2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

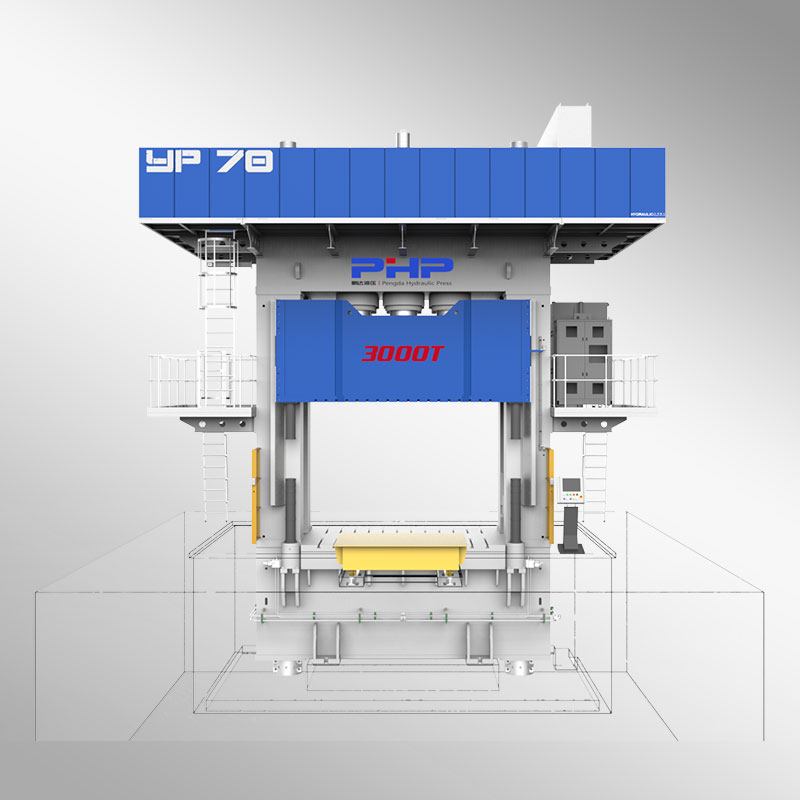

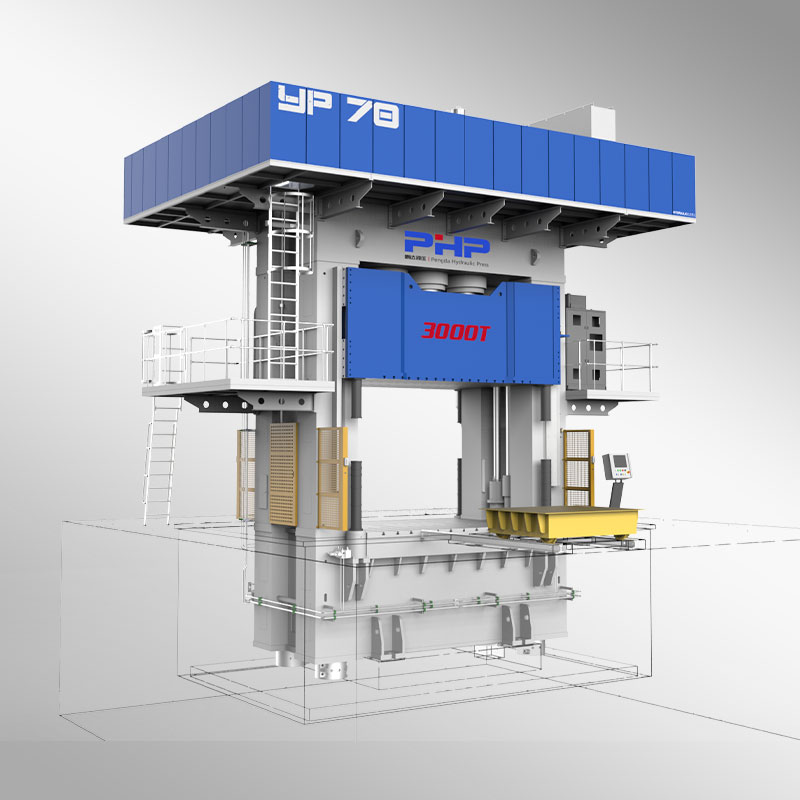

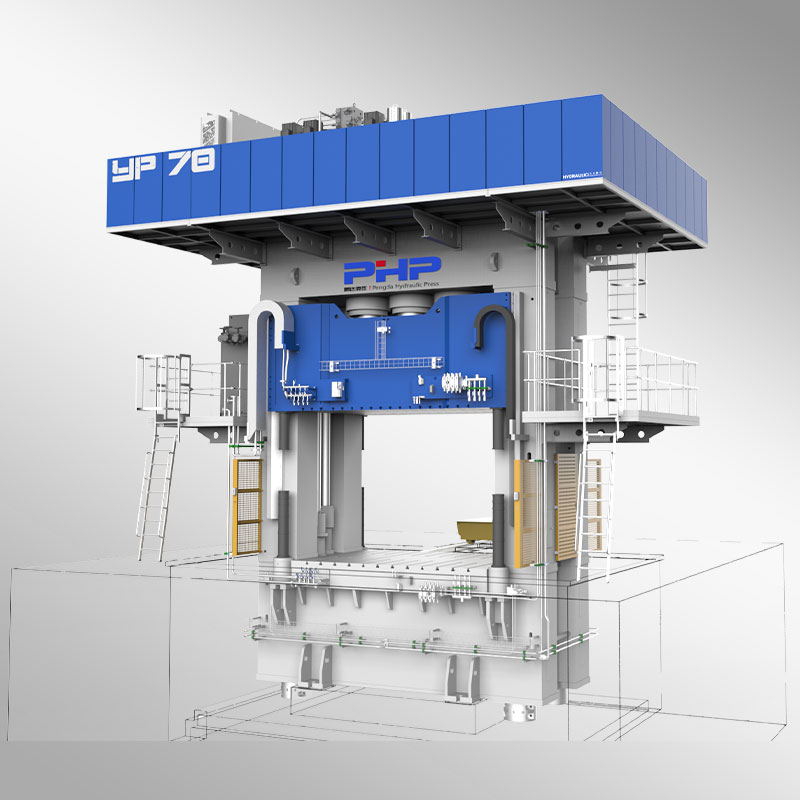

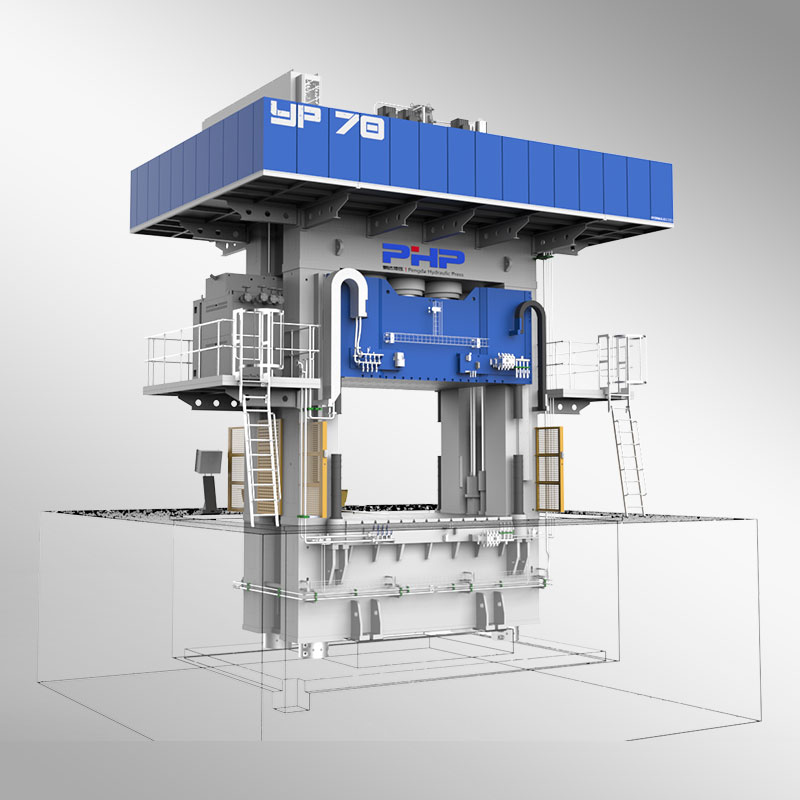

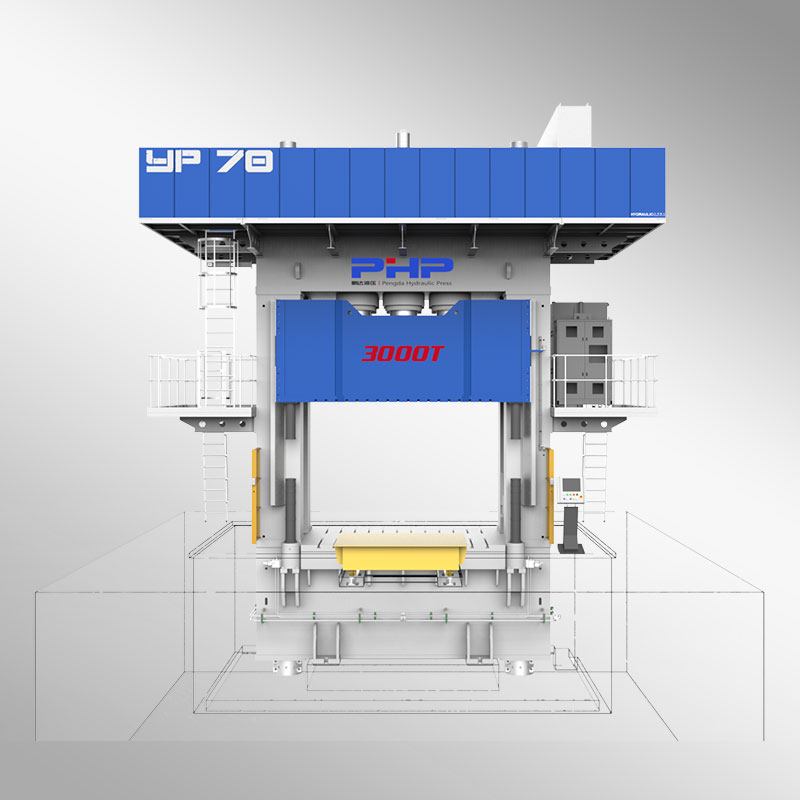

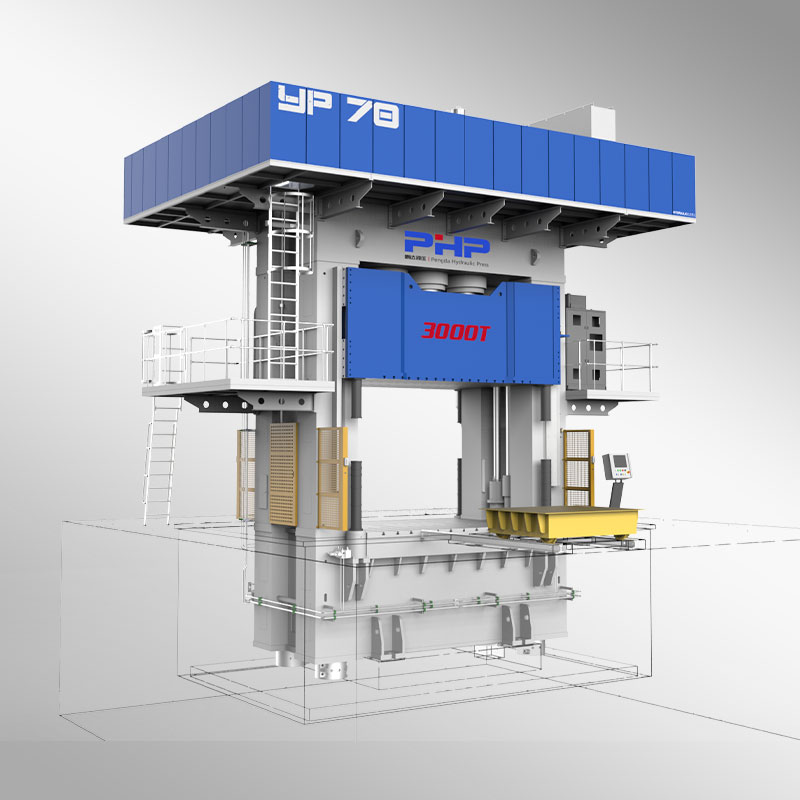

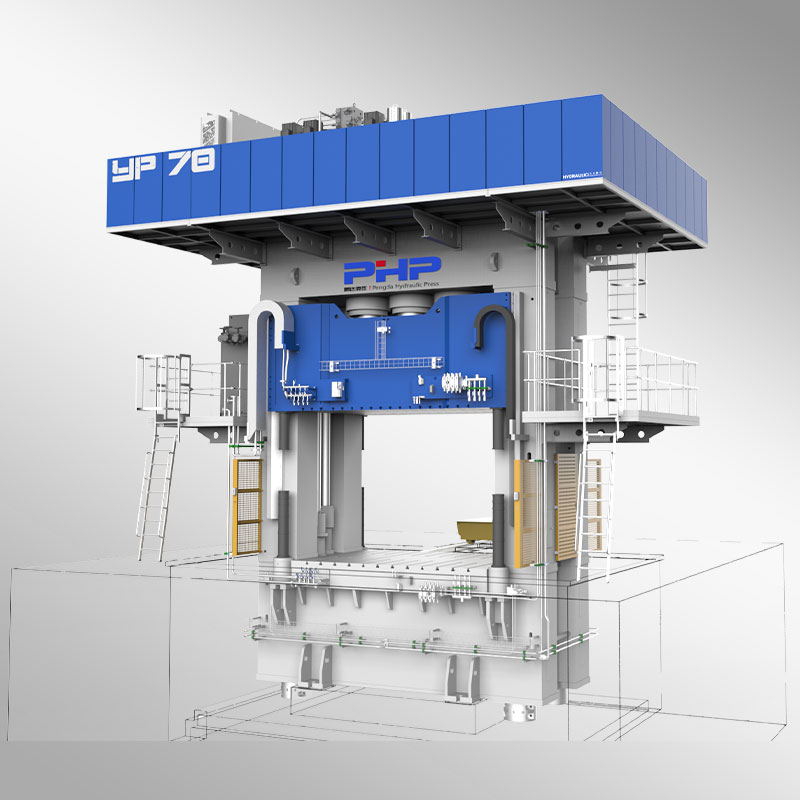

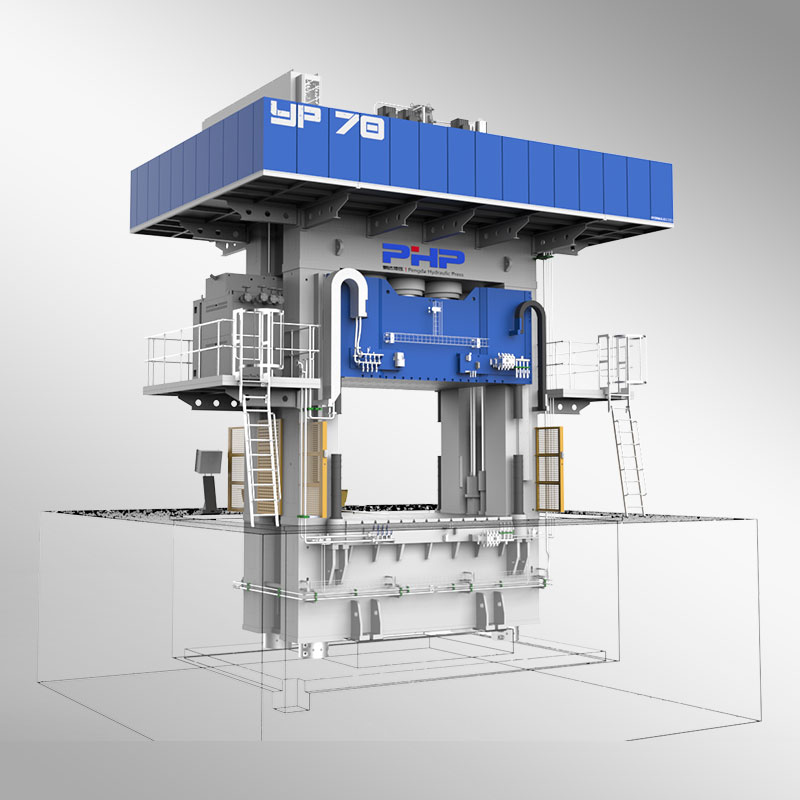

The GMT (Glass Mat Thermoplastics) press is engineered for high-efficiency molding of fiber-reinforced thermoplastic materials. Ideal for lightweight structural parts in the automotive, construction, and industrial sectors, the GMT press delivers precise forming under controlled heat and pressure. Key advantages include fast cycle times, high part strength, and excellent repeatability. Typical applications include underbody shields, door panels, and seat structures—helping manufacturers meet demanding performance and weight reduction targets.

