2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

Sheet Molding Compound (SMC) is a type of pre-impregnated, fiber-reinforced thermoset composite material. It is composed of chopped glass fibers, unsaturated polyester or vinyl ester resin, fillers, and various additives, and is processed into sheets through mixing, impregnation, and sheet-forming techniques. Widely used in the automotive, railway, electrical, and construction industries, SMC technology offers excellent mechanical properties, dimensional stability, and flame retardancy.

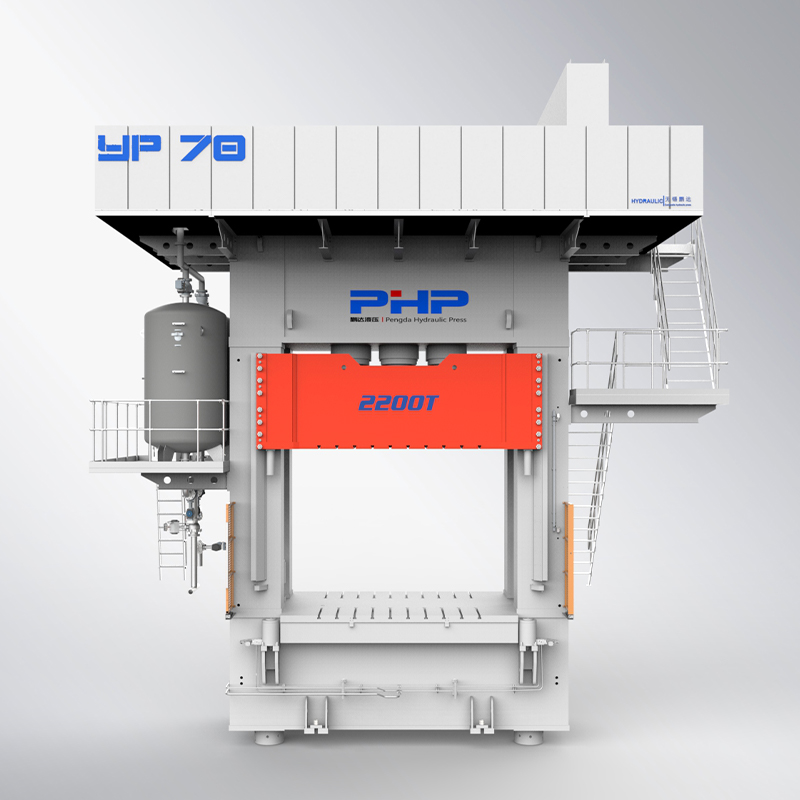

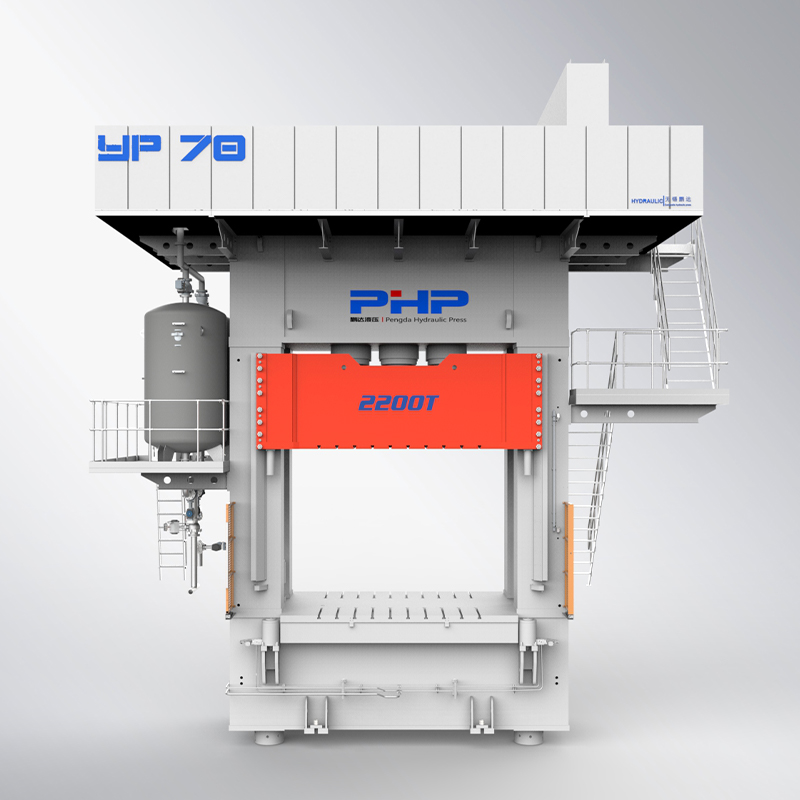

SMC Servo Composite Hydraulic Press

Complete Professional FRP/SMC Molding Solutions

SMC servo molding press is widely used in new energy vehicles, rail transit, urban construction, military products, low-voltage electrical and other fields.

Compared with the traditional molding press, PHP(Pengda Hydraulic Press) hydraulic press is safer, more energy-saving, more environmentally, and stable fast - slow speed makes the surface finish of the product higher.The excellence of the manufacturing process greatly reduces the downtime of the press, and brings higher benefits to our customers.

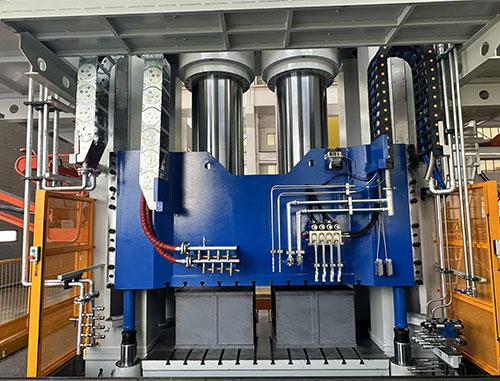

● Frame structure to ensure equipment stability.

● Servo system ensures stable operation, energy saving and reliability.

● A variety of safety protection measures to keep the machine safe and reliable.

● Faster down and return speed effectively improve the production cycle.

● Metal sleeve seal and SAE flange connection, pipe without welding, completely eliminate oil leakage points.

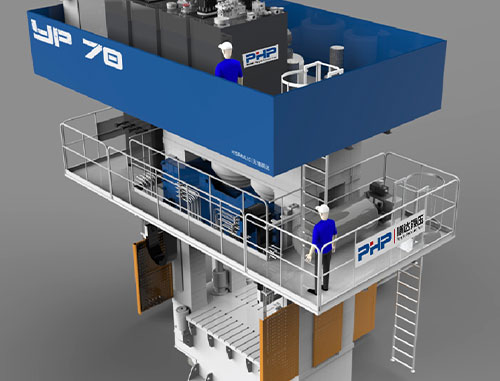

● The hydraulic unit and electrical cabinet are placed on the upper platform.

● A two-layer platform is added for placing auxiliary equipment such as oil heater and vacuum system, effectively saving floor space.

|

|

|

| Truck Parts | EV Battery Cover | Bus Overhead |

|

|

|

| Manhole Cover | Wash Basin |

| Type | Unit | 500 | 1000T | 1600T | 2000T | 2500T | 3000T | 4000T | 5000T | 6000T | |

| Max. fluid pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Max. Opening | mm | 1600 | 2000 | 2200 | 2400 | 2400 | 2600 | 3500 | 3500 | 3500 | |

| Max. Stroke | Mm | 1200 | 1600 | 1800 | 2000 | 2000 | 2200 | 3000 | 3000 | 3000 | |

| Working table size | L-R | mm | 1500 | 2400 | 2800 | 3000 | 3500 | 3500 | 4000 | 4200 | 4500 |

| F-B | Mm | 1500 | 1600 | 2000 | 2000 | 2500 | 2500 | 3000 | 3200 | 3200 | |

| Speed | Fast down | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Pressing | mm | 1-20 | 1-20 | 1-20 | 1-20 | 1-20 | 1-20 | 1-20 | 1-20 | 1-20 | |

| Slow return | mm | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | 20-50 | |

| Fast return | mm | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Power | mm | 32 | 40 | 67 | 75 | 80 | 130 | 175 | 255 | 284 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom SMC Servo Molding Press Manufacturers and SMC Hydraulic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

In the composite material manufacturing sector, SMC (Sheet Molding Compound) forming has become a core process for automotive exterior panels, rail transit interiors, electrical insulation components, and new energy device enclosures. Over the past decade, traditional hydraulic presses have long dominated this field. However, with the industry's shift toward high-performance, green production and digital management, a new type of equipment has rapidly gained attention—the SMC Servo Molding Press. It not only changes the way forming equipment is controlled but also enables manufacturers to transition from simply "being able to produce" to "producing better, more stable, and more controllable products."

The most significant difference between SMC servo hydraulic presses and traditional presses is not in structural design but in control capabilities. SMC materials have directional fibers and limited flow windows, and traditional hydraulic presses largely rely on manual experience for adjustment. This often results in inconsistent process curves, slow response, and reliance on manual correction during critical stages such as holding pressure, venting, and mold closing. While this might have been acceptable in the past, today’s products are larger, appearance tolerances are tighter, and customers demand higher batch consistency. Manufacturers must make processes transparent, traceable, and reproducible. The servo system addresses these challenges by digitally controlling pressure, speed, and stroke in real-time, allowing operators to precisely set each stage as if conducting a chemical experiment. This capability transforms SMC production from "experience-based manufacturing" to "parameter-driven manufacturing," naturally improving product dimensions, thickness, and surface consistency.

At the same time, servo technology turns energy-saving from a slogan into reality. Traditional hydraulic systems operate pumps continuously, consuming energy even when no actions are being performed. Servo systems only supply power when necessary, significantly reducing electricity waste. For SMC forming, which involves short and frequent cycles, this energy efficiency is particularly significant. Reduced heat generation lowers cooling demands, extends oil life, and decreases maintenance costs. For large-scale production, these savings translate into tangible long-term cost benefits and improved efficiency.

SMC forming is no longer just a matter of pressing a button. Modern factories increasingly integrate robotic handling, automatic material feeding, production line conveyance, MES connectivity, energy monitoring, and anomaly alerts. Traditional hydraulic presses, lacking sufficient data interfaces and feedback capabilities, struggle to integrate into this digital environment. By contrast, SMC Servo Molding Presses naturally support data transmission, digitally recording every step from mold closing to pressing, venting, holding pressure, and demolding. Managers can retrieve real-time production data, engineers can analyze processes, and manufacturers gain reliable operational insights, enabling informed decision-making and cost optimization.

Feedback from the industry shows that SMC Servo Molding Presses have clear advantages in automotive, rail transit, electrical manufacturing, and new energy sectors. Especially for exterior and structural components, companies experience higher product yields, reduced batch variability, better control of production rhythms, and lower training costs for new staff.

Wuxi PengdaHZ Intelligent Equipment Co., Ltd., under the PHP (Pengda Hydraulic Press) brand, has over 20 years of experience in hydraulic press development and manufacturing. Unlike companies with multiple product lines, Pengda focuses solely on hydraulic presses, with R&D, innovation, manufacturing, and service all centered on this field. This dedication allows continuous improvement in hydraulic control, servo drive solutions, energy-saving algorithms, and digital data interfaces, building a robust technical foundation.

Pengda hydraulic presses are widely applied across automotive exteriors and structural components, rail transit, construction materials, aerospace composites, and automotive interior production. Long-term performance verification in mass production ensures that our equipment not only produces reliably but also supports intelligent, data-driven manufacturing.

In the next five years, the competition for composite material forming equipment will focus less on hardware alone and more on process transparency, energy efficiency, and real-world application performance. SMC Servo Molding Presses help manufacturers achieve better process consistency, lower energy consumption, more controllable production rhythms, and higher management transparency, bringing SMC production into a new era of high efficiency, precision, and traceability.

If your company is planning to expand an SMC production line or upgrade existing equipment, PHP (Pengda Hydraulic Press) offers solutions that not only provide machines but also deliver tangible improvements in production efficiency, product quality, and future manufacturing capabilities.