2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

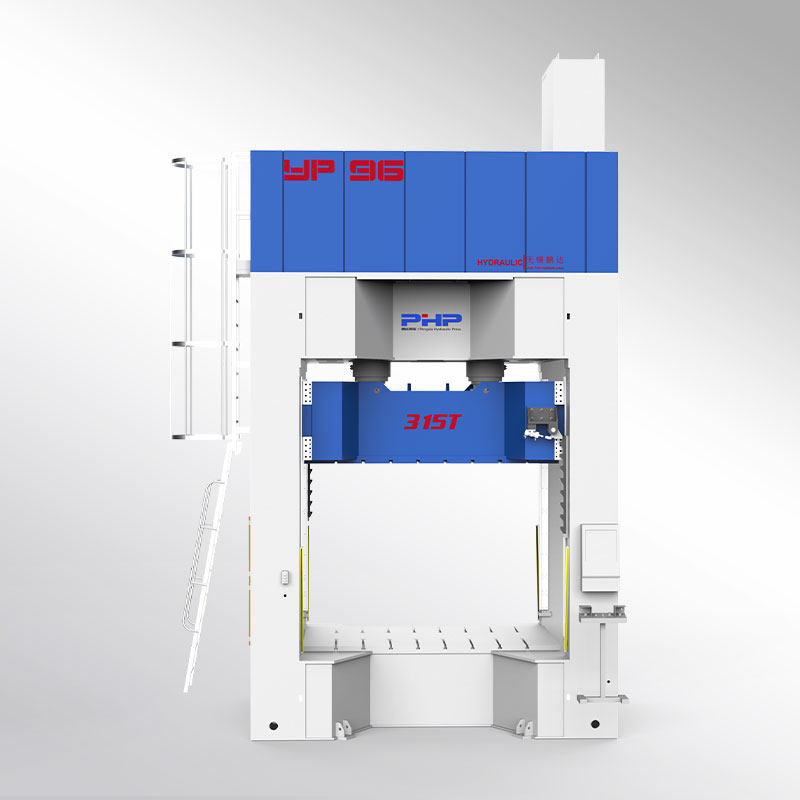

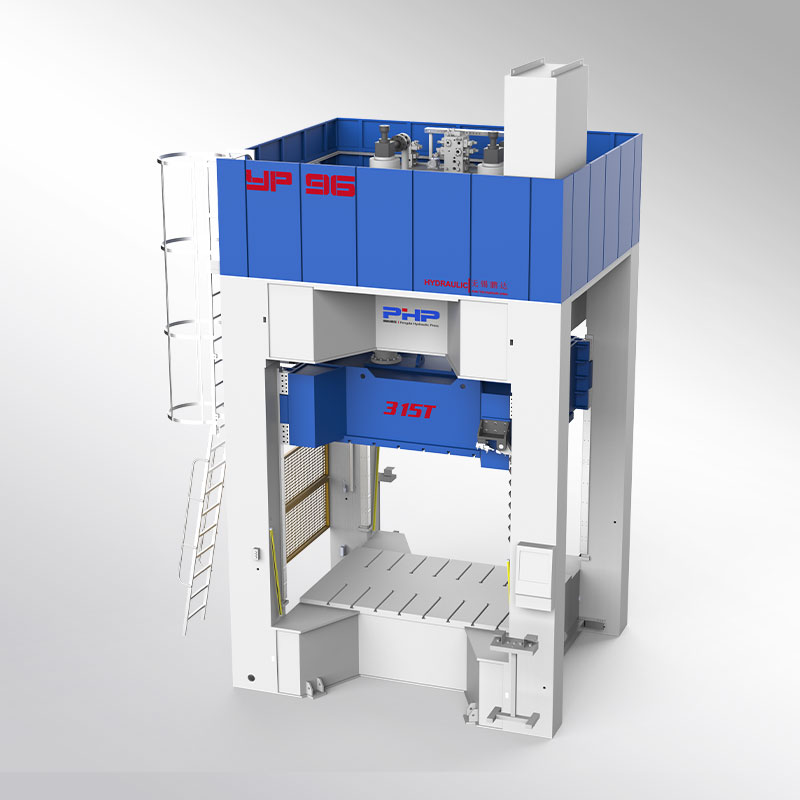

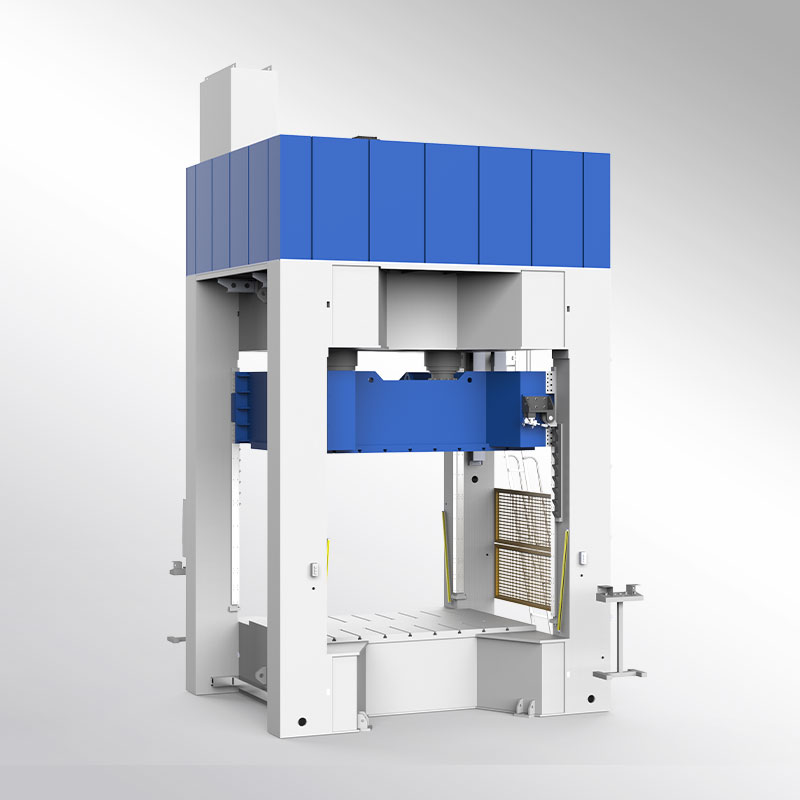

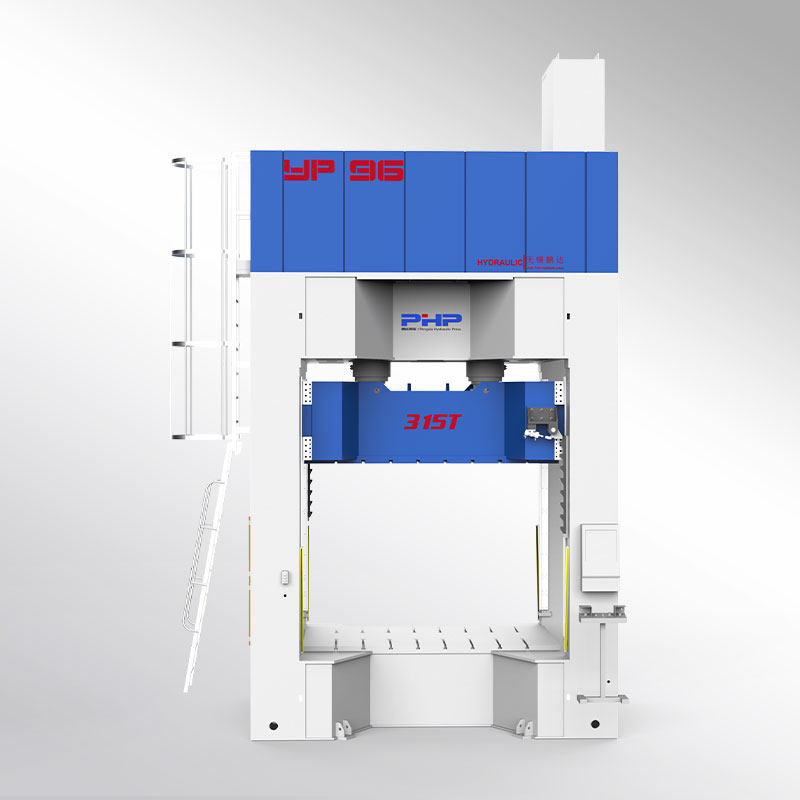

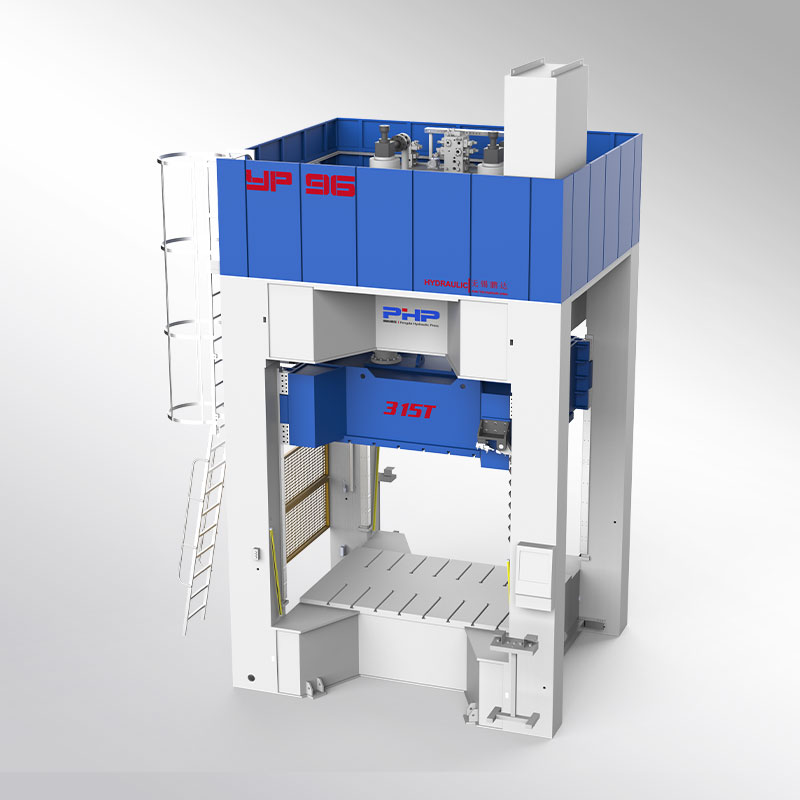

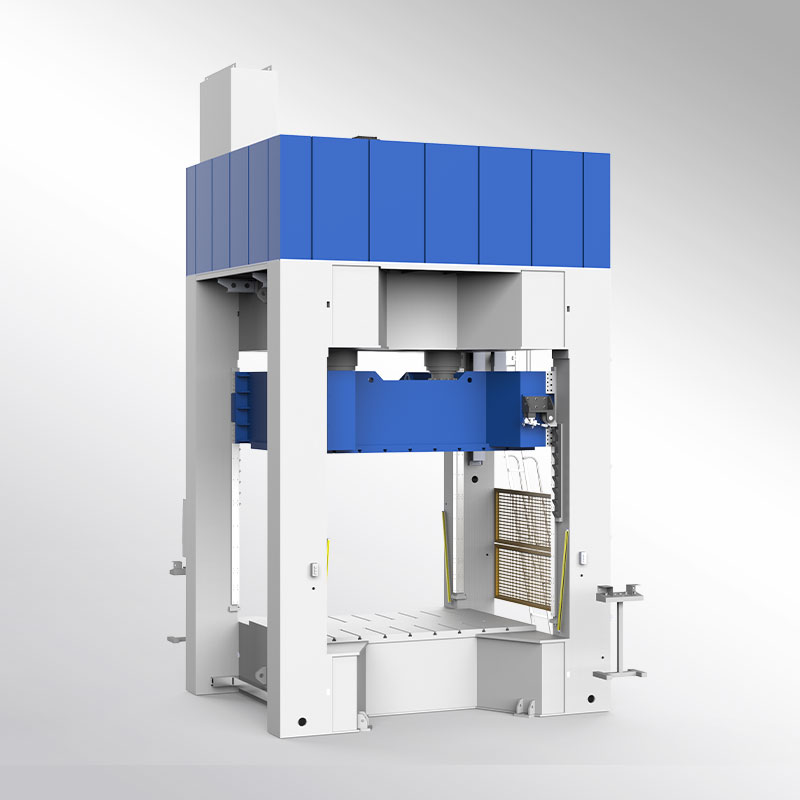

The Automotive Carpet Hydraulic Press from Wuxi Pengda is specifically developed to meet the forming requirements of automotive carpets. The press combines a high-performance hydraulic system with intelligent servo control, ensuring complex process demands are met while also saving energy and maximizing production efficiency, helping customers achieve high-quality, cost-effective manufacturing solutions.

Servo Auto Trim Hydraulic Press for Carpet

Precision Forming, Reliable Performance

With high precision, energy efficiency, and stable reliability, the PHP(Pengda Hydraulic Press) Automotive Carpet Hydraulic Press not only enhances production efficiency and product quality, but also helps customers reduce manufacturing costs and strengthen market competitiveness, making it an ideal solution for automotive carpet forming.

With The Following Features, The Php Automotive Carpet Hydraulic Press Delivers Efficient, Precise, And Safe Forming Operations:

● Energy-efficient servo drive: Reduces energy consumption and enables sustainable production.

● Optimized structure, stable operation: Maintains reliable performance during long-term continuous production.

● High-precision forming: Ensures product consistency and minimizes defects.

● Safety design: Fully compliant with safety standards for secure operation.

|

|

|

| Pressure | 50T | 315T | |

| Function | Material preheating | Forming | |

| Max. Opening | 600 | 2400 | |

| Stroke | 600 | 1800 | |

| Working table size | L-R | 3000 | 3000 |

| F-B | 2000 | 2000 | |

| The height from working table to the floor | 900 | 700 | |

| Slider speed | Fast down | 200 | 300 |

| Slow down | 5-15 | 10-30 | |

| Return | 150 | 200 | |

| Power | 21 | 44 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom Carpet Hydraulic Press Manufacturers and Carpet Hydraulic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

In the evolving landscape of automotive interior manufacturing, carpet production presents unique challenges that demand specialized solutions. PHP (Pengda Hydraulic Press), with nearly two decades of expertise in non-metallic hydraulic presses, offers innovative approaches through its specialized Carpet Hydraulic Press technology. Here are five key insights that demonstrate how modern hydraulic press technology is transforming automotive carpet manufacturing.

Modern automotive carpets require sophisticated three-dimensional configurations that must perfectly conform to vehicle floor contours while integrating multiple material layers. PHP's Servo Interior Parts Hydraulic Presses are specifically engineered to address these complex requirements through advanced technological capabilities.

Founded in 2004 with a firm commitment to green industry principles and technological innovation, PHP has pioneered energy-efficient solutions that deliver both environmental sustainability and economic advantages. The servo-hydraulic technology represents a significant advancement in sustainable manufacturing practices.

PHP's comprehensive approach extends beyond individual machines to complete fully automated production lines that integrate seamlessly with modern manufacturing ecosystems. This integrated methodology has earned strong recognition from automotive manufacturers and Tier 1 suppliers worldwide.

Contemporary automotive carpets involve complex material structures that demand more than basic molding processes. PHP's expertise in Servo Interior Parts Hydraulic Presses specifically addresses the unique challenges of working with modern composite materials and multi-layer structures.

PHP's twenty-year specialization philosophy centers on delivering stable and reliable non-metallic presses that address the fundamental concerns of automotive manufacturers: equipment reliability, product consistency, and long-term operational costs in high-volume production environments.

The evolution of automotive carpet manufacturing requires specialized expertise and reliable technology partnerships. PHP (Pengda Hydraulic Press) combines nearly twenty years of focused experience in non-metallic press technology with an unwavering commitment to innovation and customer success. By addressing the specific challenges of automotive carpet production—from complex geometries and multi-material composites to energy efficiency and automation integration—PHP enables manufacturers to meet the demanding quality standards of the global automotive industry while maintaining competitive production costs.

Through continuous dedication to mechanical design excellence, standardized key systems, and responsive global service, PHP maintains its position as a trusted partner for automotive manufacturers and suppliers seeking to optimize their interior component production capabilities and achieve zero-defect manufacturing targets.