SMC hydraulic presses are integral to various industrial processes, especially in precision forming and heavy-duty manufacturing. Proper maintenance not only ensures that the machines perform efficiently but also helps in extending their lifespan, reducing operational downtime, and preventing costly repairs. In this article, we will explore how to improve the maintenance efficiency of the SMC hydraulic press and extend its operational life, providing technical insights for engineers and B2B buyers.

Content

- 1 Understanding the Basic Structure and Operating Principle of SMC Hydraulic Press

- 2 Effective Maintenance Strategies for SMC Hydraulic Press

- 3 Optimizing Maintenance for Specific Applications

- 4 Energy Saving Tips for SMC Hydraulic Press

- 5 Future Trends in SMC Hydraulic Press Maintenance

- 6 Conclusion

- 7 Frequently Asked Questions (FAQ)

- 7.1 1. How often should I perform maintenance on my SMC hydraulic press?

- 7.2 2. What are the signs that my SMC hydraulic press is experiencing issues?

- 7.3 3. How can I extend the life of my SMC hydraulic press?

- 7.4 4. How do I troubleshoot low pressure in my SMC hydraulic press?

- 7.5 5. What are the energy-saving tips for SMC hydraulic presses?

Understanding the Basic Structure and Operating Principle of SMC Hydraulic Press

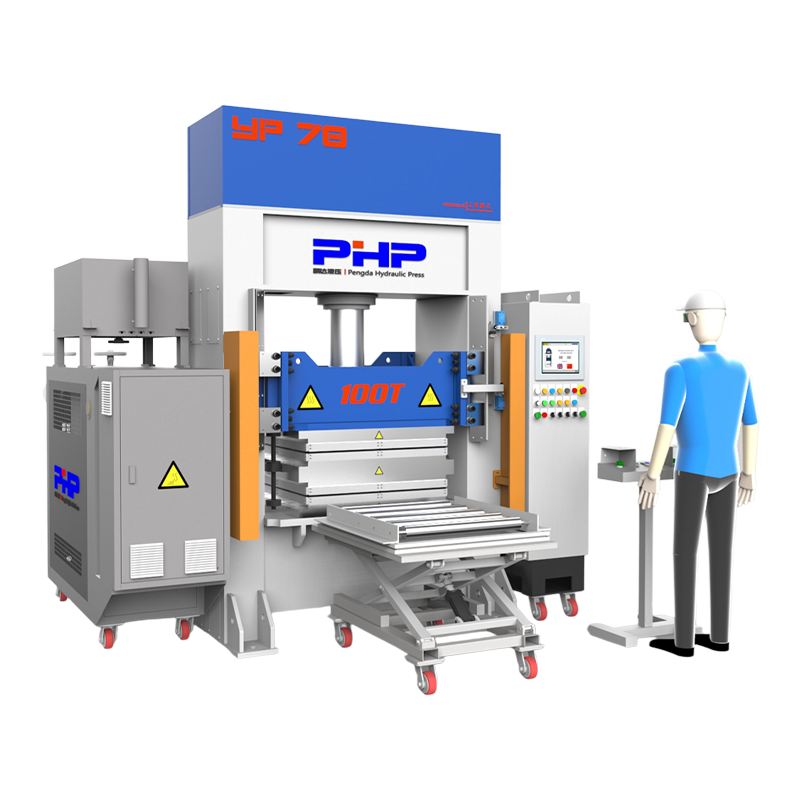

The first step in maintaining any machine is understanding its basic structure and how it operates. A SMC hydraulic press typically consists of three main components: the hydraulic system, mechanical parts, and control systems.

- Hydraulic system: This system uses fluid pressure to generate force, enabling the press to perform tasks like metal forming and shaping.

- Mechanical parts: These include the press head, slide, and ram, all critical for applying the force to the material.

- Control system: Controls the machine’s operation, ensuring precision and safety.

Working Principle of the Hydraulic Press

In basic terms, the hydraulic press uses Pascal’s law, where pressure applied to a fluid is transmitted uniformly. The system generates pressure through a hydraulic pump that moves the press head down onto the workpiece. A hydraulic oil reservoir, pump, and valves manage the pressure and force distribution across the machine.

Importance of Proper Maintenance

Failure to maintain any of these critical components can lead to reduced efficiency, breakdowns, or even catastrophic failures. Regular maintenance helps keep the SMC hydraulic press running smoothly, thus prolonging its service life and ensuring that operations remain efficient.

Effective Maintenance Strategies for SMC Hydraulic Press

Effective maintenance is key to ensuring that the SMC hydraulic press operates at peak performance. Here are several critical maintenance practices to consider:

Regular Inspection and Cleaning of the Hydraulic System

The hydraulic system requires regular checks and cleaning to prevent issues such as oil contamination, pump wear, and valve failure. Regularly replace the hydraulic fluid and clean the filters to prevent debris buildup.

Checking and Maintaining Mechanical Parts

Mechanical components such as the press head, slide, and ram should be regularly inspected for signs of wear and tear. The proper alignment of these components is crucial for ensuring optimal force application and precision. The seals, bearings, and bushings should be checked and lubricated to prevent metal fatigue and operational failures.

Maintaining Control Systems for Accuracy

The control system, including sensors and actuators, should be calibrated regularly. Improper calibration can lead to inaccurate force application, compromising the quality of the final product. Ensure that the software is up to date, and troubleshoot any faults in the electrical connections promptly.

How to Troubleshoot Common SMC Hydraulic Press Issues

Even with regular maintenance, issues might still arise. The following common problems can occur with the SMC hydraulic press:

- Low Pressure: This can be due to a damaged pump or a clogged filter.

- Oil Leaks: These often occur from faulty seals or worn-out hoses.

- Electrical Failures: Often caused by faulty wiring or control system malfunction.

In such cases, consult the troubleshooting guide for quick fixes or call in an expert. Regular checks will minimize these issues, ensuring the machine runs efficiently for longer periods.

Optimizing Maintenance for Specific Applications

Best Maintenance Practices for Small Manufacturers

Small manufacturers often face budget constraints but must still ensure the operational reliability of their SMC hydraulic press. To optimize maintenance:

- Choose a model suitable for your production volume.

- Perform preventive maintenance during off-peak hours to reduce downtime.

- Train operators to identify early signs of wear and tear.

SMC Hydraulic Press for Precision Metal Forming

In industries where precision metal forming is required, the SMC hydraulic press must be calibrated for extreme accuracy. Ensure that the system is free from contamination and that the press head operates with minimal play. Regularly adjust the ram stroke and monitor force application to ensure consistent product quality.

Energy Saving Tips for SMC Hydraulic Press

Reducing energy consumption not only helps cut operational costs but also reduces wear on the hydraulic press, leading to longer machine life. Below are some energy-saving tips:

- Use energy-efficient hydraulic fluids.

- Regularly clean and replace filters to maintain system efficiency.

- Optimize the machine’s operating cycles to prevent unnecessary energy use.

- Implement automatic shut-off systems during idle times.

Reducing Downtime and Improving Efficiency

By performing routine maintenance, you reduce the likelihood of unplanned breakdowns. Regular checks help to identify potential issues before they turn into costly repairs. The goal is to maintain high uptime, which translates into higher productivity and fewer interruptions in the manufacturing process.

Future Trends in SMC Hydraulic Press Maintenance

As hydraulic technology continues to evolve, so do the maintenance practices. With advancements in SMC hydraulic press designs, we anticipate more smart machines equipped with sensors for real-time diagnostics. These technologies will provide engineers with predictive maintenance data, helping to prevent failures before they occur.

Market Trends for SMC Hydraulic Press

The demand for SMC hydraulic presses is expected to grow as more industries look for automated and energy-efficient solutions. As such, manufacturers must continue to innovate, ensuring that their presses meet industry standards for precision and energy consumption.

Conclusion

Regular maintenance is crucial to extending the lifespan of your SMC hydraulic press and improving its operational efficiency. By understanding the components, following best practices for upkeep, and optimizing energy use, you can ensure your equipment continues to deliver reliable performance for years to come.

Frequently Asked Questions (FAQ)

1. How often should I perform maintenance on my SMC hydraulic press?

It’s recommended to perform preventive maintenance every 500-1000 operating hours, depending on the manufacturer's guidelines and the machine's usage frequency.

2. What are the signs that my SMC hydraulic press is experiencing issues?

Signs include unusual noises, inconsistent pressure, leaking oil, and faulty control system readings. Regular inspections can help identify these issues early.

3. How can I extend the life of my SMC hydraulic press?

By following a strict maintenance schedule, using high-quality hydraulic fluids, and promptly addressing minor issues, you can significantly extend the lifespan of your press.

4. How do I troubleshoot low pressure in my SMC hydraulic press?

Check for blocked filters, damaged pumps, or air in the hydraulic system. These are common causes of low pressure.

5. What are the energy-saving tips for SMC hydraulic presses?

Use energy-efficient hydraulic fluids, optimize machine cycles, and implement automated shut-off systems to reduce energy consumption.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский