2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

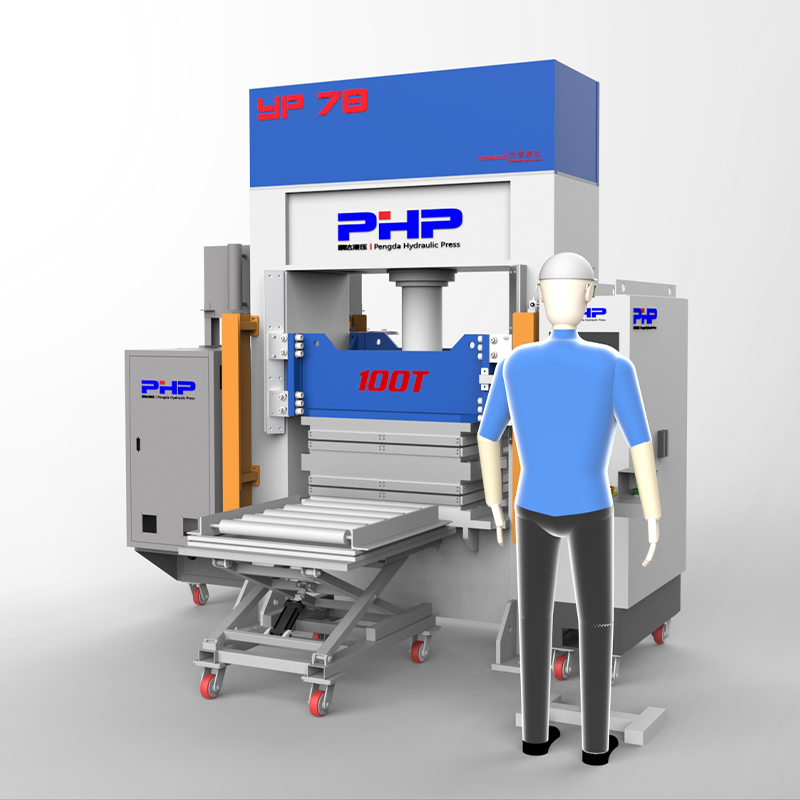

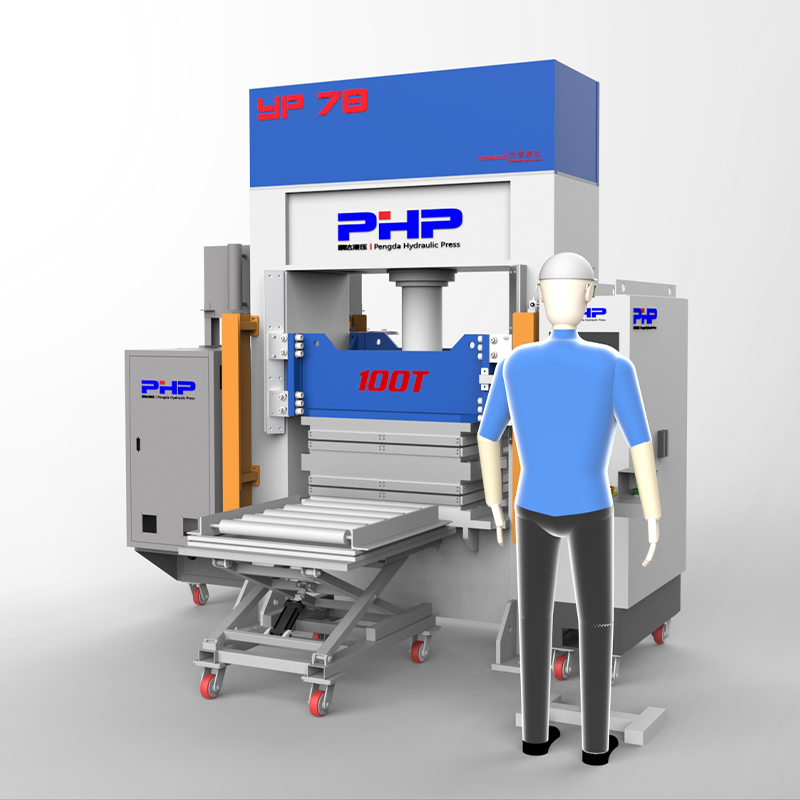

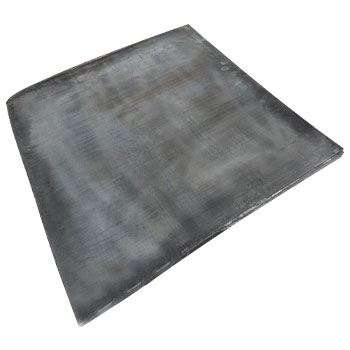

The Peek board forming press is a press specifically designed to solidify the unidirectional belt of Peek material into a single Peek board through ultra-high temperature. This device has two operating areas, the lower one for high-temperature heating and the upper one for cooling and shaping.

Peek Sheet Thermoforming Press

Heating / Cooling / Moving table

Pengda PEEK/PEAK sheet Thermoforming press focuses on the heating and forming process of PEEK/PEAK materials in the aerospace field. It is equipped with a moving table for easy material feeding and unloading. Temperature control system can achieve rapid heating and cooling of materials. The high-precision pressure and temperature control accuracy enables PEEK/PEAK sheets to be stably pressed.

|

|

|

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom Peek Sheet Thermoforming Press Manufacturers and Peek Sheet Thermoforming Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

In the evolving landscape of high-performance plastics, the PEEK (Polyether Ether Ketone) sheet has emerged as a material of choice for industries demanding thermal stability, mechanical strength, and chemical resistance. Central to processing this advanced polymer is the PEEK sheet thermoforming press, a technology that enables precision forming while maintaining material integrity. The role of this press extends beyond simple molding—it is a critical enabler for applications across aerospace, automotive, electronics, and energy sectors.

PEEK is a semi-crystalline thermoplastic that maintains mechanical properties under extreme temperatures. Its excellent wear resistance, low flammability, and high dimensional stability make it ideal for parts exposed to high stress and elevated temperatures. However, these characteristics also present significant challenges in thermoforming. Precise temperature control is required to soften the polymer without causing degradation, while forming pressure must be carefully regulated to avoid internal stress or warping.

A PEEK sheet thermoforming press addresses these challenges through advanced heating and servo-controlled pressure systems. These presses ensure uniform temperature distribution across the sheet, minimizing defects such as uneven wall thickness, voids, or surface imperfections. The precision of servo systems allows for repeatable forming cycles, essential for high-volume production of complex components.

Modern PEEK sheet thermoforming presses integrate several technological advancements to meet industry demands:

Energy Efficiency – Saving Energy-Servo System:

Energy consumption is a primary concern in high-temperature thermoforming. Servo-driven hydraulic systems optimize power usage by adjusting pressure and movement according to process requirements. This ensures that energy is used only when necessary, reducing operating costs while supporting green manufacturing principles.

Operational Stability – Continuous Lean Production:

High-quality PEEK parts require consistent process control. Thermoforming presses equipped with real-time monitoring and feedback systems enable continuous production without compromising precision. Lean production principles reduce downtime, improve yield, and maintain consistent product quality.

Safety – European Standard Compliance:

Handling high-temperature polymers demands strict safety measures. Modern presses conform to European safety standards, incorporating features such as emergency stops, protective enclosures, and automated temperature control to prevent operator hazards.

Space Optimization – Smart Factory Integration:

Advanced press designs allow integration into automated production lines, saving valuable factory floor space. Compact layouts with multifunctional capabilities—heating, forming, and cooling—enhance workflow efficiency and reduce material handling time.

PEEK sheet thermoforming presses are increasingly critical in multiple high-performance sectors:

The combination of high-temperature tolerance and chemical resistance makes PEEK sheet parts particularly suitable for environments where other plastics fail.

Wuxi PengdaHZ Intelligent Equipment Co., Ltd. is at the forefront of non-metallic hydraulic press manufacturing, with a strong commitment to green industry principles and continuous innovation. Their PHP (Pengda Hydraulic Press) line demonstrates leadership in energy-saving hydraulic systems, producing advanced servo presses for diverse industrial applications.

PHP focuses on two main categories of non-metallic molding presses:

Servo Composite Hydraulic Presses: Designed for high-temperature and high-performance applications such as SMC, LFT-D, GMT, HP-RTM, STM, and carbon fiber composites. These presses are instrumental in industries like aerospace, rail transit, urban construction, and new energy vehicles.

Servo Interior Parts Hydraulic Presses: Tailored for automotive interior applications, including molding, compounding, punching, and heating. These presses manufacture components such as overhead liners, carpets, luggage compartments, seats, and soundproofing parts.

Key equipment features include operational stability, energy efficiency, space optimization, and adherence to international safety standards. Fully automated production lines allow integrated services, enhancing process reliability and reducing manual intervention.

The PEEK sheet thermoforming press integrates servo-controlled hydraulic systems that provide smooth and precise pressure adjustments, critical for processing high-performance polymers. Unlike traditional mechanical presses, these systems reduce vibration and shock during forming, preserving material properties.

Advanced temperature control systems maintain uniform heating across the PEEK sheet, preventing localized overheating or thermal degradation. Moreover, the press can be programmed for complex forming cycles, including multi-stage heating and controlled cooling, resulting in high-precision components with superior surface finish and structural integrity.

Successful thermoforming of PEEK sheets requires attention to several operational parameters:

PHP presses incorporate digital monitoring systems to track these parameters in real-time, enabling proactive adjustments and consistent quality output.

The PEEK sheet thermoforming press is not merely a tool but a cornerstone of modern high-performance polymer manufacturing. By combining energy efficiency, precise control, and operational stability, these presses enable the production of complex, high-quality components across demanding industries. Wuxi PengdaHZ Intelligent Equipment Co., Ltd. fully demonstrates how technological innovation in servo hydraulic presses can drive improvements in industrial efficiency and the development of sustainable manufacturing practices.

Investing in advanced PEEK sheet thermoforming press technology ensures reliable production, reduced operational risk, and long-term competitiveness in sectors where precision, durability, and high performance are non-negotiable.