2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

BMC (Bulk Molding Compound) is a thermosetting composite made of unsaturated polyester resin, chopped glass fibers, fillers, and additives. It features excellent strength, dimensional stability, heat resistance, and electrical insulation. With compression or injection molding, BMC ensures short cycle times and efficient material use. It is widely applied in automotive parts, electrical components, and appliances. The BMC servo hydraulic press enables precise control and energy-saving operation, ensuring stable molding quality and higher productivity.

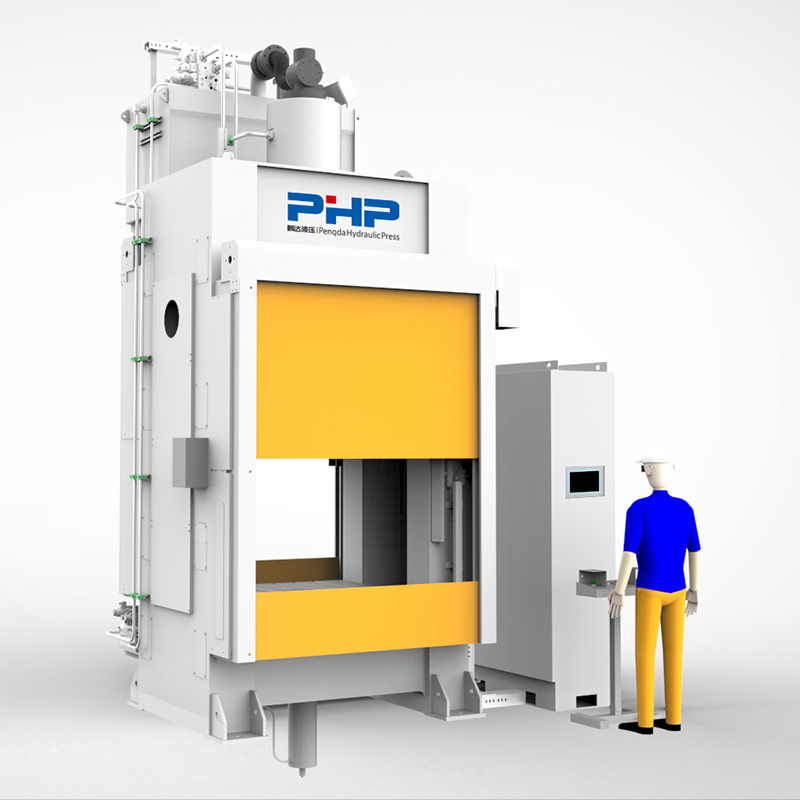

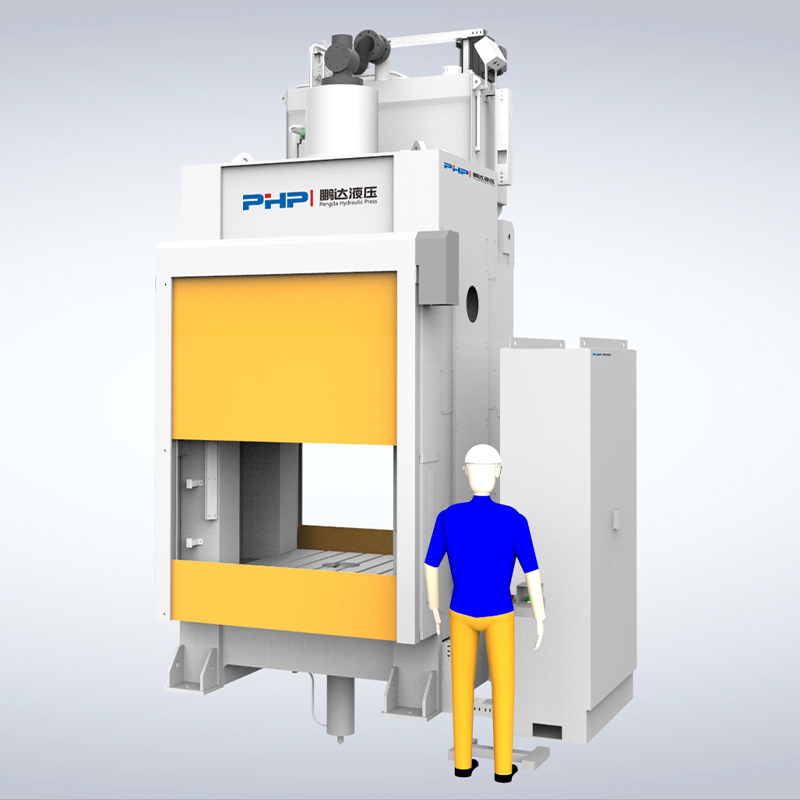

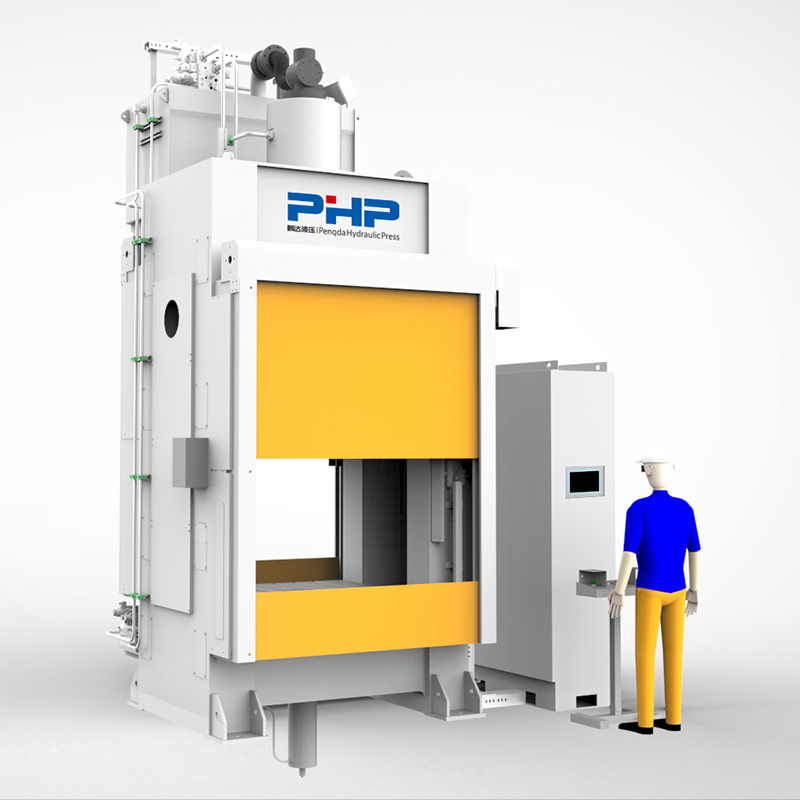

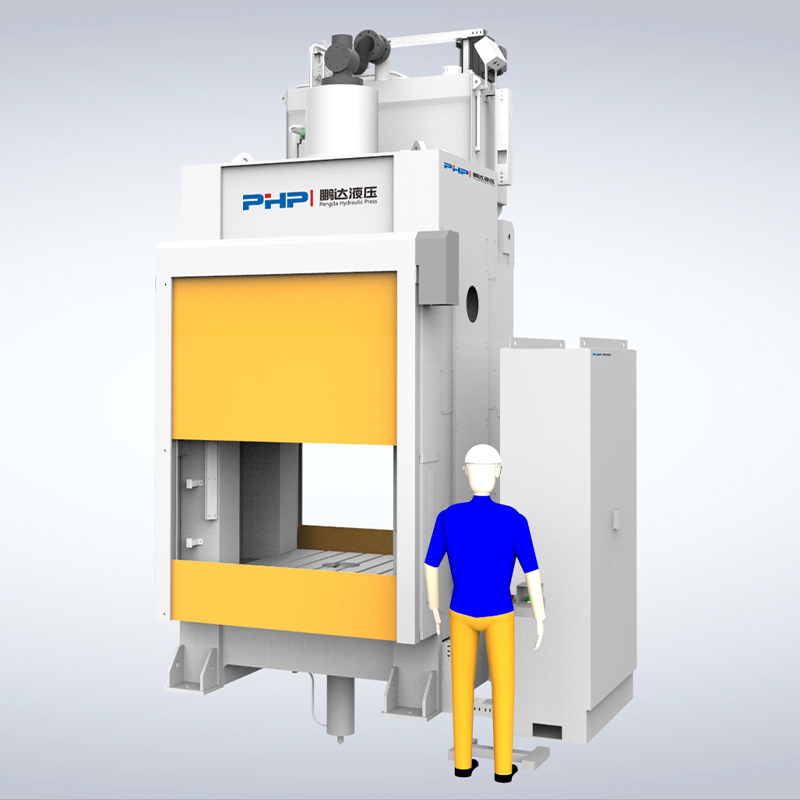

BMC Servo Composite Hydraulic Press

Professional / Reliable / Safe / Efficient

Bulk molding compound (BMC) is a glass fiber reinforced thermosetting polymer material with lightweight, high strength, high hardness, high corrosion resistance, and other characteristics. It is widely used in electronics, military, aerospace, automotive, and other fields.

Pengda BMC press is fast, stable, energy-saving, and safe. Tailor-made for customers or using Pengda's standard models, you will have a different harvest.

| Type | Unit | 100T | 200T | 315T | 400T | 500T | |

| Force | kN | 1000 | 2000 | 3150 | 4000 | 5000 | |

| Max. pressure | Mpa | 26.3 | 24.9 | 25.1 | 25.2 | 25.5 | |

| Max. opening | mm | 800 | 1100 | 1250 | 1400 | 1500 | |

| Max. stroke | mm | 500 | 700 | 800 | 800 | 900 | |

| Working table size | L-R | mm | 800 | 1000 | 1250 | 1250 | 1400 |

| F-B | mm | 600 | 900 | 1200 | 1200 | 1400 | |

| Speed | Fast down | mm | 150 | 150 | 150 | 150 | 150 |

| Holding pressure | mm | 5-20 | 5-20 | 5-15 | 5-15 | 5-10 | |

| Slow return | mm | 30-50 | 30-50 | 30-50 | 30-50 | 30-50 | |

| Fast return | mm | 150 | 150 | 150 | 150 | 150 | |

| Working table height to the floor | mm | 800 | 800 | 900 | 900 | 900 | |

| Power | mm | ≈9 | ≈9 | ≈12 | ≈12 | ≈12 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom BMC Servo Molding Press Manufacturers and BMC Servo Molding Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

BMC (Bulk Molding Compound) servo molding presses are advanced machines designed to optimize the thermoset molding process. By integrating servo-driven technology, these presses offer precise control, energy efficiency, and faster cycle times, making them ideal for high-volume production in industries such as automotive, electrical, and consumer goods.

Servo motors allow for highly accurate control of the molding cycle, including clamping force, injection speed, and pressure. This precision reduces defects and ensures consistent quality in thermoset products, minimizing waste and rework.

Unlike traditional hydraulic presses, BMC servo presses can achieve faster mold opening and closing speeds while maintaining accuracy. This reduces the overall cycle time, allowing more parts to be produced per hour and improving overall production efficiency.

Servo-driven systems consume energy only when motion is required, unlike conventional hydraulic systems that run continuously. This results in significant energy savings, lower operating costs, and a smaller environmental footprint.

The programmable nature of servo presses allows manufacturers to easily adjust molding parameters for different product designs without extensive downtime. This flexibility supports rapid prototyping, small-batch production, and adaptation to changing production demands.

With fewer mechanical components under continuous stress, servo presses generally require less maintenance than traditional presses. This leads to reduced downtime, longer machine life, and higher overall equipment effectiveness (OEE).

Investing in a BMC servo molding press can significantly improve production efficiency in thermoset molding by enhancing precision, reducing cycle times, saving energy, and increasing process flexibility. Manufacturers seeking higher output and consistent quality will benefit from adopting this advanced technology.

BMC servo molding presses represent a significant advancement over traditional hydraulic presses in the thermoset and composite molding industry. By integrating servo-driven technology, these presses provide precise control, faster cycle times, and energy efficiency, which are critical for high-quality production in automotive, aerospace, and other advanced manufacturing sectors.

Servo presses use electronic control systems to adjust clamping force, injection speed, and pressure with high accuracy. This allows for consistent product quality and reduced scrap rates. In contrast, traditional hydraulic presses rely on mechanical systems, which can result in variations in force and less precise molding outcomes.

BMC servo presses consume energy only during motion, unlike conventional hydraulic systems that operate continuously. This leads to significant energy savings, reduced operating costs, and improved sustainability. PHP(Pengda Hydraulic Press) specializes in designing energy-saving hydraulic presses, combining servo technology with optimized mechanical design to meet green industry principles.

The servo-driven system allows faster mold opening and closing without sacrificing accuracy, which shortens the overall cycle time. Traditional presses generally have slower cycles due to mechanical limitations. Faster cycles directly contribute to higher throughput and production efficiency.

Servo presses can be easily programmed for different molding processes and materials. PHP's R&D focuses on two categories of non-metallic molding presses:

Servo presses offer operational stability with less mechanical wear, leading to reduced maintenance requirements. Advanced safety systems are integrated for operator protection. Traditional hydraulic presses may require more frequent maintenance due to higher mechanical stress.

| Feature | BMC Servo Molding Press | Traditional Hydraulic Press |

|---|---|---|

| Clamping Force Control | Servo-driven, precise and programmable | Mechanical/hydraulic, less precise |

| Energy Consumption | Low, only during motion | High, continuous operation |

| Cycle Time | Short, faster mold operations | Longer, slower mechanical motion |

| Maintenance | Reduced, less mechanical wear | Frequent, higher wear on components |

| Applications | Thermoset composites, SMC, GMT, LFT-D, HP-RTM | General molding, limited composite capability |

BMC servo molding presses outperform traditional hydraulic presses in terms of precision, energy efficiency, cycle time, and flexibility. PHP(Pengda Hydraulic Press) leverages these technologies to produce stable, reliable, and energy-saving non-metallic presses tailored for diverse industrial applications. Companies seeking high-quality, efficient, and sustainable molding solutions can greatly benefit from adopting servo-driven press technology.