2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

LFT-D molding process (Long-fiber Reinforce Thermoplastic Direct) is a new Long Fiber reinforced thermoplastic composite technology, which is a process technology for the direct online production of long fiber reinforced thermoplastic composite products.

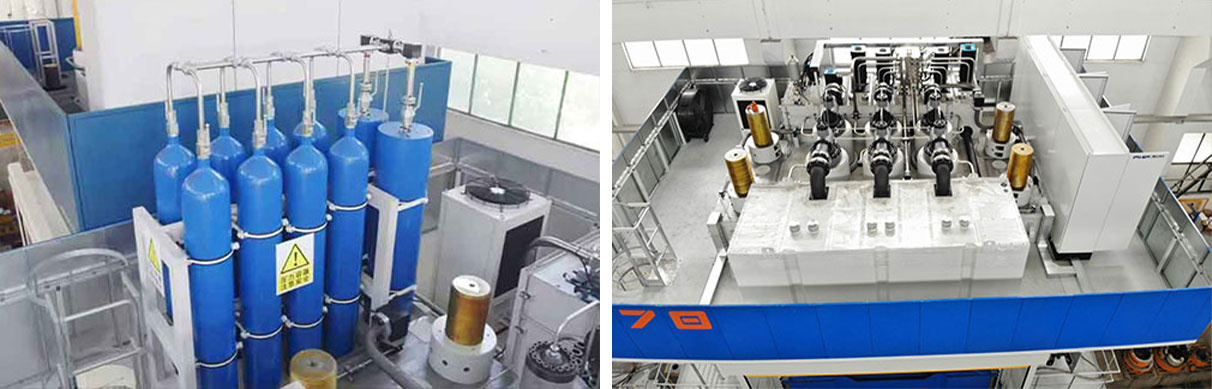

The equipment adopts high pressure accumulator system and servo oil-electric system to achieve rapid pressure building and rapid pressing functions, which brings more possibilities for LFT-D molding technology.

LFT-D Servo Composite Hydraulic Press

Thermoplastic Composite Molding Process

The LFT-D (Long Fiber Thermoplastic - Direct) press is a high-performance machine designed specifically for the direct processing of long fiber-reinforced thermoplastics. It integrates the compounding of glass or carbon fibers with thermoplastic resins (such as PP or PA) and extrudes the mixture directly into the mold for compression molding.

Compared to traditional injection molding or sheet compression techniques, the LFT-D process offers significant advantages in terms of part strength, impact resistance, lightweighting, and cost efficiency. It is widely used in applications requiring high structural performance, such as automotive bumpers, underbody shields, battery trays, and seat components.

Continuous innovation and research and development, PHP(Pengda Hydraulic Press) is committed to the development of LFT-D molding process.

|

|

|

| Car bottom guard | Building templates | 2 |

| Speed | V=1~5mm/s | V=10mm/s | V=20mm/s |

| Accurate | ±0.05 mm | ±0.10 mm | ±0.20 mm |

Fast Setting High Pressure

| Type | Unit | 2000T | 2500T | 3000T | 4000T | 5000T | 6000T | |

| Max. fluid pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | |

| Max. Opening | mm | 2400 | 2400 | 2600 | 3500 | 3500 | 3500 | |

| Max. Stroke | Mm | 2000 | 2000 | 2200 | 3000 | 3000 | 3000 | |

| Working table size | L-R | mm | 3000 | 3500 | 3500 | 4000 | 4200 | 4500 |

| F-B | Mm | 2000 | 2500 | 2500 | 3000 | 3200 | 3200 | |

| Speed | Fast down | mm | 800 | 800 | 800 | 800 | 800 | 800 |

| Pressing | mm | 1-80 | 1-80 | 1-80 | 1-80 | 1-80 | 1-80 | |

| Slow return | mm | 1-80 | 1-80 | 1-80 | 1-80 | 1-80 | 1-80 | |

| Fast return | mm | 800 | 800 | 800 | 800 | 800 | 800 | |

| Leveling force | Ton | 200 | 200 | 400 | 400 | 800 | 800 | |

| Leveling speed | V=1~5mm/s | mm | ±0.05 | |||||

| V=10mm/s | mm | ±0.10 | ||||||

| V=20mm/s | mm | ±0.20 | ||||||

| Power | mm | 272 | 272 | 353 | 353 | 390 | 390 | |

Four-Leveling System

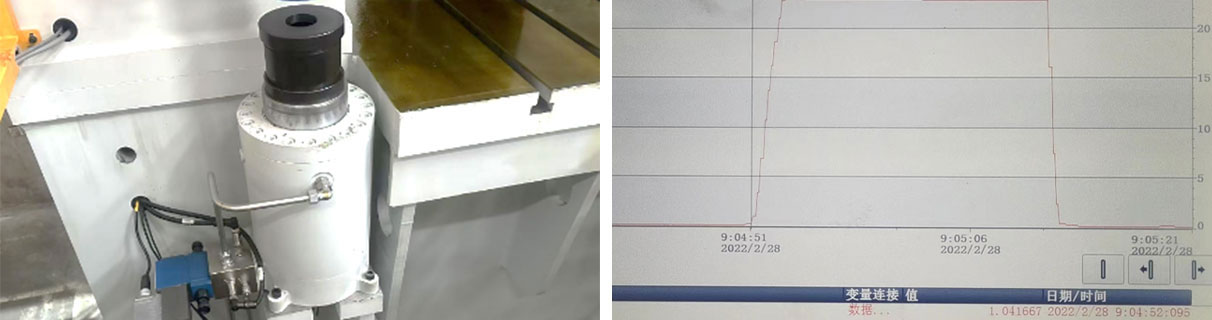

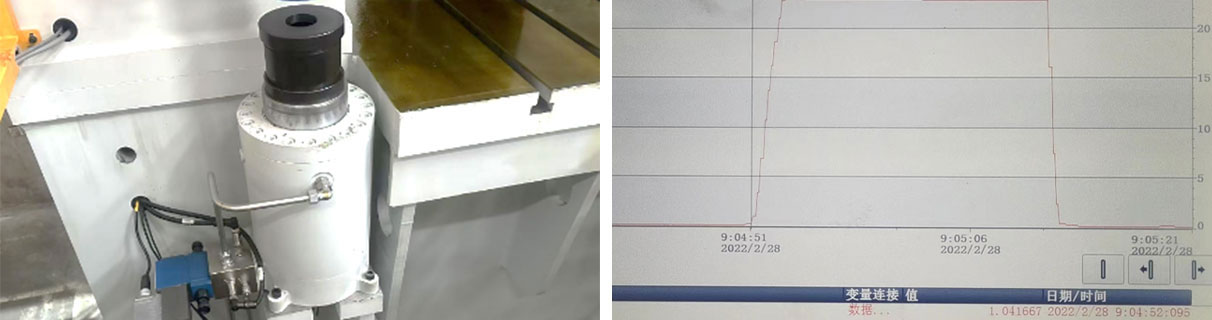

● Siemens' high precision control system.

● High-frequency response servo valve.

● Shows the curve of pressure and displacement.

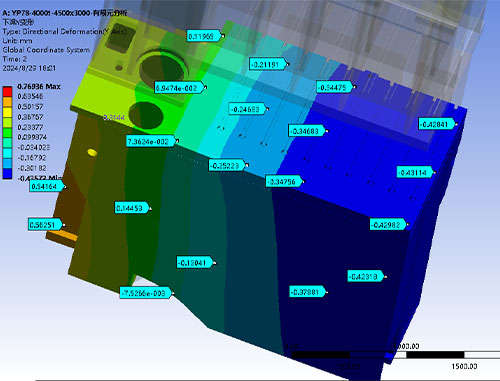

● High precision adjustment through the cylinder located at the four corners ensures that the horizontal accuracy of the slide is maintained during the downward movement.

● Suitable for thin-walled parts.

● Accumulator system : Pressure setting speed ≤1S.

● Servo system: Pressure setting speed ≤2S.

| Speed | V=1~5mm/s | V=10mm/s | V=20mm/s |

| Accurate | ±0.05 mm | ±0.10 mm | ±0.20 mm |

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom LFT-D Servo Hydraulic Press Manufacturers and Thermoplastic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

With the growing demand for high-performance composite materials in automotive lightweighting, rail transit, and aerospace industries, industrial production faces unprecedented challenges. Traditional molding technologies often struggle to balance speed, precision, and energy efficiency when handling long fiber thermoplastics (LFT), resulting in limited production efficiency, material waste, and inconsistent product quality. Against this backdrop, the LFT-D Servo Molding Press has gradually become the ideal choice for companies seeking high-performance, efficient molding solutions. The LFT-D Servo Molding Press combines servo motor technology with a precision hydraulic control system, enabling precise regulation of mold pressure, displacement, and speed. This high-precision energy distribution ensures uniform force during the forming process, guaranteeing the structural strength and surface quality of final components. This capability is indispensable for automotive structural parts, aerospace composite components, and high-demand rail transit seating products.

The uniqueness of the LFT-D Servo Molding Press lies in its precise servo-driven system. Unlike traditional hydraulic presses that rely on conventional valve-controlled systems, the servo system can adjust pressure and displacement in milliseconds, achieving dynamic response and precise control. This significantly reduces issues such as material fiber pull-out, bubbles, and misalignment during high-fiber material molding while also extending mold life and ensuring product consistency. Moreover, the high energy efficiency of servo drives helps manufacturers save electricity and reduce production costs, supporting environmentally friendly manufacturing. In addition, the LFT-D Servo Molding Press allows for multi-stage pressure curves and adjustable speed modes to meet the process requirements of different composite materials. For thick plates, large structural components, or complex curved parts, traditional hydraulic presses often face limitations in forming uniformity. The LFT-D Servo Press, with programmable control, can match mechanical parameters at every stage, ensuring optimal product precision and mechanical performance.

In modern manufacturing, equipment intelligence is not only a way to enhance production efficiency but also a key factor in improving product competitiveness. Wuxi PengdaHZ Intelligent Equipment Co., Ltd. leverages over 20 years of hydraulic press experience in developing the LFT-D Servo Molding Press. The company focuses exclusively on hydraulic forming equipment, with technical innovation, energy efficiency, and high-precision cutting as its core objectives. This focus ensures that Pengda’s LFT-D Servo Molding Press exceeds industry standards in performance and stability. Through advanced intelligent control systems, operators can intuitively set molding parameters such as pressure, speed, and temperature on a touchscreen interface. The system also monitors the forming process in real time and adjusts automatically. These intelligent features reduce human error and significantly improve production efficiency, especially in large-scale or complex part manufacturing.

The LFT-D Servo Molding Press is highly versatile. In the automotive industry, it is suitable for lightweight body structural parts, interior components, and seat frames, all requiring high forming precision and mechanical performance. In rail transit, high-strength composite seats and interior components demand long-term durability and structural safety. In aerospace, precision, stability, and energy efficiency are critical for composite part molding. Pengda’s LFT-D Servo Molding Press, with its high precision, stability, and energy-saving characteristics, meets these diverse and demanding industrial requirements, helping manufacturers enhance their core competitiveness.

As a professional hydraulic press manufacturer, Wuxi PengdaHZ Intelligent Equipment Co., Ltd. has over 20 years of industry experience. The company focuses solely on hydraulic forming equipment and prioritizes technical innovation and energy-efficient, precise cutting. This specialization ensures that every machine undergoes rigorous design and testing, delivering industry-leading stability, precision, and energy efficiency. Pengda hydraulic presses are widely used in automotive, rail transit, construction, aerospace, and car trim applications, providing high-performance, reliable molding solutions for global clients. By choosing Pengda’s LFT-D Servo Molding Press, companies gain not only efficient production equipment but also access to a comprehensive technical support and after-sales service system. From process optimization during R&D to troubleshooting during production, Pengda provides professional guidance to help clients maximize production benefits.

Facing increasingly stringent industrial manufacturing demands, the LFT-D Servo Molding Press, with its precise servo control, intelligent management, and energy-efficient features, is becoming the new standard in composite material forming. For companies pursuing high-quality, high-efficiency, and low-energy manufacturing, selecting Wuxi PengdaHZ Intelligent Equipment Co., Ltd.’s LFT-D Servo Molding Press represents not only a technological upgrade but also a crucial step toward future-oriented manufacturing. Amid trends such as automotive lightweighting, rail transit upgrades, and aerospace innovation, the LFT-D Servo Molding Press will undoubtedly become a core device for improving production efficiency and product quality. With continued technological advancement, the composite material manufacturing industry will enter a more efficient, intelligent, and sustainable era.