2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

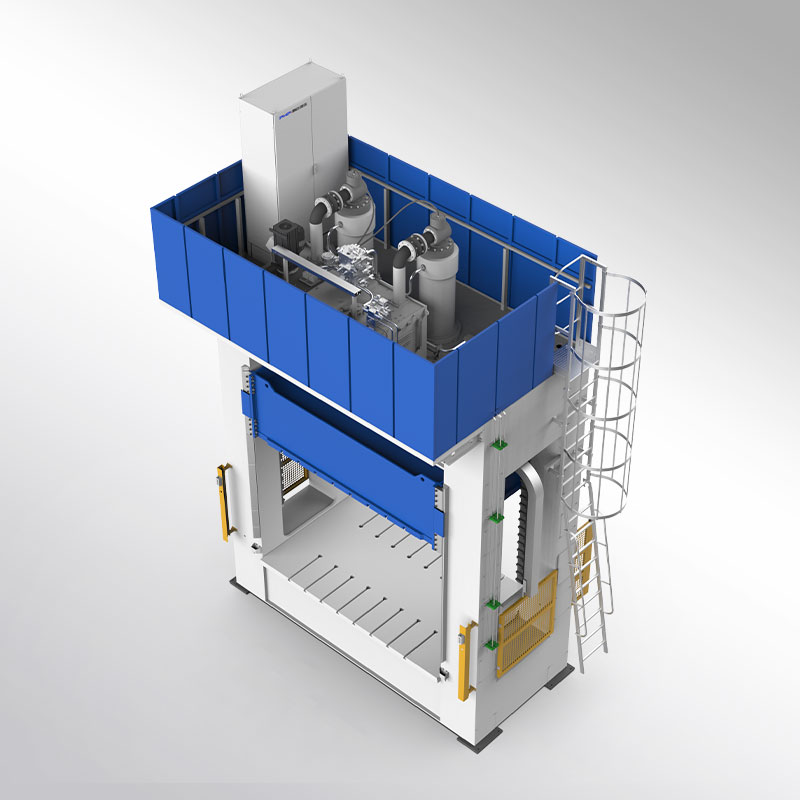

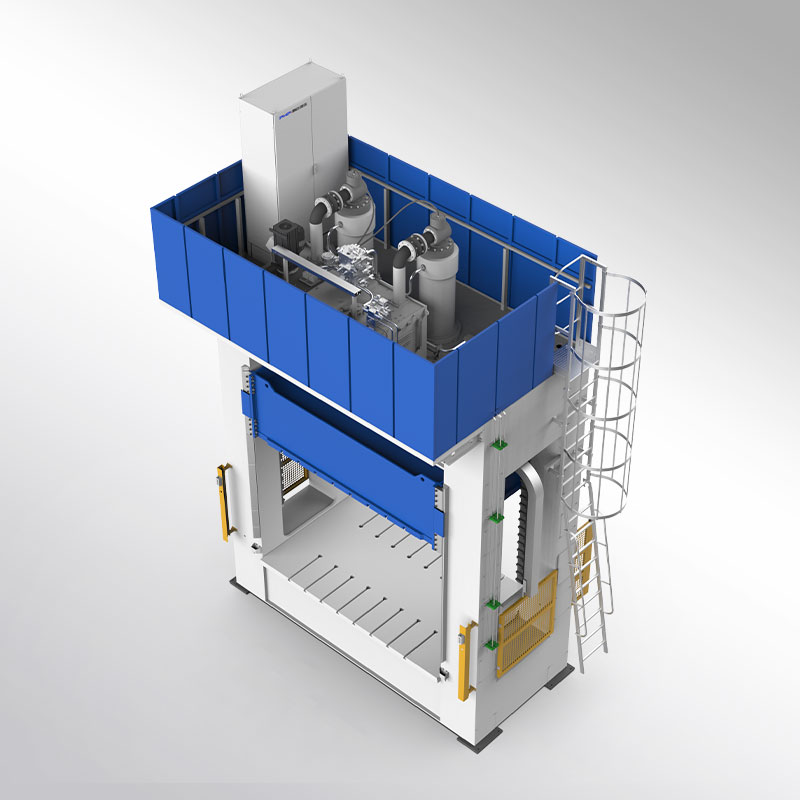

The PHP (Pengda Hydraulic Press) 400-ton hydraulic press is specifically designed for the forming of hemp felt automotive seat back panels, providing stable and reliable performance for high-volume automotive production. The press can be easily integrated with automated production lines, enabling an efficient production workflow with simple and user-friendly operation.

Servo Auto Trim Hydraulic Press for Flax felt Seat Back

Precision · Safety · Efficiency

PHP (Pengda Hydraulic Press) is dedicated to the design and manufacturing of hemp felt automotive seat back presses. Each machine is built to ensure high stability, precision, and operational safety, and complies with international safety and quality standards such as CE and UL.

With PHP(Pengda Hydraulic Press) hydraulic presses, manufacturers benefit from consistent forming quality, efficient production, and long-term reliable operation, making them a trusted choice for automotive seat back panel production.

| Pressure | 400T | 600T | |

| Max. Opening | 1600 | 1600 | |

| Stroke | 1200 | 1200 | |

| Working table size | L-R | 3000 | 3200 |

| F-B | 1800 | 2000 | |

| The height from working table to the floor | 700 | 700 | |

| Slider speed | Fast down | 300 | 300 |

| Slow down | 10-30 | 10-30 | |

| Return | 200 | 200 | |

| Power | 37 | 56 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom Hemp Felt Seat Back Hydraulic Press Manufacturers and Hemp Felt Seat Back Hydraulic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

Hemp felt seat backs are increasingly used in automotive and furniture industries due to their lightweight, durable, and environmentally friendly properties. The Hemp Felt Seat Back Hydraulic Press plays a crucial role in manufacturing high-quality seat backs efficiently.

The Hemp Felt Seat Back Hydraulic Press is an essential tool for manufacturers aiming to improve production efficiency and product quality while maintaining sustainability standards. By combining precise hydraulic pressing with high-quality hemp felt materials, companies can produce durable, comfortable, and environmentally responsible seat backs at scale.

The manufacturing of seat backs, especially using hemp felt, has evolved significantly with the introduction of hydraulic press technology. Compared with traditional pressing methods, the Hemp Felt Seat Back Hydraulic Press offers enhanced efficiency, precision, and product quality. PHP(Pengda Hydraulic Press), founded in 2004, is a leading manufacturer of non-metallic hydraulic presses, specializing in energy-saving and technologically innovative solutions.

| Feature | Hemp Felt Seat Back Hydraulic Press | Traditional Pressing Methods |

|---|---|---|

| Pressure Consistency | High | Medium |

| Production Efficiency | High | Low |

| Material Waste | Low | High |

| Automation Compatibility | High | Low |

| Product Quality | High | Medium |

| Safety | Advanced | Basic |

The Hemp Felt Seat Back Hydraulic Press clearly outperforms traditional pressing methods in terms of efficiency, product quality, energy savings, and automation potential. PHP(Pengda Hydraulic Press) focuses on designing and manufacturing these presses with stability, reliability, and industry-leading standards, making them a preferred choice for modern non-metallic seat back production.