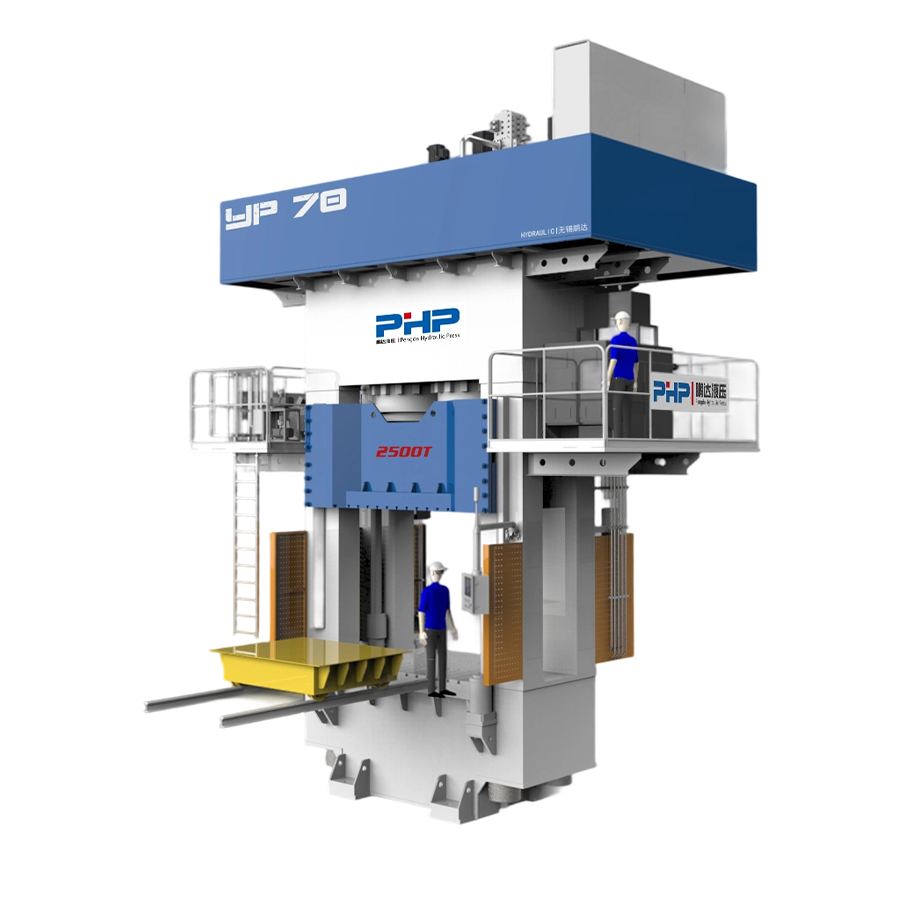

In modern manufacturing, compression molding, as a mature plastic processing technology, has been widely used in the production of various products. Whether in home appliances, automobiles, electronic equipment, or daily consumer goods, the technical advantages and unique characteristics of compression molding have made it an indispensable part of the plastic processing industry.

Content

Basic Principles of Compression Molding

Compression molding is a processing technology that uses high temperature and high pressure to press plastic materials (usually thermosetting resins or rubber) into a mold, where they are heated and pressurized to solidify and form the desired shape. The core of this process is to complete the transition from flow to solidification in a relatively short time through external pressure and heat. Compared with other molding methods, one of the biggest advantages of compression molding is its ability to fully utilize the fluidity of the material, ensuring perfect replication of mold details.

In the entire compression molding process, the raw materials are usually pre-cut into sheets or granules. These materials are placed in a preheated mold, and then uniform pressure is applied through an external pressing device. As the mold heats up, the plastic or rubber material quickly melts, eventually filling all the cavities of the mold and solidifying during the cooling process. Because this process is affected by multiple factors such as temperature and pressure, compression molding usually requires precise process control and equipment adjustment.

Characteristics of Compression Molding Process

1. Process Flexibility

The compression molding process has high flexibility and is suitable for a variety of different types of raw materials, especially in the processing of thermosetting plastics, rubber, and certain composite materials. Compared with other molding processes, compression molding has simpler mold requirements and can be operated with relatively basic equipment. In addition, compression molding can adjust the mold design as needed to meet the production needs of different products.

2. High Material Utilization Rate

Compared with processes such as injection molding, compression molding has significant advantages in material utilization. Because the mold gradually expands and applies pressure evenly during the heating process, the fluidity of the material can be fully utilized. This allows compression molding to minimize raw material waste during the production process, thereby reducing production costs.

3. Suitable for Processing Complex Shapes

Due to the high pressure applied during the compression molding process, the material can fully fill every part of the mold, making it suitable for producing products with complex shapes and high detail requirements. During processing, the material is evenly distributed in the mold, ensuring the shape and dimensional accuracy of the product. Therefore, compression molding is particularly advantageous for small and complex parts.

4. Longer Molding Cycle

Compared to some other molding processes, compression molding typically has a longer molding cycle. This is because the molding process involves not only the melting and filling of the material but also a period of curing. Nevertheless, the efficiency of this process and the quality of the products often compensate for this, and it is still widely used in many demanding applications.

Applications of Compression Molding

Compression molding technology is widely used in various industries, particularly in the manufacturing of products requiring high strength, heat resistance, and corrosion resistance.

Automotive Industry

In the automotive industry, compression molding is mainly used to produce high-strength, high-temperature-resistant components such as seals, rubber gaskets, and automotive interior parts. These parts require good sealing, aging resistance, and high-temperature resistance, and compression molding technology can meet these requirements.

Electronic Devices

Compression molding is also widely used in the electronics industry. Many electronic product casings, conductive connectors, and protective films utilize this process. Compression molding can produce electronic components with uniform quality and stable performance, improving product lifespan and reliability.

Medical Devices

In the medical device field, compression molding is used to produce precise medical components, such as catheters, seals, and various fine plastic or rubber parts. These components usually require high precision and a high degree of safety, and compression molding can meet the requirements for molding accuracy and material stability.

Household Appliances

Compression molding technology is also widely used in household appliance products, especially in the production of components operating in high-temperature or high-pressure environments. For example, the casings, interfaces, and accessories of household appliances are often manufactured using compression molding. Compression molding ensures the stability and safety of these components in high-load working environments.

Frequently Asked Questions (FAQ)

1. What are the main advantages of compression molding?

The main advantages of compression molding include high process flexibility, high material utilization, and suitability for processing complex shapes. Its unique process characteristics give it widespread applications in many demanding industries.

2. Why is compression molding commonly used for rubber and thermosetting plastics?

Rubber and thermosetting plastics typically require curing under heat and pressure. Compression molding provides the necessary heat and pressure to help these materials complete the curing process, thus ensuring their excellent performance.

3. What are the differences between compression molding and injection molding?

Compared to injection molding, compression molding generally has a longer molding cycle, and injection molding requires more complex mold designs. However, compression molding has advantages in material utilization and processing of complex shapes, and is particularly suitable for producing high-strength, high-temperature resistant products.

4. What are the limitations of compression molding?

The main limitations of compression molding are the longer molding cycle and the higher equipment investment required. Precise control of temperature and pressure is crucial for product quality, therefore, it requires a higher level of operational skill.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский