As a key piece of equipment in modern manufacturing, the thermoplastic press plays an irreplaceable role in material processing, composite material molding, and precision component manufacturing. With the widespread application of high-performance thermoplastic materials, the requirements for precision, efficiency, and automation in thermoplastic presses are increasing.

Content

I. Working Principle of a Thermoplastic Press

The core principle of a thermoplastic press is based on the physical properties of thermoplastic materials. When heated to a certain temperature, the molecular chains of thermoplastic materials gain sufficient energy, exhibiting plastic flow characteristics, allowing them to flow freely in the mold and fill complex mold spaces. During this process, the thermoplastic press achieves full material molding through a uniform heating system and precise pressure control.

The heating system of the equipment typically uses high-efficiency heating plates or mold heaters. Precise temperature control ensures the temperature uniformity of the material during processing, avoiding localized overheating or underheating. Simultaneously, the press's hydraulic or servo system provides stable and controllable pressure for molding, ensuring that the material maintains dimensional accuracy and surface quality during flow and solidification. Through the synergistic effect of temperature and pressure, thermoplastic presses enable the manufacture of parts with high precision and consistency.

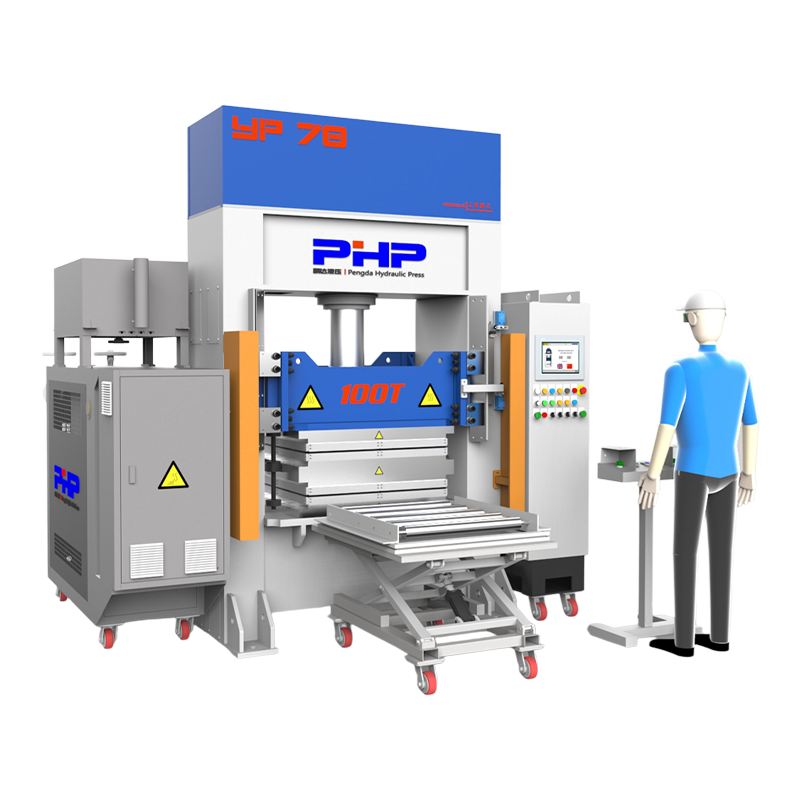

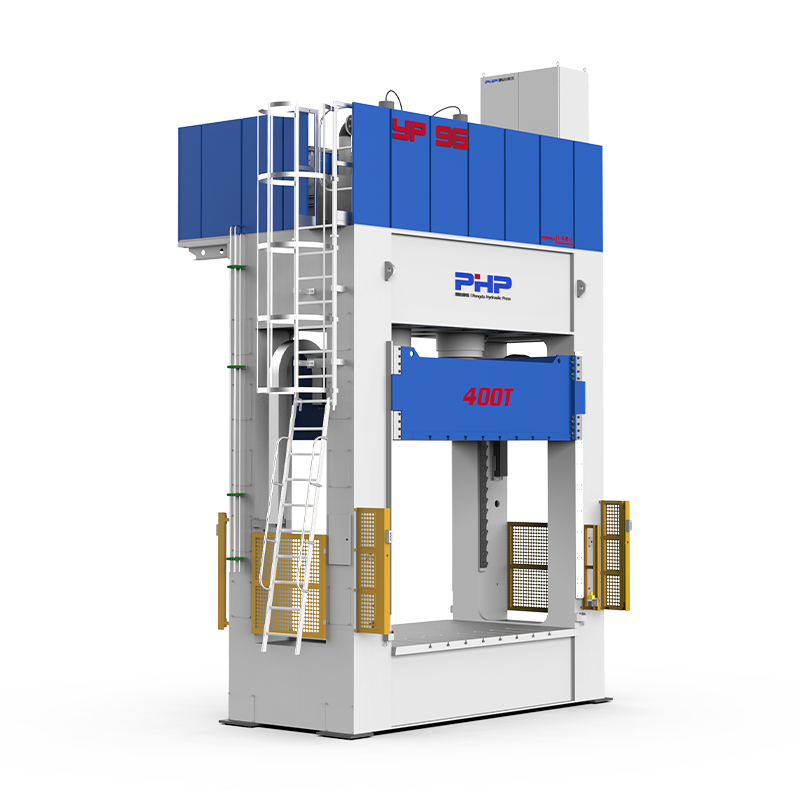

II. Structural Design and Core Components

The structural design of a thermoplastic press is crucial to its performance. A typical machine consists of a frame, heating system, pressure system, mold assembly, and control system. The frame is constructed of high-strength steel, and its rational mechanical design ensures stability and durability under high pressure. The heating system directly determines the uniformity and efficiency of material molding; high-precision temperature control technology significantly reduces energy consumption and improves product quality.

The pressure system is one of the core components of a thermoplastic press. Modern presses typically employ servo or hydraulic drives, using pressure sensors and closed-loop control to dynamically adjust the pressure. This not only ensures the density of the molded parts but also effectively controls the material flow rate, preventing warping, porosity, or stress concentration. The mold assembly directly reflects molding precision; its modular design and quick-change system enhance production flexibility and efficiency.

In terms of control systems, advanced thermoplastic presses are generally equipped with intelligent control platforms that can monitor temperature, pressure, heating time, and material status in real time, providing data recording and process optimization functions. This digital control not only improves operational convenience but also provides reliable assurance for the manufacture of high-precision parts.

III. Processing Performance and Material Adaptability

Thermoplastic presses have significant advantages in processing performance. Their greatest feature lies in their strong adaptability to different thermoplastic materials, including polymer composites, engineering plastics, and special functional thermoplastics. By adjusting temperature, pressure, and molding cycle, the equipment can achieve the optimal processing state of the material, fully utilizing its mechanical properties and surface characteristics.

Thermoplastic presses exhibit unique advantages in the molding of thick-walled parts and the manufacture of complex structures. Highly uniform heating and precise pressure control allow the material to flow fully and fill every corner of the mold during molding, thus ensuring the structural integrity and surface finish of the parts. Simultaneously, the equipment's process flexibility allows for rapid switching between different materials, meeting the diverse production needs of various products.

Thermoplastic presses also possess excellent repeatability and stability. In high-frequency production environments, the equipment maintains the dimensional accuracy and physical consistency of molded parts, reducing scrap rates and improving production efficiency. This makes thermoplastic presses widely applicable in high-end manufacturing, aerospace, automotive, and precision electronic component fields.

IV. Advantages of Thermoplastic Presses in Product Manufacturing

In the product manufacturing process, thermoplastic presses not only improve material processing efficiency but also play a crucial role in the performance of the final product. Their advantages are mainly reflected in the following aspects: The equipment can achieve high-precision molding, ensuring the geometric dimensions and surface quality of parts, meeting stringent industrial standards. By optimizing temperature and pressure parameters, thermoplastic presses can improve the internal structure of materials, enhancing mechanical properties and durability. The equipment's intelligent control system provides reliable data support for the production process, making the process controllable and traceable.

Thermoplastic presses also have advantages in environmental protection and energy conservation. Efficient heating systems and precise pressure control not only reduce energy consumption but also reduce waste generation, achieving green manufacturing goals. The equipment has relatively low maintenance costs, high stability and durability, and also reduces production and operational risks.

FAQ

Q1: What materials can a thermoplastic press process?

Thermoplastic presses are suitable for various thermoplastic materials, including polymer engineering plastics, composite materials, and functional thermoplastic materials. The equipment adapts to the molding requirements of different materials by adjusting temperature and pressure parameters.

Q2: What are the key factors for controlling molding precision in the equipment?

The core lies in temperature uniformity and pressure precision. Uniform heating ensures consistent material flowability, and the pressure system guarantees the density of parts, thereby achieving high-precision molding.

Q3: What are the main advantages of thermoplastic presses in industrial production?

The main advantages include high-precision molding, strong material adaptability, high repeatability, improved production efficiency, and energy saving and environmental protection.

Q4: What are the benefits of intelligent control of the equipment?

Intelligent control can monitor temperature, pressure, and material status in real time, enabling process optimization, production data tracking, and quality control, thus improving production stability.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский