Content

Introduction

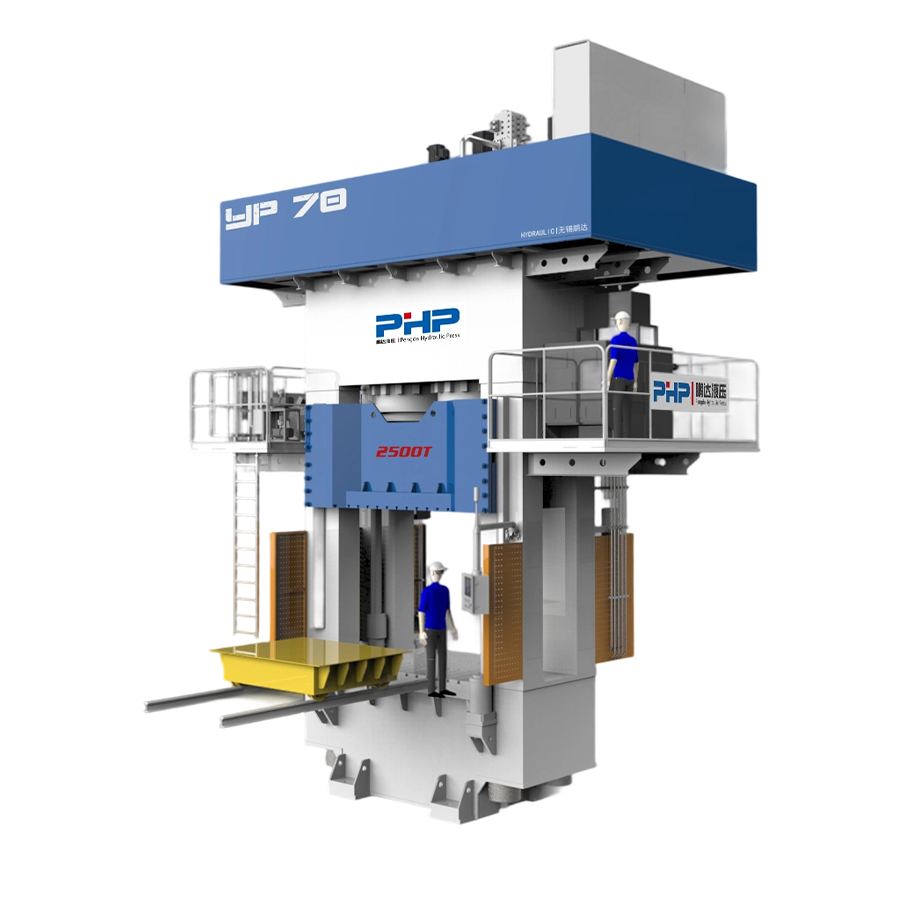

In modern manufacturing, hydraulic presses are almost ubiquitous, and the SMC hydraulic press, with its superior performance, reliable stability, and flexible applicability, has become the preferred equipment for many factories and workshops. Whether in automotive parts forming, metal stamping, or composite material processing, the SMC hydraulic press can leverage its powerful production capabilities and precise control advantages.

Core Structure and Technical Principles of the SMC Hydraulic Press

The core of the SMC hydraulic press lies in the design of its hydraulic system. Compared to traditional mechanical press equipment, the hydraulic system utilizes the incompressibility of liquids to achieve smooth power transmission, thus ensuring the accuracy and stability of each stamping or forming process. SMC hydraulic presses typically employ a high-strength steel structure, combined with precisely machined hydraulic cylinders and pistons, to form a high-rigidity frame. This not only ensures the stability of the equipment during long-term operation but also greatly enhances operational safety.

In terms of hydraulic control, the SMC hydraulic press uses advanced proportional valves and servo control systems to achieve precise adjustment of pressure, speed, and stroke. Whether it's low-speed forming or high-speed stamping, the equipment can automatically adjust the output force according to process requirements, achieving high-precision processing. This highly automated control capability allows the SMC hydraulic press to maintain high repeatability and stable performance even in complex process environments.

Efficient and Energy-Saving Power System

The SMC hydraulic press focuses on efficiency and energy saving in its power system design. By optimizing the hydraulic oil circuit design to reduce energy loss, and combining it with intelligent control technology, the equipment can significantly reduce power consumption without compromising production efficiency. The coordinated operation of the hydraulic pump, accumulator, and servo motor ensures efficient energy transfer at every stage of system startup, operation, and shutdown. At the same time, the recycling of hydraulic oil and the temperature control system ensure that the equipment maintains a stable temperature during high-intensity work, extending the lifespan of core components.

This power system not only reduces operating costs but also provides technical support for manufacturing companies in terms of energy saving and emission reduction. Through precise control of the hydraulic system, the SMC hydraulic press achieves stable operation under high load while reducing mechanical wear and extending the overall lifespan of the equipment.

Processing Advantages Brought by Precision Control

In modern manufacturing, product precision directly determines market competitiveness. SMC hydraulic presses, through their digital control system, achieve precise adjustment of pressing force, stroke speed, and dwell time. Whether it's deep drawing of thick metal plates or lamination molding of composite materials, the equipment maintains uniform force distribution, reducing material deformation errors and defect rates.

The SMC hydraulic press control system supports real-time data acquisition and feedback adjustment. This means the equipment can automatically optimize working parameters based on mechanical changes during the production process, ensuring that every product meets design standards. The high repeatability and consistency of the processing results give SMC hydraulic presses an irreplaceable advantage in the field of precision manufacturing.

Safety and Humanized Design

The safety of industrial equipment is always a key concern for users. SMC hydraulic presses demonstrate a high degree of humanization in both structural design and operating interface. Safety measures such as protective covers, two-hand operation controls, and emergency stop devices ensure the safety of operators during equipment operation. At the same time, the hydraulic system's buffering and pressure monitoring functions prevent overload or accidental impact from causing equipment damage or production accidents.

The user-friendly operating interface also provides convenience for operators. The touchscreen and intelligent control module allow operators to easily set processing parameters, monitor real-time status, and quickly adjust in case of abnormalities. This design not only improves production efficiency but also lowers the barrier to entry for equipment use, allowing companies to quickly train operators and achieve efficient production.

Adaptability to Multiple Applications

Thanks to its precision, stability, and efficiency, SMC hydraulic presses are widely used in various fields, including automotive manufacturing, aerospace, mechanical processing, and composite material processing. The equipment can handle a variety of materials and complex processes, from hard metal plates to flexible composite materials, achieving precise stamping and forming. At the same time, the modular design and flexible control system allow it to quickly adapt to the needs of different production lines, improving overall factory capacity.

The SMC hydraulic press is not just a simple mechanical device, but an important tool for achieving high-quality, high-efficiency processing in modern industrial production. Through precise hydraulic control, intelligent operation, and a high-rigidity structure, the equipment improves production efficiency while ensuring product consistency and reliability.

FAQ

Q: What are the core advantages of the SMC hydraulic press?

A: The core advantages lie in its high-precision hydraulic control system, stable structural design, and energy-efficient power system. These characteristics ensure that the equipment maintains high-quality output in a variety of processing scenarios.

Q: Is equipment maintenance complicated?

A: The SMC hydraulic press features a modular design and intelligent monitoring system, resulting in low maintenance requirements. Routine maintenance primarily focuses on hydraulic oil management and key component inspections.

Q: What types of processing techniques is it suitable for?

A: It is suitable for various industrial processing techniques, including metal stamping, deep drawing, composite material lamination, and high-precision forming, and can handle a variety of materials and thicknesses.

Q: Does operation require professional skills?

A: The equipment has a user-friendly interface and a high degree of intelligence, allowing even ordinary operators to quickly master its operation after training, significantly lowering the operating threshold.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский