2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

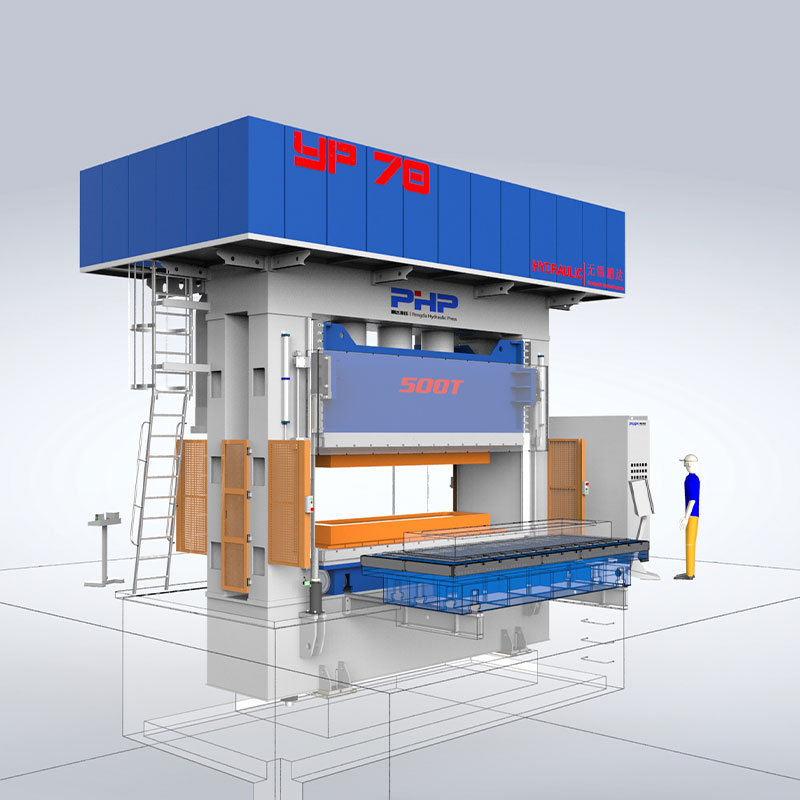

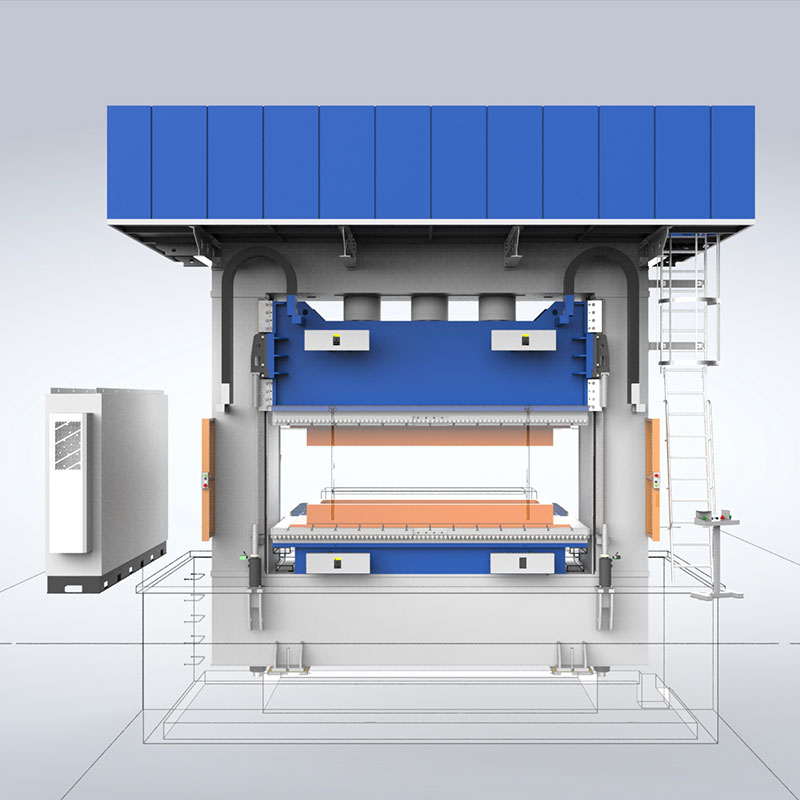

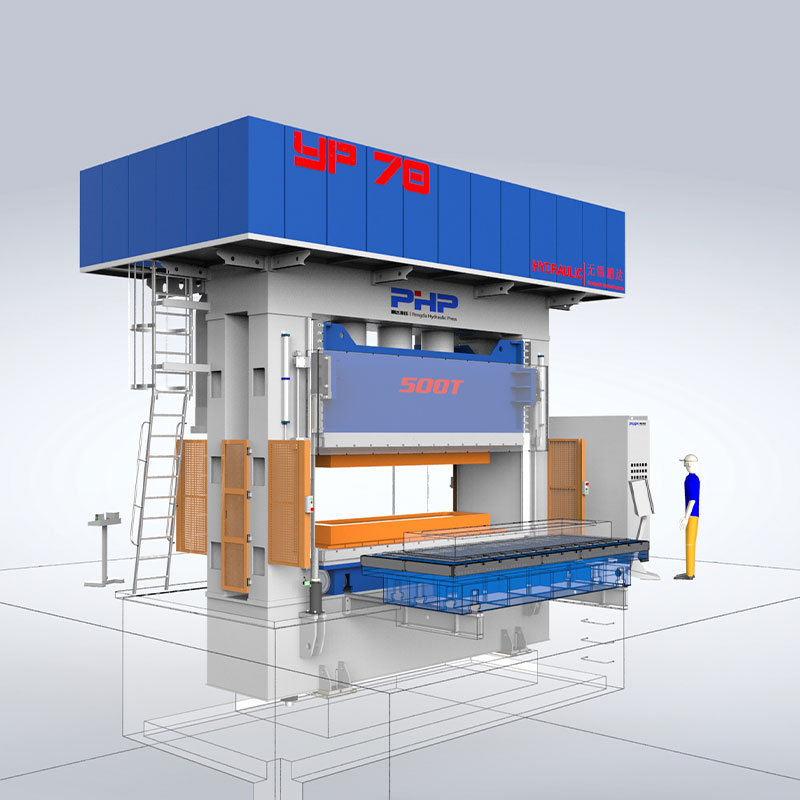

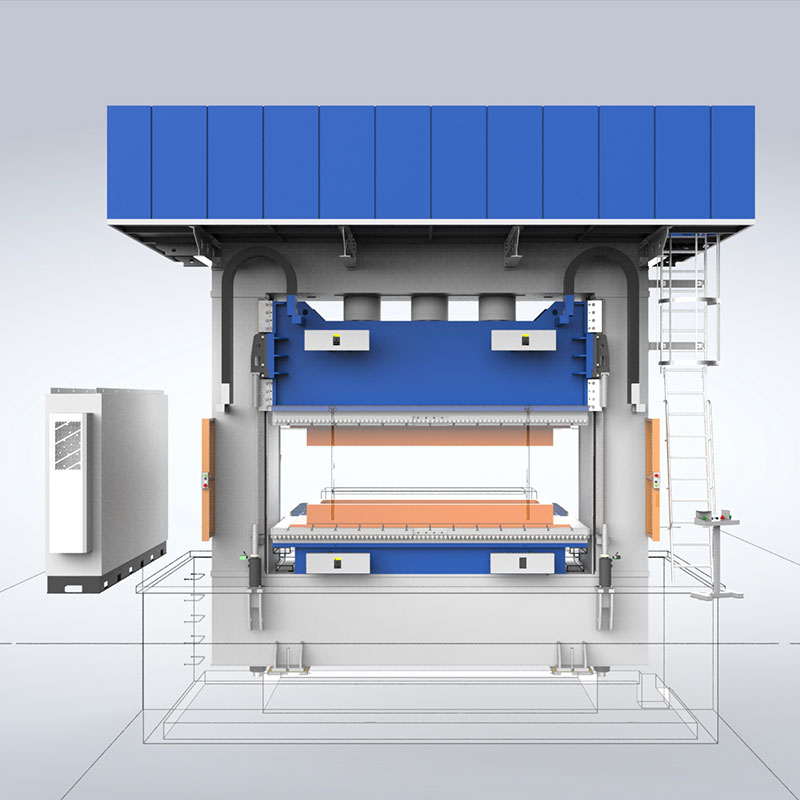

The RTM press for low-pressure injection is a press that heats and shapes the prepreg material after it is placed into the mold, layered, and injected with resin. This press has heating and cooling processes, and sometimes is equipped with a moving table according to process requirements, which can simultaneously lay and form materials to achieve the goal of improving production efficiency.

RTM Composite Press

Heating / Cooling / Moving Table

Pengda's composite press is a special equipment for low pressure RTM process. The RTM process is becoming increasingly important in the growing lightweight engineering sector, not only in the aerospace industry and automotive, where carbon fiber reinforced polymers (CFRP) and other fiber composites are becoming more widely used. Pengda provides one-stop solution for RTM press..

|

|

|

| Carbon Fiber Engine Hood | Carbon Fiber Engine Hood | 2 |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom RTM Molding Press Manufacturers and RTM Composite Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

Resin Transfer Molding RTM molding presses play a crucial role in advancing modern composite manufacturing. By combining controlled resin injection with closed mold pressure forming, RTM molding presses significantly enhance both production efficiency and part quality.

RTM molding presses allow simultaneous resin injection and curing within a closed mold, which shortens cycle times compared to traditional hand lay up or vacuum assisted processes. Automated press control ensures consistent clamping pressure, enabling faster curing and higher throughput for medium to high volume production.

Because RTM uses rigid matched molds and controlled pressure, the resulting composite parts exhibit excellent dimensional accuracy and repeatability. The press maintains uniform mold closure, preventing deformation and ensuring that each part matches exact tolerances, critical for automotive, aerospace, and industrial components.

RTM molding presses create stable pressure conditions that promote even resin flow through the fiber preform. This reduces dry spots, voids, and uneven saturation, leading to stronger, more reliable mechanical properties. Consistent resin distribution is essential for structural composite applications.

Closed mold processing produces smooth, near net shape surfaces on both sides of the component. This reduces or eliminates secondary finishing operations such as sanding or coating, lowering labor costs and improving overall production efficiency.

The injection controlled process minimizes excess resin usage, and closed mold containment prevents overflow or spillage. This reduces material waste, enhances cost efficiency, and supports more sustainable production practices.

Modern RTM molding presses integrate easily with automated loading systems, robotic handling, and curing process monitoring. This increases production consistency, reduces labor dependence, and allows manufacturers to scale operations with minimal error.

Thanks to controlled fiber alignment, resin flow, and curing pressure, components produced using RTM presses deliver superior strength to weight ratios and more reliable performance under stress, ideal for high performance composite applications.

RTM molding presses significantly improve composite manufacturing by delivering faster cycle times, enhanced dimensional precision, and more consistent material properties. Their ability to integrate with automation and reduce material waste makes RTM a preferred solution for industries seeking high quality, scalable composite production.

Resin Transfer Molding RTM molding presses have become an increasingly important technology in modern composite manufacturing. Compared with traditional forming methods such as hand lay up, vacuum infusion, and compression molding, RTM offers clear advantages in efficiency, repeatability, and product performance.

As a professional manufacturer of non-metallic hydraulic presses, PHP(Pengda Hydraulic Press) focuses on technological innovation, energy-saving systems, and high stability equipment design. Its servo composite hydraulic presses support multiple advanced molding processes, including SMC, LFT D, GMT, HP RTM, STM, and carbon fiber high-temperature forming. This provides strong engineering support for industries such as new energy vehicles, aerospace, rail transit, low-voltage electrical appliances, and urban construction.

Uses matched rigid molds and controlled injection pressure to infuse resin into a preform. Suitable for medium to high volume, structurally demanding composite parts.

Includes hand lay up, vacuum infusion, compression molding, and open mold processes. Each method varies in cost, precision, and production speed.

RTM uses closed metallic molds and pressurization, ensuring consistent thickness, better fiber resin distribution, and repeatable tolerances.

Simultaneous resin injection and curing inside the press significantly reduces cycle times compared to manual or vacuum only processes.

No open surfaces means reduced emissions, improved workplace cleanliness, and better-quality surfaces on both sides of the component.

RTM enables deeper resin penetration, lower void content, and more uniform fiber wet out, resulting in stronger and lighter parts.

Pressure control systems, servo drive technology, and automated loading solutions make RTM more suitable for modern high volume production.

Equipment and mold investment is higher than traditional hand lay up or vacuum infusion.

Requires precise control of injection parameters, resin viscosity, mold sealing, and press pressure settings.

Open mold or vacuum infusion methods may still be more suitable for oversized, low volume components.

Pros: High precision, low void content, excellent surface finish, short production cycles, suitable for mass production, stable and clean closed mold environment, automation friendly.

Cons: Higher equipment and mold cost, requires skilled engineering setup, less economical for very large, low volume parts.

Pros: Lower cost for small scale production, flexible for large, custom, or prototype parts, simple setup and tooling.

Cons: Labor intensive, lower dimensional repeatability, more material waste, longer production cycles, limited automation potential.

(Generalized table for industry reference; not specific to any model)

| Parameter | Typical Range |

|---|---|

| Press Capacity | 100–3000 tons |

| Daylight | 600–2500 mm |

| Stroke | 400–1600 mm |

| Working Table Size | 800×800 mm to 3000×3000 mm |

| Heating Method | Electric, oil, or steam heating |

| Temperature Range | Up to 350 degrees |

| Pressure Control | Servo closed-loop, high-precision control |

| Resin Injection Pressure | 5–150 bar depending on application |

| Automation Options | Robotic loading, preform placement, trimming |

RTM molding presses offer significant improvements in efficiency, repeatability, and structural performance compared with traditional composite forming methods. While the initial investment is higher, RTM provides long term advantages for mass production, advanced composite applications, and industries requiring strong, lightweight, and dimensionally accurate components.

With nearly two decades of specialization in non-metallic hydraulic presses, PHP(Pengda Hydraulic Press) continues to deliver stable, energy efficient, and reliable solutions that support evolving composite manufacturing needs across global markets.