2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

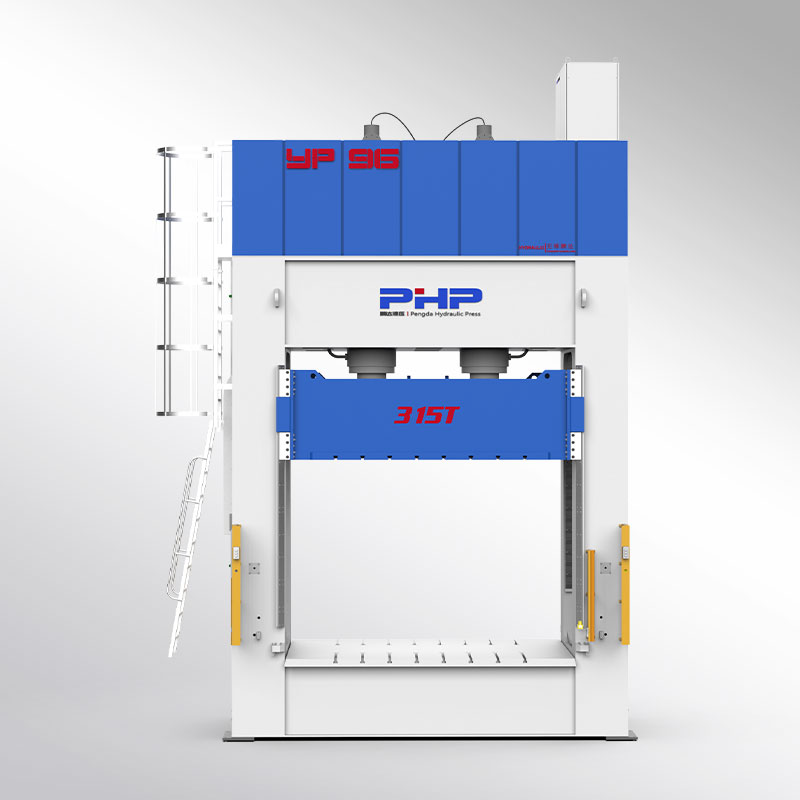

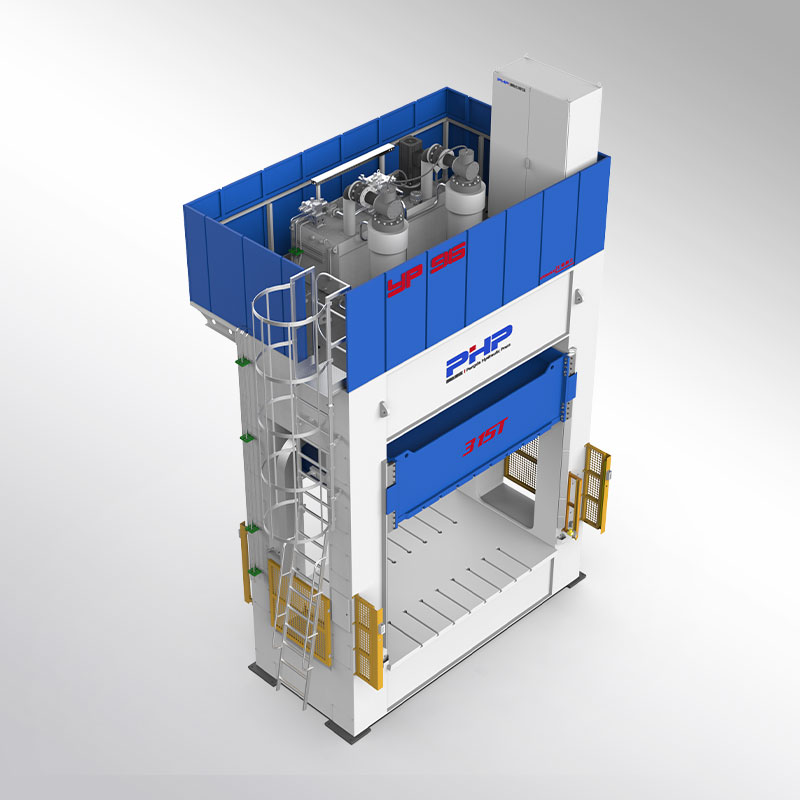

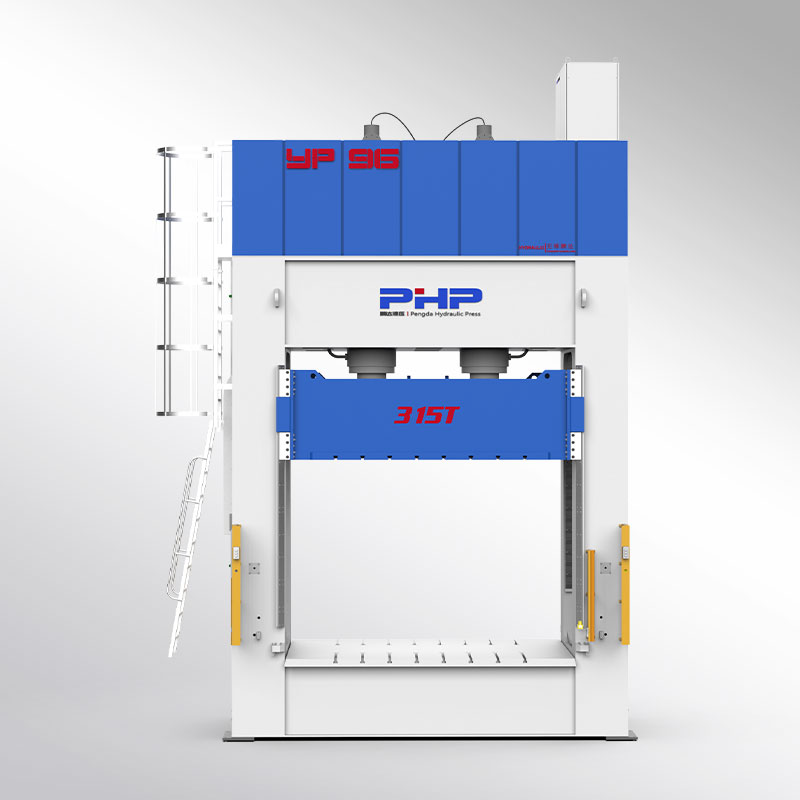

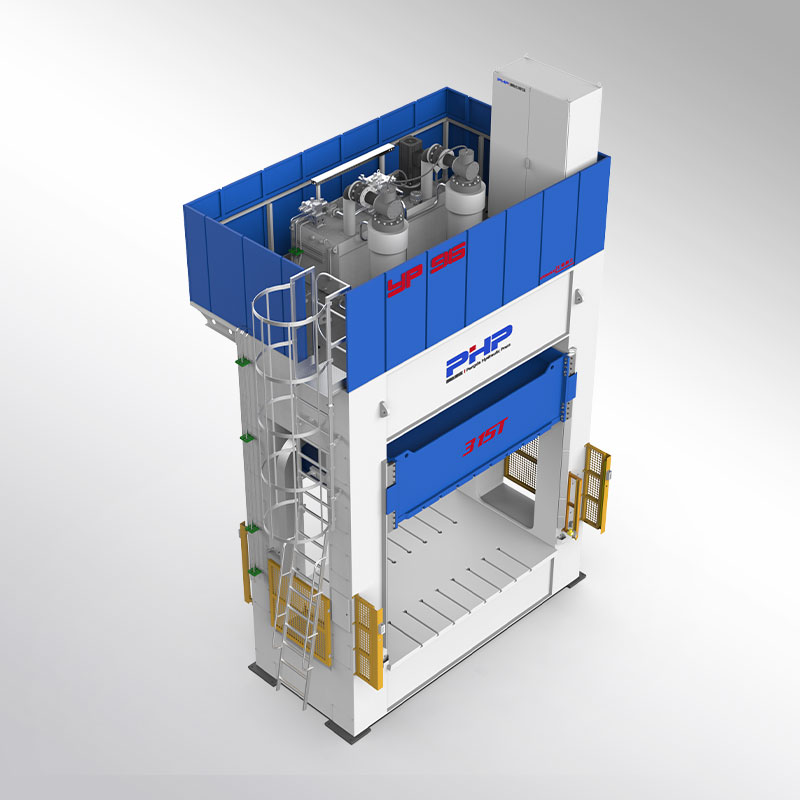

PHP(Pengda Hydraulic Press)’s automotive trunk lid hydraulic press is specially developed for the efficient forming of car trunk lids. The equipment integrates a high-performance hydraulic system with intelligent servo control technology, ensuring high forming precision while achieving stability and reliability. It provides automakers with a high-quality, low-energy consuming forming solution.

Servo Auto Trim Hydraulic Press for Trunk Cover

Smart Forming, Energy-Saving Pioneer

The PHP(Pengda Hydraulic Press) automotive trunk lid hydraulic press combines reliable performance with exceptional forming precision, helping manufacturers achieve efficient and stable production processes. It not only ensures product quality but also assists companies in reducing operational costs and enhancing production line flexibility, making it a trusted core equipment for trunk lid manufacturing.

● With its outstanding structural design and intelligent control system, the automotive trunk lid hydraulic press excels in efficiency, precision, and reliability.

● Precision Forming: The combination of servo control and rigid frame structure ensures each trunk lid achieves accurate dimensions and excellent repeatability.

● Stability and Reliability: Optimized structural design and robust frame allow the machine to handle high loads and long production cycles, running smoothly and worry-free.

● High Efficiency: The hydraulic and servo systems work in synergy to achieve fast forming and high output.

● Energy Saving & Environmentally Friendly: Advanced servo technology significantly reduces energy consumption while improving overall production efficiency.

Trunk Covers usually require high flatness and rigidity, and their large dimensions make them prone to warping or local stress concentration during forming. The PHP(Pengda Hydraulic Press) hydraulic press overcomes these challenges through a frame-servo structure and optimized pressure distribution design, ensuring that every product meets strict quality standards.

With The Following Features, The Php Automotive Carpet Hydraulic Press Delivers Efficient, Precise, And Safe Forming Operations:

● Energy-efficient servo drive: Reduces energy consumption and enables sustainable production.

● Optimized structure, stable operation: Maintains reliable performance during long-term continuous production.

● High-precision forming: Ensures product consistency and minimizes defects.

● Safety design: Fully compliant with safety standards for secure operation.

|

|

|

| Pressure | 200T | 315T | |

| Max. Opening | 1200 | 2400 | |

| Stroke | 1100 | 1800 | |

| Working table size | L-R | 2000 | 3000 |

| F-B | 1500 | 2000 | |

| The height from working table to the floor | 700 | 700 | |

| Slider speed | Fast down | 300 | 300 |

| Slow down | 5-15 | 10-30 | |

| Return | 150 | 200 | |

| Power | 18 | 44 | |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom Trunk Lid Hydraulic Press Manufacturers and Trunk Lid Hydraulic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

In the rapidly evolving automotive industry, the production of trunk lids presents unique challenges that demand specialized manufacturing solutions. PHP (Pengda Hydraulic Press), with nearly two decades of expertise in non-metallic hydraulic presses, offers innovative approaches through its specialized Trunk Lid Hydraulic Press technology. Here are five key insights that demonstrate how modern hydraulic press technology is transforming trunk lid manufacturing.

Modern automotive design demands trunk lids that combine lightweight construction with structural integrity. PHP's Servo Composite Hydraulic Presses are specifically engineered to meet these challenging requirements through advanced material processing capabilities.

Founded in 2004 with a firm commitment to green industry principles and technological innovation, PHP has pioneered energy-efficient solutions that deliver both environmental sustainability and significant cost advantages in high-volume production environments.

PHP's application of Servo Interior Parts Hydraulic Presses technology enables integrated "molding-compounding-punching" processes for trunk lid manufacturing. This comprehensive approach addresses multiple production challenges in a single operation.

As composite materials gain prominence in trunk lid applications, traditional metal stamping equipment faces limitations. PHP's nearly twenty years of specialization in non-metallic molding presses provides unique advantages for modern manufacturing requirements.

PHP's twenty-year specialization philosophy centers on delivering stable and reliable non-metallic presses that address the fundamental concerns of automotive manufacturers in high-volume production environments.

The evolution of trunk lid manufacturing requires specialized expertise and reliable technology partnerships. PHP (Pengda Hydraulic Press) combines nearly twenty years of focused experience in non-metallic press technology with an unwavering commitment to innovation and customer success. By addressing the specific challenges of trunk lid production—from lightweight composite materials and energy efficiency to precision control and automation integration—PHP enables manufacturers to meet the demanding quality standards of the global automotive industry while maintaining competitive production costs.

Through continuous dedication to mechanical design excellence, standardized key systems, and responsive global service, PHP maintains its position as a trusted partner for automotive manufacturers seeking to optimize their trunk lid production capabilities and achieve zero-defect manufacturing targets in an increasingly competitive marketplace.