Content

- 1 I. Why Is the CE Standard Particularly Important for Composite Hydraulic Presses?

- 2 II. Fundamental Differences in Design Philosophy

- 3 III. Three Core Safety Systems of CE-Compliant Hydraulic Presses

- 4 IV. Technical Documentation and Responsibility System

- 5 V. Conclusion: CE-Compliant Hydraulic Presses as a System Engineering Solution

I. Why Is the CE Standard Particularly Important for Composite Hydraulic Presses?

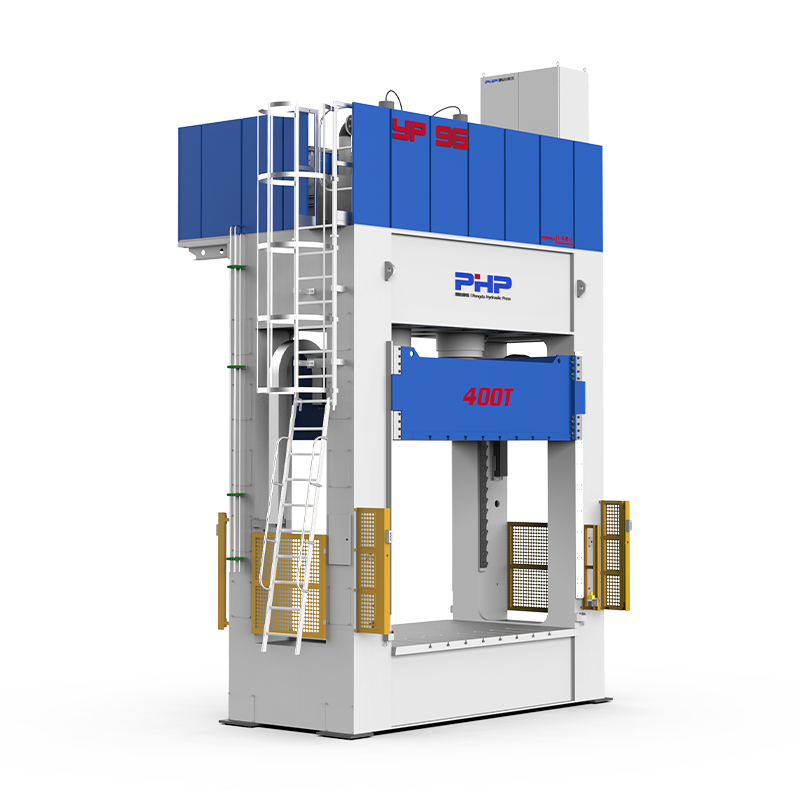

In the field of composite material forming, servo composite hydraulic presses and compression molding presses have become core equipment for compression molding processes and are typically used in combination with SMC molds to form complete SMC molding systems.

With the continuous development of composite materials toward lightweight design and structural integration, composite compression molding presses are now widely applied in the following sectors:

- Trucks and buses

- Agricultural and construction equipment

- E-mobility

- Rail transportation

- Urban furniture, among others

In these application scenarios, hydraulic presses are not only responsible for forming performance, but are also directly related to operator safety, long-term operational stability, and overall production line compliance. For this reason, an increasing number of European customers purchasing composite hydraulic presses from China for the first time tend to focus on one key question:

What are the fundamental differences between CE-compliant hydraulic presses and hydraulic presses built to domestic standards?

It should be emphasized that CE marking is not merely a certification label, but a comprehensive safety system that runs throughout the entire lifecycle of a machine—from design and manufacturing to installation and operation.

II. Fundamental Differences in Design Philosophy

Under domestic standards, hydraulic press design is typically driven by production requirements such as tonnage capacity, forming efficiency, equipment cost, and delivery time. While this approach is suitable for many local production environments, it primarily focuses on whether the machine can complete its manufacturing task.

In contrast, CE-compliant servo composite hydraulic presses must treat risk control as a core design constraint while meeting forming performance requirements. The CE framework requires systematic risk assessment to be conducted at the conceptual design stage, with structural or system-level solutions defined in advance for potential risks during operation, maintenance, commissioning, and abnormal conditions.

This “safety-by-design” philosophy means that CE compliance cannot be achieved simply by adding components after manufacturing, but must be integrated into the overall machine concept from the beginning.

III. Three Core Safety Systems of CE-Compliant Hydraulic Presses

From an implementation perspective, CE requirements for composite hydraulic presses are realized through clearly defined safety systems rather than abstract principles. These requirements are mainly concentrated in three areas: mechanical safety, hydraulic safety, and electrical safety, all of which are interrelated and indispensable.

Mechanical Safety

Under CE standards, the primary objective of mechanical safety is to reduce personnel exposure to hazardous areas through structural design itself, rather than relying solely on operating procedures or operator experience. For large composite hydraulic presses with long strokes and frequent maintenance requirements, mechanical safety is particularly critical.

CE-compliant mechanical design must systematically consider operational and maintenance scenarios, such as safe access to the machine, entry to elevated areas, and reliable securing of moving components during servicing. These requirements directly affect the overall machine layout rather than being optional add-ons.

Typical CE mechanical safety measures include:

- Safety ladders, designed to meet standards for height, inclination, and anti-slip performance

- Top maintenance platforms with guardrails, providing fall protection during servicing

- Maintenance access paths and safety distances, ensuring adequate space for personnel movement and emergency evacuation

- Slide mechanical locking systems, such as SITEMA locking devices, to securely hold the slide during maintenance and prevent unintended descent

Top maintenance platform

Top maintenance platform

Slider locking system

By comparison, domestic standard presses often rely more heavily on operational procedures rather than structural risk isolation.

Hydraulic Safety

The hydraulic system is the power core of a composite hydraulic press and also a high-risk area. Under CE standards, hydraulic systems must not only deliver performance but also incorporate clear fail-safe behavior.

This means that even in extreme conditions such as hose rupture, valve failure, or control malfunction, the system must default to a safe state to prevent uncontrolled movement or personal injury.

Typical CE hydraulic safety measures include:

- Safety valves installed on cylinders, preventing rapid slide descent in case of pressure loss

- Burst protection chains for hydraulic hoses, limiting hose whipping in case of rupture

- Redundant pressure and motion control logic, ensuring safe behavior under all conditions

Safety valve

Safety valve

Burst protection chain

In some domestic standard presses, such safety features may be simplified or omitted, relying instead on experience-based management.

Electrical Safety

Electrical safety is one of the most systematic and strictly audited aspects of CE compliance and represents one of the clearest differences compared to domestic standard machines. CE evaluation focuses not only on component quality but also on the integrity of functional safety logic.

Typical CE electrical safety configurations include:

- Safety PLCs with redundancy and self-diagnostics

- L-type safety light curtains for multi-directional protection of the molding area

- Laser scanners for dynamic area monitoring

- Emergency stop buttons, positioned according to standards

- Fully documented and verifiable safety programs, ensuring traceability and testability

Safety PLC

Safety PLC

Laser scanner

Emergency stop button

L-type safety light curtain

While control cabinets may appear similar externally, CE assessments emphasize internal logic architecture, redundancy, and consistency with technical documentation.

IV. Technical Documentation and Responsibility System

CE compliance extends beyond the physical machine to include a complete technical documentation system. These documents are not only part of delivery requirements but also essential for compliance throughout the equipment’s lifecycle.

A complete CE technical file typically includes risk assessment reports, hydraulic and electrical schematics, operation and maintenance manuals, and declarations of conformity. These documents play a critical role in audits, accident investigations, and liability determination.

V. Conclusion: CE-Compliant Hydraulic Presses as a System Engineering Solution

For servo composite hydraulic presses (including SMC presses, LFT-D presses, HP-RTM presses, GMT presses, etc.), CE compliance is not a simple post-installation addition of safety features. Instead, it represents a holistic safety philosophy, systematically integrated into the machine’s structural design, safety functions, control logic, and final application scenarios, with risk assessment at its core and guided by regulations and standards.

For customers purchasing composite hydraulic presses from China for the first time, understanding the fundamental differences between CE standards and domestic standards is a crucial step in reducing project risks and ensuring long-term, stable operation.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский