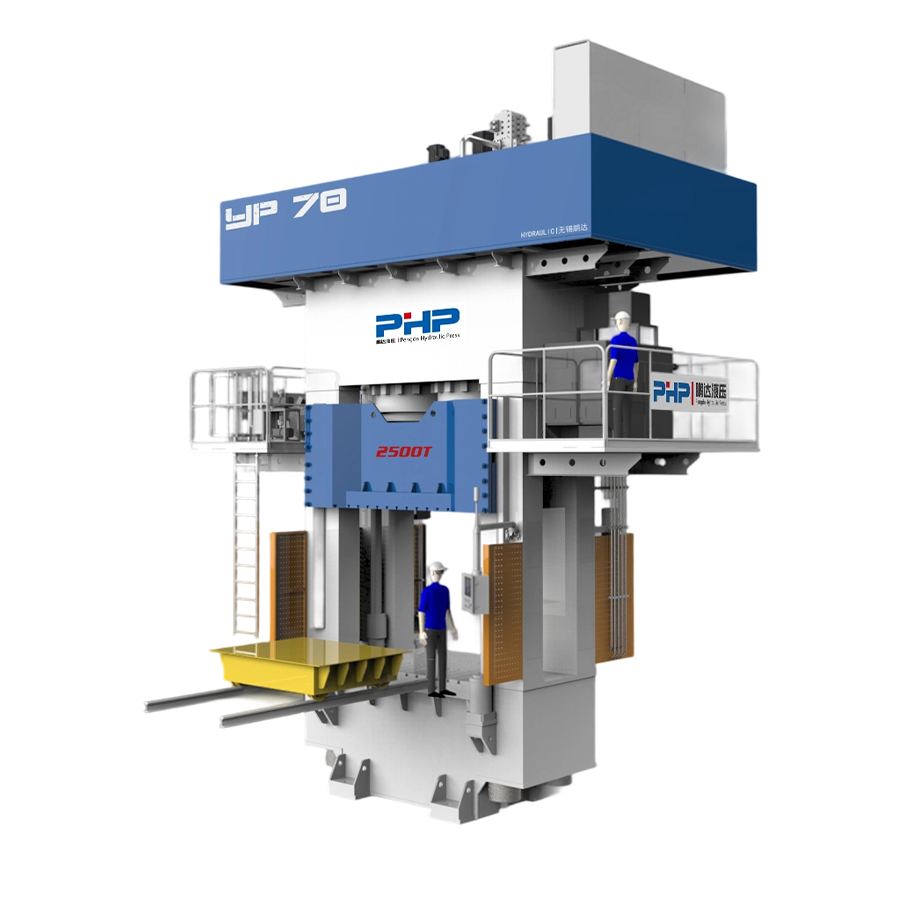

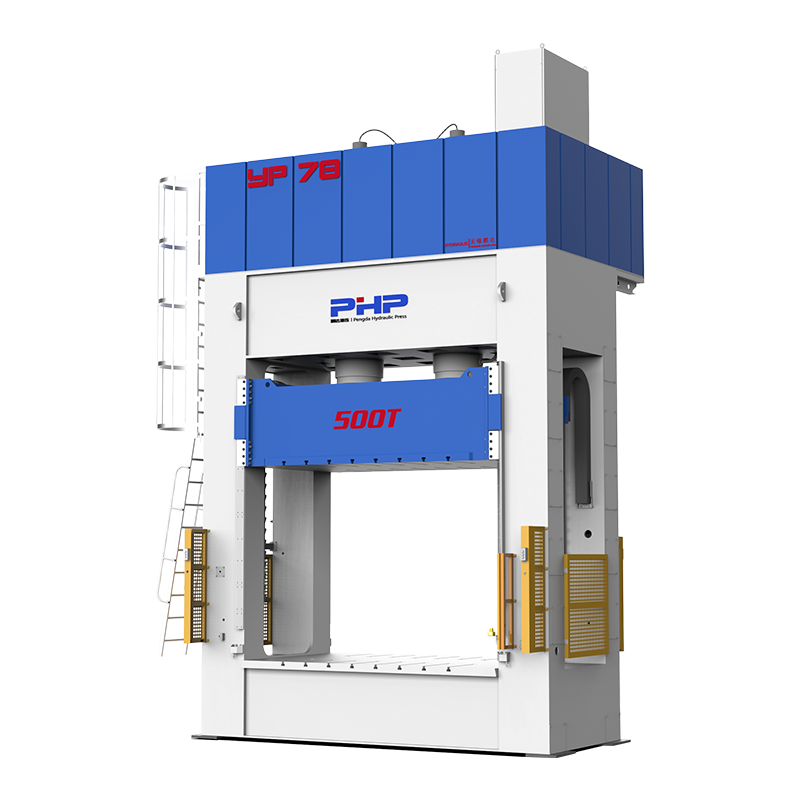

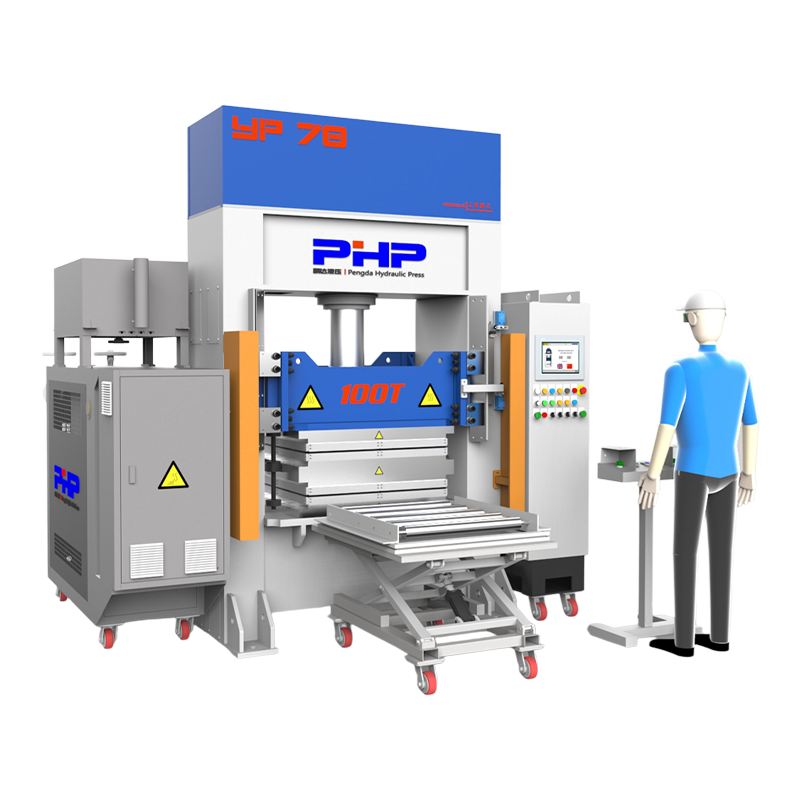

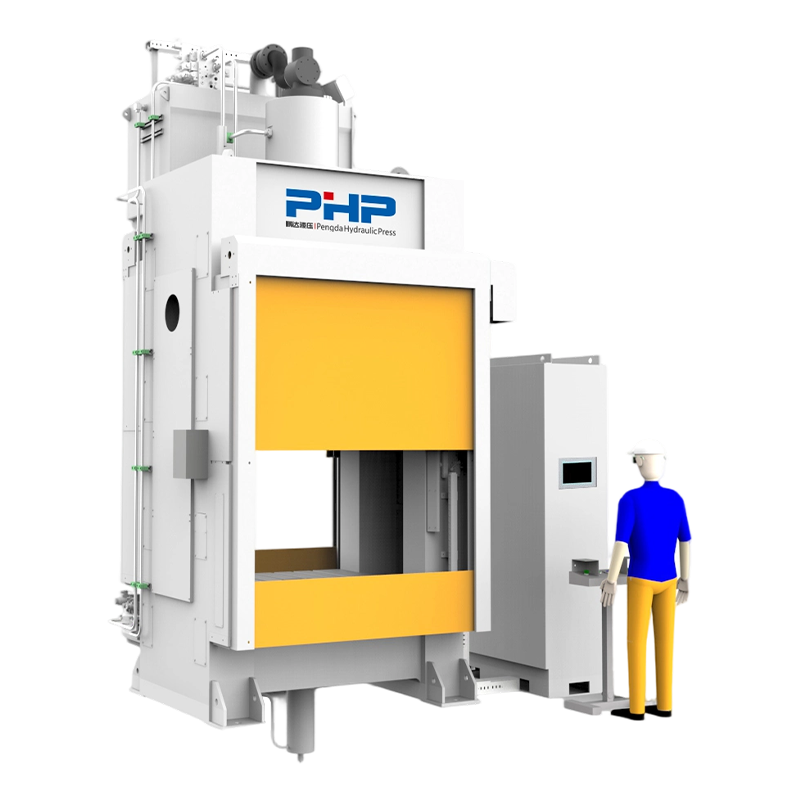

Beyond aerospace, transportation, and urban construction, PHP(Pengda Hydraulic Press) presses are widely used in the production of high-performance composite components across diverse sectors. Typical applications include drone blades, helicopter rotor blades, low-voltage electrical components, sports equipment, and wind turbine blades. With high precision, stable performance, and versatile process adaptability, PHP presses meet varied material and production requirements. Automated and customized solutions help these industries improve efficiency, product quality, and process consistency.

PHP(Pengda Hydraulic Press) Press Advantages

PHP(Pengda Hydraulic Press) presses combine servo hydraulic and intelligent control technologies with the following core advantages:

● High Precision: Accurate control of pressure, temperature, and stroke ensures consistency and structural stability of complex parts.

● High Efficiency: Shortened molding cycles improve productivity.

● Energy Saving & Eco-friendly: Servo-driven systems reduce energy consumption and comply with international environmental and safety standards.

● Stable & Reliable: High-rigidity structure ensures smooth operation and long-term reliability under heavy loads.

● Intelligent & Automated: Supports automated loading/unloading, mold heating/cooling, online monitoring, and production management.

● Versatile Process Compatibility: Compatible with SMC, LFT-D, HP-RTM, and other composite molding processes.

● Customizable Solutions: Tailored equipment and production lines meet specific customer needs, maximizing efficiency.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский