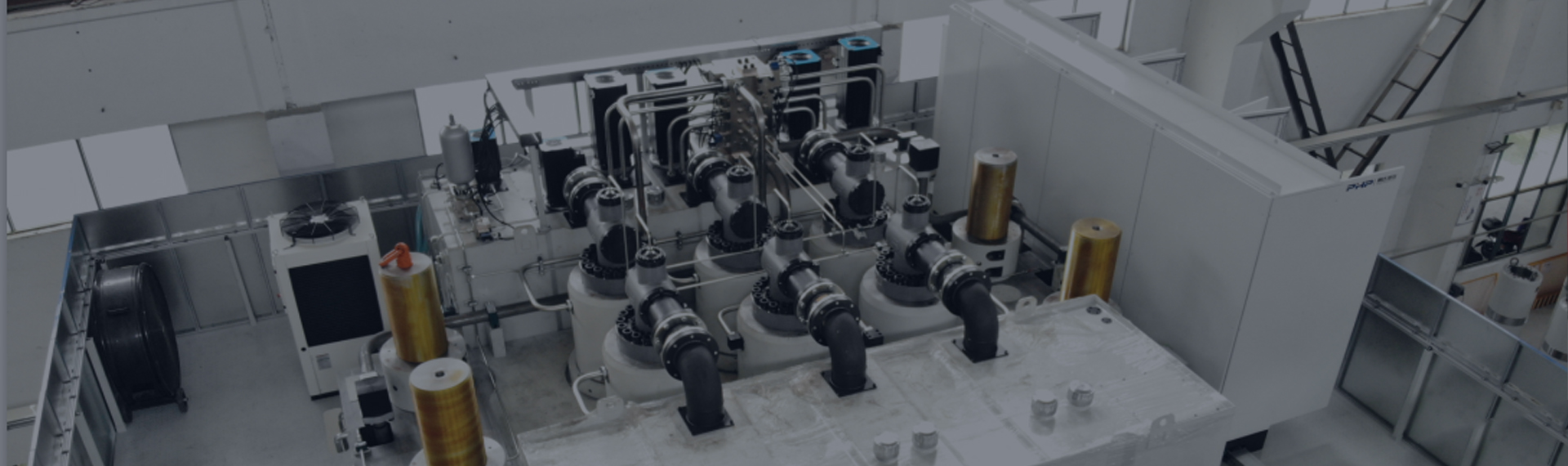

In modern manufacturing, hydraulic molding presses have become essential equipment for various material forming processes due to their high precision, high efficiency, and wide applicability. Whether it's plastics, rubber, or composite materials, hydraulic molding machines can achieve high-quality molding of complex structures through stable pressure control and precise temperature control systems. In product development and mass production, it not only improves production efficiency but also significantly ensures the consistency and reliability of the finished products.

Content

- 1 Core Structure and Working Principle of Hydraulic Molding Machines

- 2 Advantages of Hydraulic Molding Machines

- 3 Applications and Suitability of Hydraulic Forming Machines

- 4 Key Selection Points for Hydraulic Forming Machines

- 5 FAQ: Frequently Asked Questions about Hydraulic Forming Machines

- 5.1 Q: What are the advantages of hydraulic forming machines compared to mechanical presses?

- 5.2 Q: What materials are suitable for hydraulic forming machines?

- 5.3 Q: How to ensure the stability of a hydraulic forming machine?

- 5.4 Q: Is the operation of a hydraulic forming machine complex?

- 5.5 Q: What are some common problems encountered during the forming process with hydraulic forming machines?

Core Structure and Working Principle of Hydraulic Molding Machines

A hydraulic molding machine mainly consists of a hydraulic system, a worktable, a mold system, a control system, and safety protection devices. The hydraulic system is its core power source, using a hydraulic pump to pressurize and transmit hydraulic fluid to the actuators, achieving mold closing, pressure holding, and molding actions. Compared to mechanical presses, hydraulic molding machines can achieve adjustable cushioning and constant pressure control, which is particularly crucial for molding materials with uneven thickness or complex structures.

During operation, the hydraulic system monitors pressure and displacement in real time through valves and sensors, ensuring the accuracy and repeatability of each molding cycle. The mold system is precisely machined according to product design requirements; its closing accuracy and wear resistance directly affect the surface quality and dimensional accuracy of the final product. The control system typically uses an advanced PLC or touchscreen interface, allowing operators to set pressure, speed, holding time, and temperature control parameters in real time, enabling fully automatic or semi-automatic operation.

Advantages of Hydraulic Molding Machines

Hydraulic molding machines have significant advantages in material molding. First is pressure controllability. The hydraulic system can automatically adjust the pressure during the molding process according to material flow and thickness changes, ensuring uniform product density and preventing pores or warping. Second is temperature control accuracy. Modern hydraulic molding machines are equipped with high-precision heating and cooling systems, allowing materials to reach their optimal flow state at different temperatures, thus ensuring a smooth molded surface and stable dimensions.

In addition, hydraulic molding machines also have advantages in energy consumption and operational safety. Compared to traditional mechanical presses, they have higher energy utilization efficiency, smoother pressure adjustment, reduced mechanical impact, and multiple safety protection measures, such as overload protection, mold anti-pinch design, and emergency stop functions, significantly reducing operating risks.

Applications and Suitability of Hydraulic Forming Machines

Due to their high precision and flexibility, hydraulic forming machines are widely used in the manufacturing of plastic parts, rubber products, composite material components, and electronic components. Whether for single-piece production or mass production, they can guarantee product repeatability and stability. The diversity of molds, combined with the precise control of the hydraulic forming machine, makes it possible to form complex curved surfaces, thin-walled structures, and porous products.

Hydraulic forming machines are particularly outstanding in composite material processing. By precisely controlling pressure and temperature, they can complete material curing and forming in a short time, reducing material waste and improving the mechanical strength and structural stability of the finished product. This high precision and efficiency make hydraulic forming machines an important tool for R&D and high-end manufacturing.

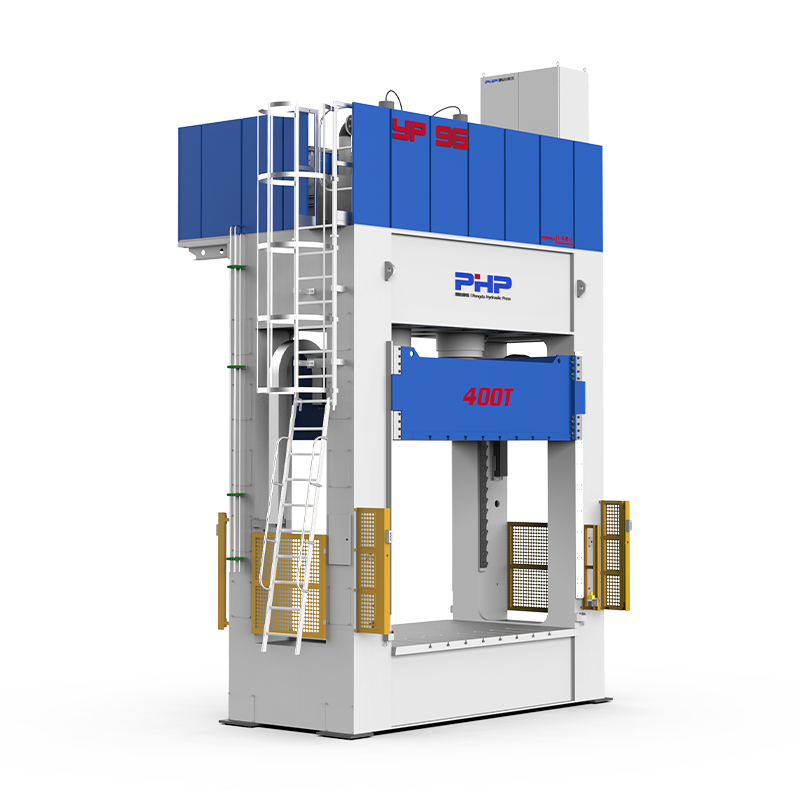

Key Selection Points for Hydraulic Forming Machines

When selecting a hydraulic forming machine, core factors include pressure range, mold compatibility, control accuracy, and ease of maintenance. The pressure range should be matched to the forming material and product structure requirements to ensure stable performance even under high pressure. Mold compatibility directly affects production efficiency and product quality; the synergistic capability of high-precision molds and the hydraulic system is a crucial selection criterion. The intelligence level of the control system also determines ease of operation and forming stability, while facilitating subsequent data management and process optimization. Ease of maintenance relates to long-term production efficiency, including the convenience of hydraulic system maintenance, lubrication, and electrical component inspection.

FAQ: Frequently Asked Questions about Hydraulic Forming Machines

Q: What are the advantages of hydraulic forming machines compared to mechanical presses?

A: Hydraulic forming machines have significant advantages in pressure control, temperature control accuracy, operational safety, and adaptability to complex molds, making them particularly suitable for products requiring high dimensional accuracy and surface quality.

Q: What materials are suitable for hydraulic forming machines?

A: Hydraulic forming machines can process plastics, rubber, composite materials, and electronic component packaging materials, and are especially suitable for forming materials with varying thicknesses, curved surfaces, and complex structures.

Q: How to ensure the stability of a hydraulic forming machine?

A: Stability mainly depends on the design of the hydraulic system, mold accuracy, real-time monitoring of the control system, and daily maintenance. High-quality hydraulic pumps and precision valves are key.

Q: Is the operation of a hydraulic forming machine complex?

A: Modern hydraulic forming machines are often equipped with intelligent control systems and touch screen interfaces, allowing for automated or semi-automated operation, significantly reducing the difficulty of operation.

Q: What are some common problems encountered during the forming process with hydraulic forming machines?

A: Common problems include air bubbles, warping, and dimensional deviations, which can usually be resolved through pressure adjustment, temperature control optimization, and mold precision control.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский