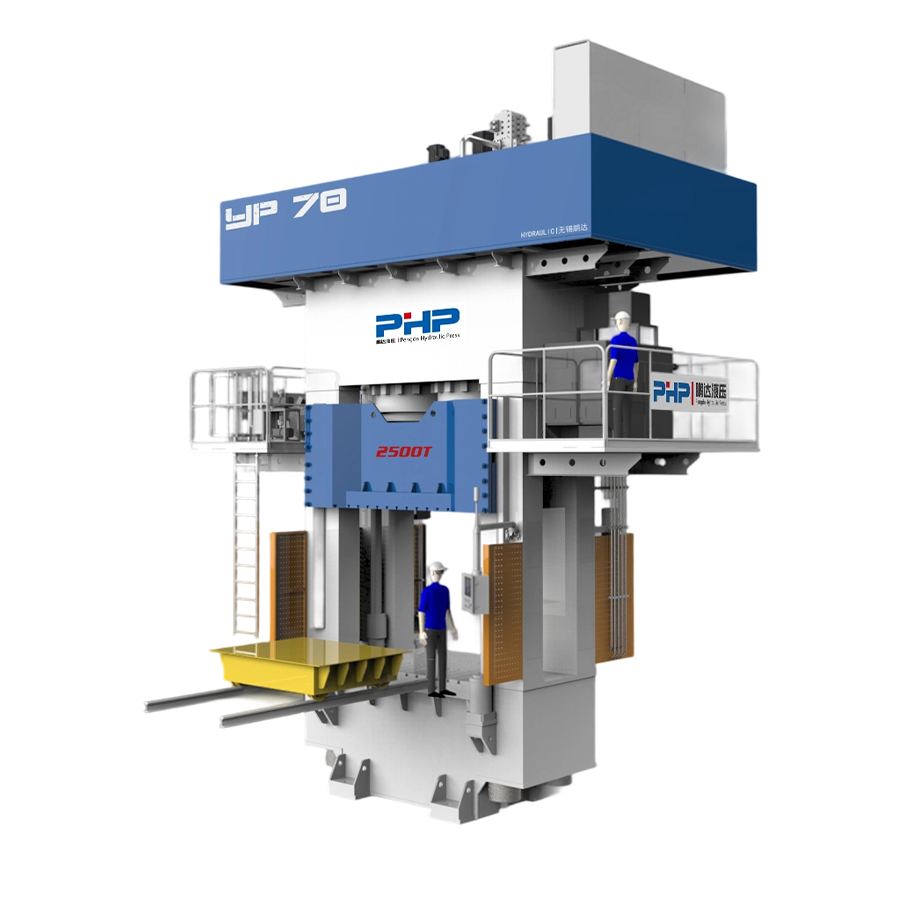

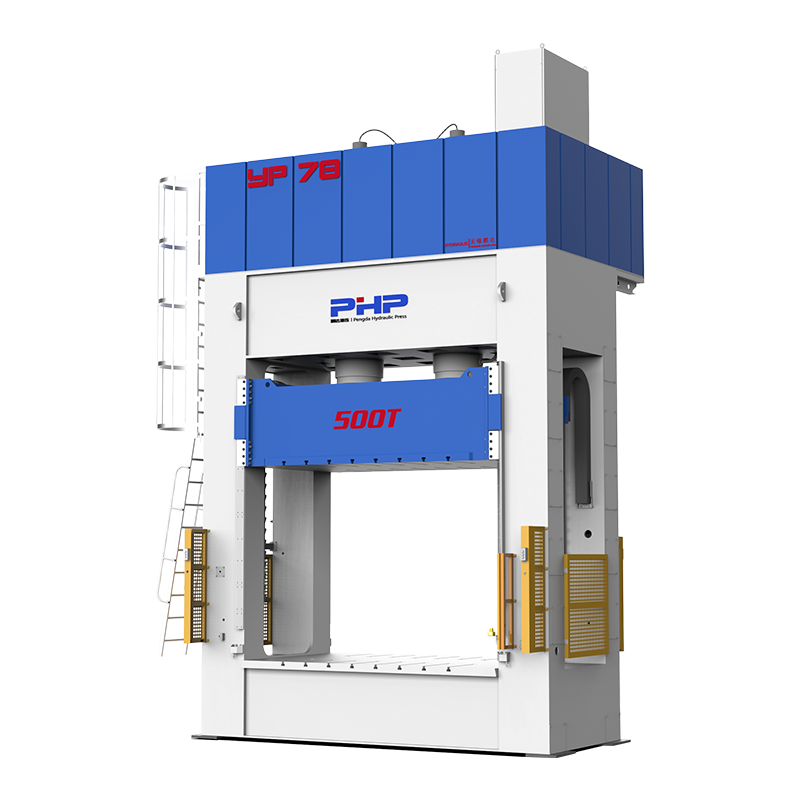

With over 20 years of expertise in the automotive industry, PHP(Pengda Hydraulic Press) has developed servo composite hydraulic presses and servo auto trim hydraulic presses tailored for automotive interiors, exteriors, and new energy applications—effectively addressing the limitations of traditional presses such as high energy use, low precision, and slow response.

In addition, we provide fully automated production line solutions, delivering optimal performance in energy efficiency, safety, precision, and stability. All equipment complies with international standards and safety regulations, including CE, UL, CAS, and NR10.

At PHP(Pengda Hydraulic Press), we uphold a commitment to quality, technological leadership, and continuous innovation, striving to deliver the best service to every customer in the automotive industry.

Technology Developing

● HP-RTM molding process: Improves molding efficiency and is suitable for large parts with complex structures;

● SMC/BMC compression molding: Achieving high-strength, batch automatic production;

● Integrated molding process of compression and injection process: Higher product performance and faster production efficiency;

● Thermoplastic molding technology: Materials are recyclable and have better recyclability;

● Servo drive and intelligent control: Improve the accuracy and flexibility of the molding process, reduce material waste;

● Improved automation and digitization: Moving towards Industry 4.0 to meet the needs of mass customization.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский