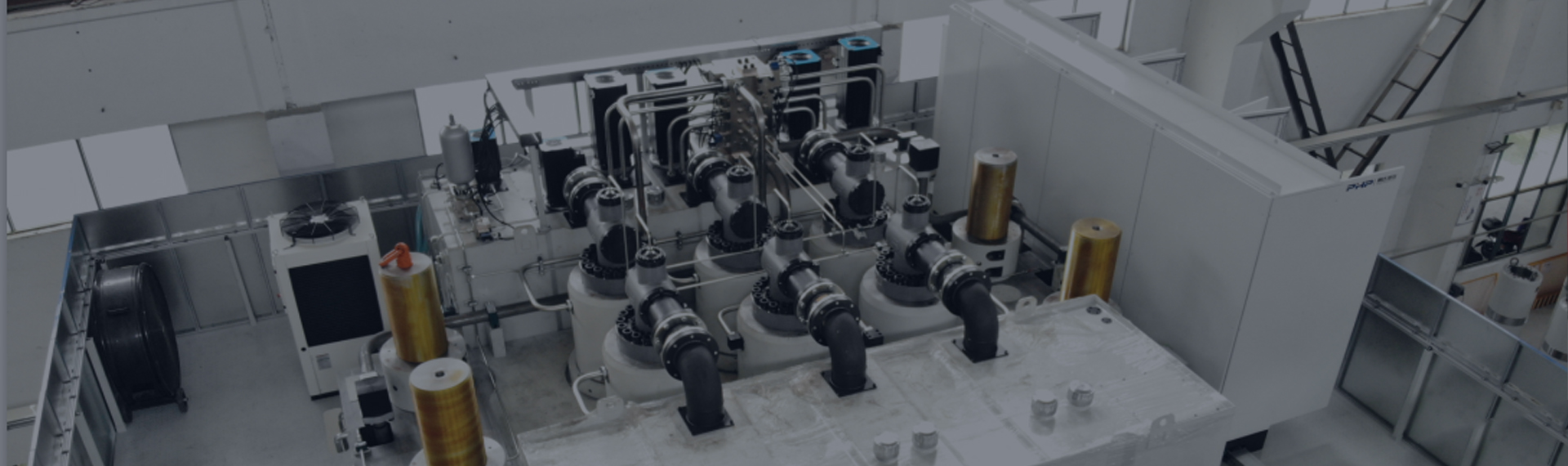

In the field of modern composite material manufacturing, the HP-RTM hydraulic press, with its high precision, high efficiency, and automation, is gradually becoming an important tool in advanced manufacturing processes. As the core equipment of the hydraulically assisted resin transfer molding (HP-RTM) process, it not only significantly improves production efficiency but also ensures the consistency and structural performance of the finished products, providing reliable support for aerospace, automotive lightweighting, and high-end equipment manufacturing.

Content

- 1 The working principle of the HP-RTM hydraulic molding machine

- 2 Advantages of the High-Pressure Hydraulic System

- 3 Intelligent Control System Enhances Molding Stability

- 4 Collaborative Design of Mold and Hydraulic System

- 5 Applications and Technological Value

- 6 FAQ: Common Questions about HP-RTM Hydraulic Forming Machines

- 6.1 Q: What types of composite material parts is the HP-RTM hydraulic forming machine suitable for producing?

- 6.2 Q: What are the requirements for the equipment and molds due to the high pressure of the hydraulic system?

- 6.3 Q: How does the HP-RTM hydraulic molding machine ensure stable quality during production?

- 6.4 Q: What are the advantages of the HP-RTM hydraulic molding machine compared to traditional low-pressure RTM?

The working principle of the HP-RTM hydraulic molding machine

The HP-RTM hydraulic molding machine is based on a high-pressure hydraulic system. Through precise control of mold closing, resin injection, and curing processes, it achieves the molding of high-quality composite material parts. The hydraulic system provides stable and adjustable pressure, ensuring optimal matching between mold closing force and injection pressure. This ensures that the resin fully impregnates the fiber preform, avoiding the generation of porosity and defects. Simultaneously, the equipment is equipped with precision sensors and a control system that can monitor pressure, temperature, and injection speed in real time, providing controllable assurance for the production of complex-shaped parts.

Throughout the molding process, the HP-RTM hydraulic molding machine achieves precise synchronization of resin injection and curing through automated control. The response speed and pressure uniformity of the hydraulic system directly affect the internal structural uniformity of the product, determining the final mechanical properties of the component. Compared to traditional low-pressure RTM processes, high-pressure hydraulic-assisted injection not only shortens the molding cycle but also increases fiber volume content, improving part rigidity and strength.

Advantages of the High-Pressure Hydraulic System

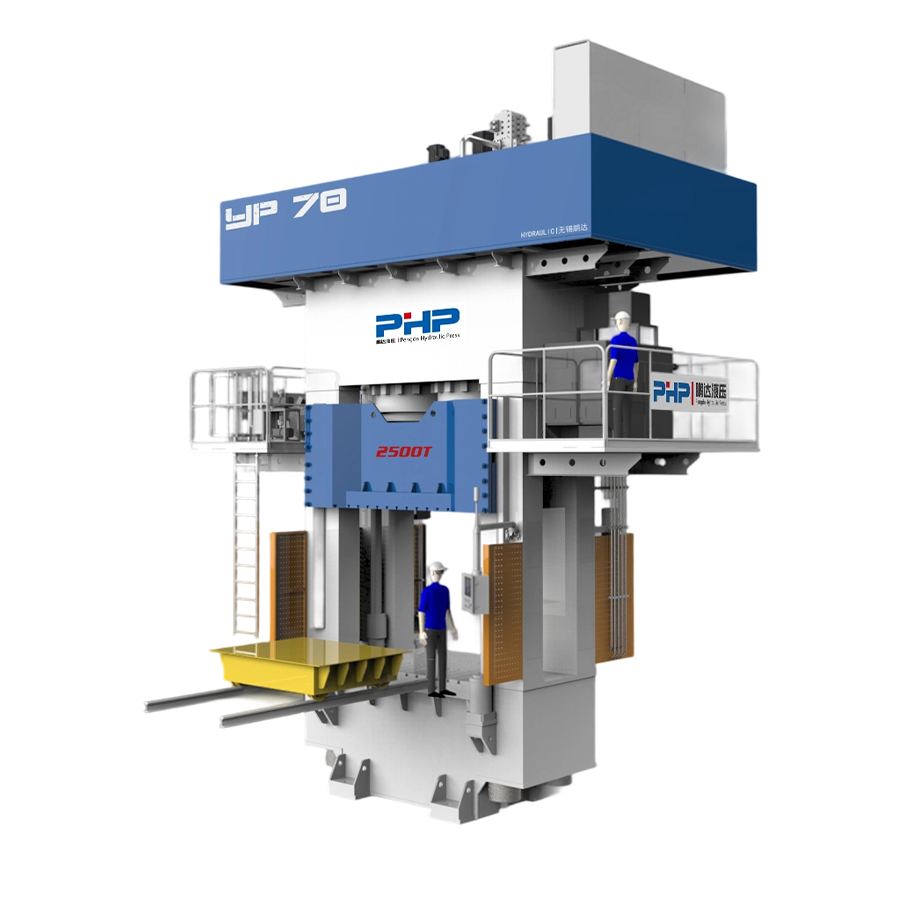

The core advantage of the HP-RTM hydraulic molding machine lies in its high-pressure hydraulic system. By driving the mold closure with a hydraulic cylinder, stable pre-compression can be achieved before resin injection, thereby improving the bonding tightness between fibers and resin. The high-pressure hydraulic injection system ensures that the resin can quickly fill the entire mold cavity even under high viscosity conditions, guaranteeing the molding quality of thick-walled parts and complex curved surfaces.

Precise control of the hydraulic system also gives the equipment greater flexibility. Whether for thin-walled structural parts or multi-layered composite materials, the HP-RTM hydraulic molding machine can achieve uniform resin distribution by adjusting the injection pressure and flow rate, avoiding localized porosity or resin retention. This precision control is particularly critical in the manufacturing of automotive structural parts and aerospace components, as these parts have extremely high requirements for strength, toughness, and dimensional accuracy.

Intelligent Control System Enhances Molding Stability

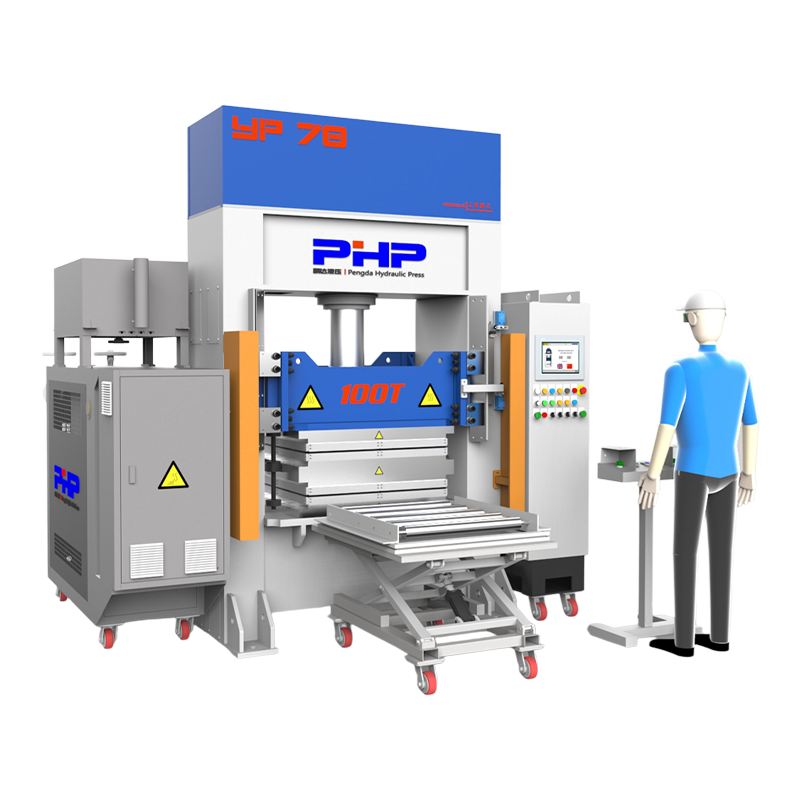

Modern HP-RTM hydraulic molding machines are typically equipped with intelligent control systems, enabling fully automated operation. Through PLC control and data feedback from pressure and temperature sensors, the equipment dynamically adjusts injection parameters and optimizes the curing curve, ensuring the repeatability and stability of the molding process. This intelligent control not only reduces human error but also significantly improves production efficiency.

The intelligent system can record and analyze process data, providing a data basis for quality control. During production, operators can monitor the injection pressure curve, mold temperature distribution, and curing progress in real time via a touchscreen, allowing for timely adjustments to process parameters to ensure that every part meets design standards.

Collaborative Design of Mold and Hydraulic System

The high performance of the HP-RTM hydraulic molding machine depends not only on the hydraulic system but also on the optimized mold design. The mold must possess high rigidity to withstand the mechanical load from high-pressure injection while ensuring uniform heat conduction and consistent resin curing. The collaborative design of the hydraulic system and the mold is a key factor in ensuring molding quality. High-rigidity molds stabilize the mold gap, preventing material leakage or deformation during injection, further improving the dimensional accuracy of the parts.

Applications and Technological Value

HP-RTM hydraulic forming machines are widely used in the manufacturing of high-performance composite material parts. Their high-pressure, high-precision, and intelligent control advantages make them important in automotive lightweighting, aerospace structural components, high-end sporting goods, and new energy equipment. By precisely controlling injection pressure and the curing process, the equipment can produce parts with complex shapes and high fiber volume ratios, significantly improving material utilization and mechanical properties.

For enterprises, adopting HP-RTM hydraulic forming machines means a more controllable production process, more stable product quality, and reduced material waste and rework rates. Its high degree of automation and intelligence also reduces reliance on operator skills, enabling large-scale production while ensuring a stable output of high-precision parts.

FAQ: Common Questions about HP-RTM Hydraulic Forming Machines

Q: What types of composite material parts is the HP-RTM hydraulic forming machine suitable for producing?

A: Primarily suitable for composite material parts with high fiber volume content and complex structures, especially in applications requiring high precision and high strength, such as automotive structural components, aerospace parts, and high-performance sporting goods.

Q: What are the requirements for the equipment and molds due to the high pressure of the hydraulic system?

A: The hydraulic system of the equipment needs to ensure stable and adjustable high-pressure output, while the mold must possess high rigidity and pressure resistance to withstand the mechanical load during the injection process and ensure the molding accuracy and structural uniformity of the parts.

Q: How does the HP-RTM hydraulic molding machine ensure stable quality during production?

A: Through a smart control system that monitors pressure, temperature, and injection speed in real time, combined with data recording and analysis, dynamic adjustment of injection parameters is achieved, ensuring the controllability of the molding process and the consistency of part quality.

Q: What are the advantages of the HP-RTM hydraulic molding machine compared to traditional low-pressure RTM?

A: High-pressure hydraulic injection can quickly fill the mold, shorten the molding cycle, improve the fiber volume ratio and mechanical properties, while reducing porosity and resin retention, achieving high-precision and highly consistent part production.

The HP-RTM hydraulic molding machine, through the perfect combination of a high-pressure hydraulic system and intelligent control, has become an important piece of equipment for manufacturing high-performance composite material parts. Its advantages in precision, production efficiency, and product stability provide reliable technical support for various high-end manufacturing enterprises, making high-quality development of the composite material industry possible.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский