2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

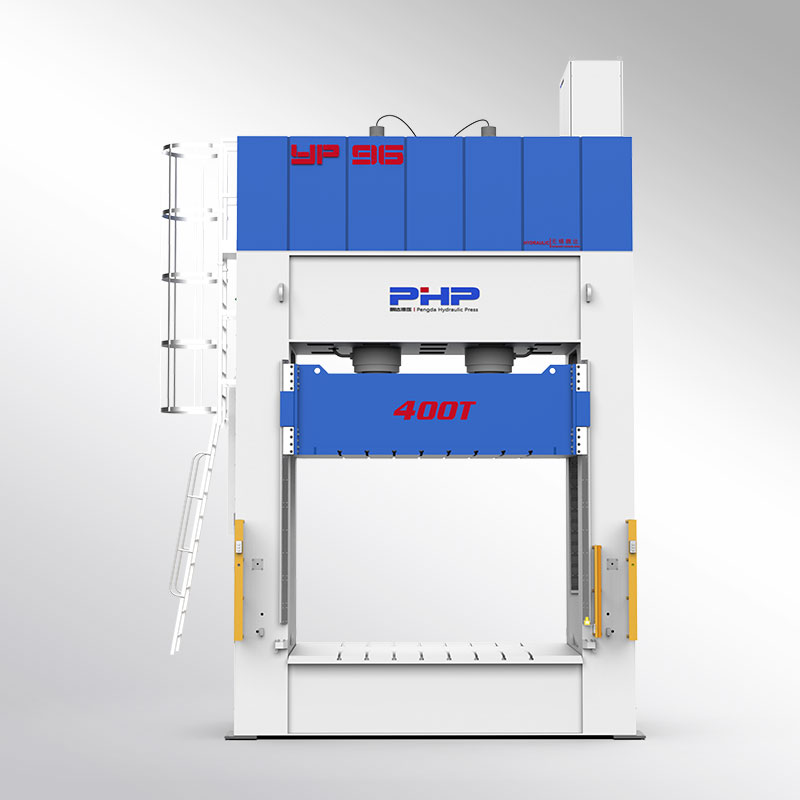

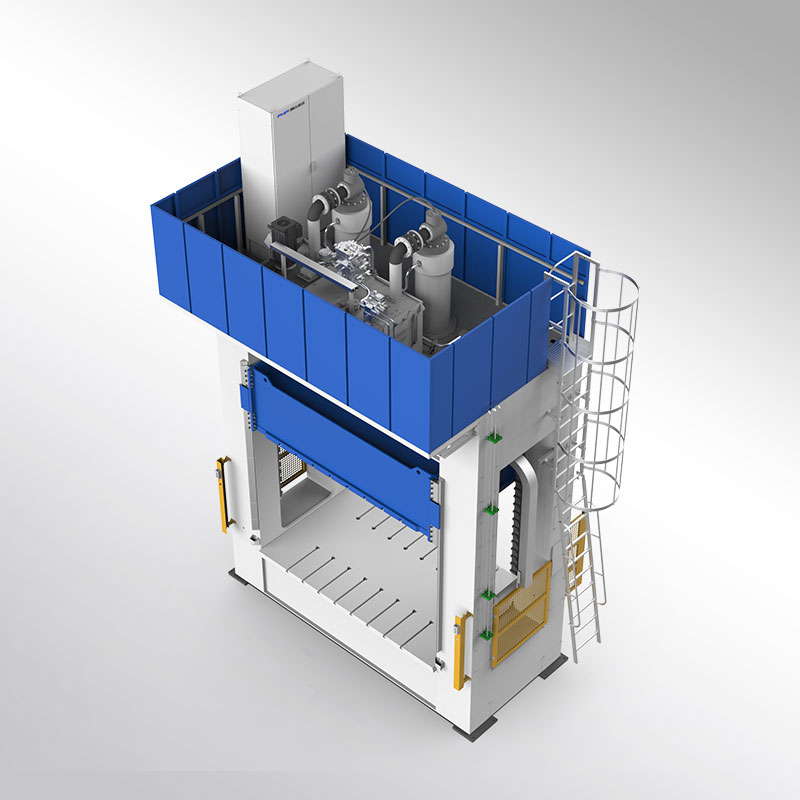

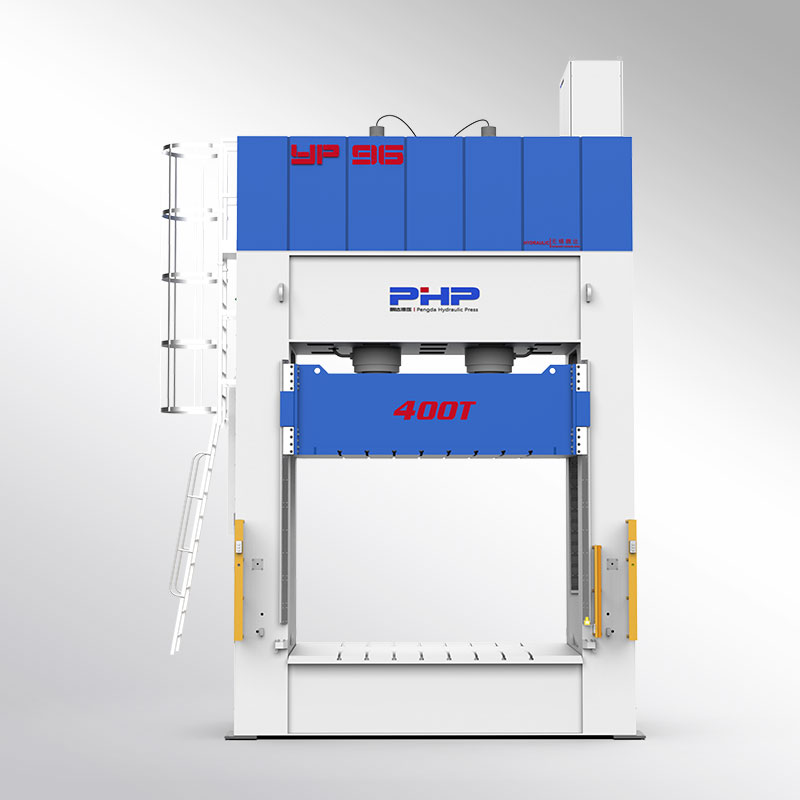

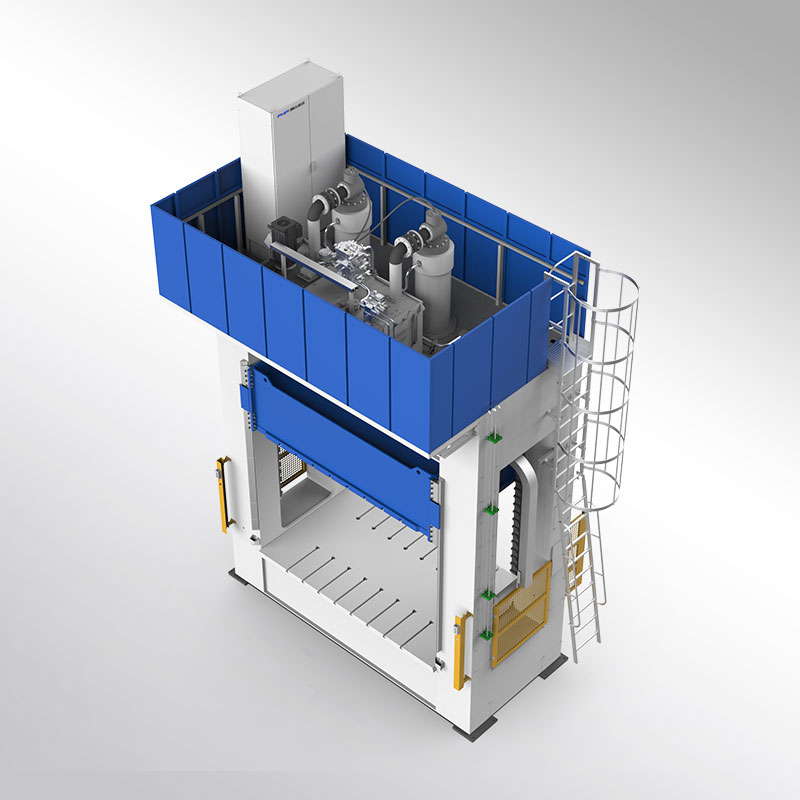

The PHP (Pengda Hydraulic Press) Wheel Cover Shell Hydraulic Press is specifically designed for the efficient production of automotive wheel cover shells. The press adopts advanced hydraulic technology and a servo-controlled frame structure, ensuring high precision, strong stability, and long-term reliability to meet the automotive industry’s demands for high-quality and high-efficiency production.

Servo Auto Trim Hydraulic Press for Wheel Cover

High Precision. High Stability. High Value

The Wheel Cover Shell Hydraulic Press manufactured by Pengda Hydraulic Press provides a precise, efficient, and reliable solution for automotive wheel cover shell production. With advanced hydraulic control, servo technology, and optimized design, it helps manufacturers enhance product quality and improve production efficiency, making it the ideal choice for wheel cover shell manufacturing.

The PHP Servo Wheel Cover Shell Hydraulic Press Is Designed And Manufactured With A Range Of Significant Advantages, Making Production More Efficient And Reliable:

● High precision: The servo-controlled frame structure ensures accurate forming dimensions and high repeatability.

● Stable and reliable: Optimized structural design minimizes vibration and maintains stable operation even under heavy loads.

● High efficiency: The integration of hydraulic and servo systems enables fast forming cycles and high productivity.

● Low failure rate: Robust construction and reliable core components reduce downtime and maintenance requirements.

|

|

|

| Pressure | 400T | |

| Max. Opening | 2100 | |

| Stroke | 1500 | |

| Working table size | L-R | 3000 |

| F-B | 2000 | |

| The height from working table to the floor | 700 | |

| Slider speed | Fast down | 300 |

| Slow down | 10-30 | |

| Return | 200 | |

| Power | 44 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom Wheel Cover Shell Hydraulic Press Manufacturers and Wheel Cover Shell Hydraulic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

As a professional manufacturer of non-metallic hydraulic presses, PHP (Pengda Hydraulic Press), founded in 2004, brings nearly two decades of specialization to the automotive components industry. Our commitment to green industry principles and technological innovation drives the development of energy-saving hydraulic presses that serve diverse sectors worldwide.

The following table outlines key parameters for our Wheel Cover Shell Hydraulic Presses, though exact specifications may vary based on custom requirements:

| Parameter | Specification/Description |

| Core Terminology | Wheel Cover Shell Hydraulic Press |

| Equipment Type | Servo Auto-Trim Hydraulic Press |

| Nominal Pressure | 200 - 2000 tons (Customizable based on wheel cover size) |

| Table Size | Customized to client needs (e.g., 1200mm x 1200mm to 2500mm x 2500mm) |

| Slide Stroke | 500 - 1000 mm (Adjustable) |

| Daylight Height | 1000 - 1500 mm (Adjustable) |

| Control System | Full Servo CNC System, PLC + Touch Screen HMI |

| Automation Options | Integration with robotic arms, automatic feeders, conveyors for complete production lines |

This application directly aligns with PHP's core product line of Servo Interior Parts Hydraulic Presses, designed for automotive interior processes including molding, compounding, and punching. Our presses enable manufacturers to address the industry challenge of producing wheel covers that meet stringent lightweight and structural integrity requirements.

This highlights PHP's corporate DNA – commitment to green industry principles and technological innovation. Our servo-hydraulic systems consume energy only when needed, unlike conventional hydraulic systems, leading to dramatic reductions in operating costs and environmental impact.

PHP is committed to providing fully automated production lines and integrated services. This capability extends beyond single machines to complete solutions encompassing automatic loading, pressing, and unloading – a key factor in earning strong customer recognition.

This title strategically connects to PHP's other core expertise – Servo Composite Hydraulic Presses. As the automotive industry, especially in electric vehicles, increasingly adopts lightweight composites, PHP's experience with materials like SMC, LFT-D, and carbon fiber positions us to offer cutting-edge solutions for next-generation wheel covers.

This perspective summarizes PHP's nearly twenty-year philosophy of specialization. It emphasizes how our focus on mechanical design excellence, standardized key systems, and responsive service delivers the stability and reliability essential for high-volume wheel cover production, minimizing downtime and ensuring consistent quality.

The Wheel Cover Shell Hydraulic Press represents a critical intersection of precision, efficiency, and innovation in automotive component manufacturing. PHP (Pengda Hydraulic Press) leverages its deep expertise in both servo-controlled hydraulic technology and non-metallic molding processes to provide comprehensive solutions. By focusing on energy efficiency, automation integration, and proven reliability, PHP helps manufacturers navigate industry challenges and achieve new levels of productivity and product quality. For specific application requirements and technical consultations, we welcome direct inquiries to explore optimal solutions for your production needs.