GMT Servo Composite Hydraulic Press

Thermoset Composite Molding Process

GMT presses are mainly used for particularly formable materials made of thermosetting resins and reinforced glass fibers.This technique is particularly suitable for complex, precisely dimensioned parts as an alternative to steel or aluminum.

PHP(Pengda Hydraulic Press) according to the requirements of customers, tailor-made professional molding production equipment for you.

|

|

|

| Under Cover | Anti-Collision Beam |

| Speed | V=1~5 mm/s | V=10 mm/s | V=20 mm/s |

| Accurate | ±0.05 mm | ±0.10 mm | ±0.20 mm |

| Type | Unit | 2000T | 2500T | 3000T | 4000T | 5000T | 6000T | |

| Force | KN | 20000 | 25000 | 30000 | 40000 | 50000 | 60000 | |

| Max. Fluid pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | |

| Max. opening | mm | 2400 | 2400 | 2600 | 3500 | 3500 | 3500 | |

| Max. stroke | Mm | 2000 | 2000 | 2200 | 3000 | 3000 | 3000 | |

| Working table size | L-R | mm | 3000 | 3500 | 3500 | 4000 | 4200 | 4500 |

| F-B | Mm | 2000 | 2500 | 2500 | 3000 | 3200 | 3200 | |

| Speed | Fast down | mm | 500 | 500 | 500 | 500 | 500 | 500 |

| Pressing | mm | 1-40 | 1-40 | 1-40 | 1-40 | 1-40 | 1-40 | |

| Slow down | mm | 1-40 | 1-40 | 1-40 | 1-40 | 1-40 | 1-40 | |

| Fast down | mm | 400 | 400 | 400 | 400 | 400 | 400 | |

| Power | mm | 203 | 203 | 284 | 284 | 365 | 365 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom GMT Servo Composite Hydraulic Press Manufacturers and GMT Servo Composite Hydraulic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

In the industrial manufacturing sector, precision, efficiency, and energy saving are always core objectives pursued by enterprises. With the rapid development of composite materials, automotive parts, and high-end aerospace component production, traditional hydraulic molding presses are gradually facing challenges in efficiency, precision, and intelligence. The GMT Servo Molding Press, with its superior performance, is becoming a focus of industry attention. So, why does the GMT servo molding press stand out among numerous devices?

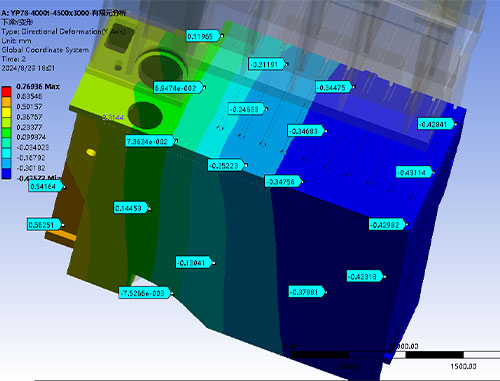

Traditional hydraulic molding presses rely on mechanical hydraulic systems for drive. While highly reliable, they often suffer from insufficient control precision in complex processes. The GMT servo molding press achieves high-precision control of force, displacement, and speed through a deep integration of a high-performance servo motor and hydraulic system.

In actual production, this means that material flow and mold closing speed can be strictly controlled in every molding process, significantly reducing scrap rates and improving product consistency. For automotive interior parts, rail transit components, and aerospace composite structural parts, the improved precision directly leads to cost control and quality assurance.

Wuxi PengdaHZ Intelligent Equipment Co., Ltd., a professional hydraulic press manufacturer with over 20 years of experience in the industry, focuses on innovation in molding press technology, continuously optimizing the response speed and stability of its servo control system to ensure that every GMT servo molding press performs at its maximum capacity in high-precision production scenarios.

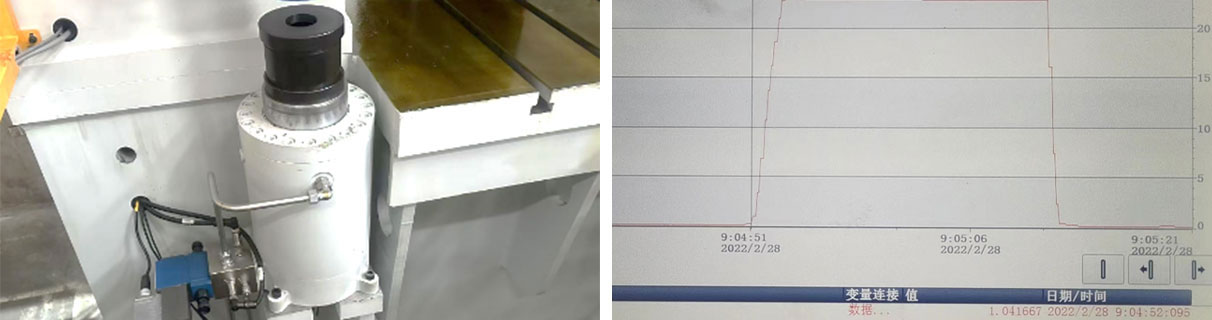

Energy consumption has always been a key concern for large industrial equipment. Compared to traditional hydraulic molding presses, the GMT servo molding press excels in energy saving. This equipment uses a servo motor to drive the hydraulic pump, intelligently adjusting power output according to the actual production load, avoiding unnecessary energy loss.

During long-term continuous production, energy consumption can be significantly reduced compared to traditional equipment. This not only reduces production costs but also meets the requirements of modern manufacturing for green production.

At Wuxi PengdaHZ Intelligent Equipment Co., Ltd., we integrate energy-saving concepts throughout the entire equipment design process, from servo systems to hydraulic circuit optimization. Every GMT servo molding press embodies a dual pursuit of efficiency and environmental protection.

Modern manufacturing is developing towards digitalization and intelligence. The GMT servo molding press's control system not only supports precise parameter adjustment but also seamlessly integrates with the factory's MES system, enabling real-time monitoring and intelligent optimization of production data.

Operators can easily set molding programs, monitor pressure curves and displacement changes via a touchscreen. The system can also automatically adjust pressure and speed according to production needs, achieving highly efficient automated production. This intelligent control significantly shortens equipment commissioning time and improves production flexibility and response speed.

As an experienced hydraulic press manufacturer, Wuxi PengdaHZ Intelligent Equipment Co., Ltd. maintains a leading position in intelligent control R&D. We not only provide mature and stable hardware solutions but also customize intelligent control software suitable for various production processes, meeting the needs of high-precision industries from automotive and rail transportation to aerospace.

GMT servo molding presses, with their high precision, high stability, and energy-saving performance, are widely used in automotive parts, rail transportation components, aerospace composite materials, and building decoration materials. In automotive interior parts production, it enables precise molding of complex materials; in the rail transportation sector, it ensures dimensional consistency of critical structural components; and in aerospace composite material manufacturing, it meets stringent precision and reliability requirements.

Wuxi PengdaHZ Intelligent Equipment Co., Ltd., leveraging over 20 years of experience in hydraulic press R&D, focuses on end-to-end technological innovation in molding machines. Each GMT servo molding machine undergoes rigorous testing and optimization to ensure stable operation in various production environments, providing customers with sustainable and efficient production solutions.

Choosing a high-quality GMT servo molding machine means choosing higher production efficiency, lower energy consumption, and superior product quality. Wuxi PengdaHZ Intelligent Equipment Co., Ltd. has cultivated expertise in this field for many years. By focusing on the R&D, production, and technological innovation of hydraulic molding machines, our equipment is not only reliable but also flexible and customizable, meeting the diverse needs of different industries.

Whether in the automotive, rail transportation, aerospace, or high-end building materials manufacturing industries, our GMT servo molding machines provide efficient, intelligent, and stable production support, enabling companies to maintain a leading edge in the fierce market competition.

As industrial manufacturing evolves towards higher precision, lower energy consumption, and greater intelligence, GMT servo molding machines are becoming indispensable equipment in modern manufacturing. Their precise control capabilities, significant energy-saving advantages, and intelligent management functions bring a qualitative improvement to production across various industries. Choosing GMT servo molding machines from Wuxi PengdaHZ Intelligent Equipment Co., Ltd. means choosing a technologically advanced, reliable, and energy-efficient production partner.

In the future wave of industrial intelligence, GMT servo molding machines will continue to drive manufacturing upgrades with their unique advantages, creating greater value for enterprises.