2026/01/30

2026/01/30

Differences Between CE Standard Hydraulic Presses and Domestic Standard Hydraulic Presses

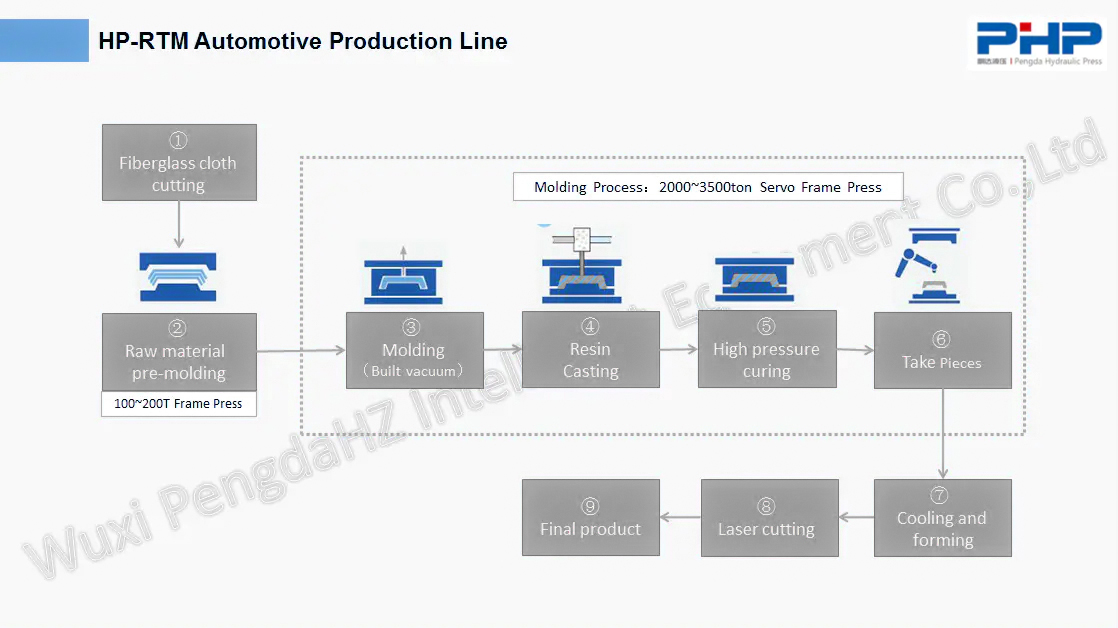

HP-RTM is a new technology that combines traditional RTM technology with high pressure molding technology, which can greatly shorten the production time and reduce the production cost while ensuring product quality.

HP-RTM molded parts have the advantages of light weight, high strength, good fatigue resistance, high damage safety, good corrosion resistance, etc., and are widely used in aerospace, high-speed rail, electronics, military and other fields.

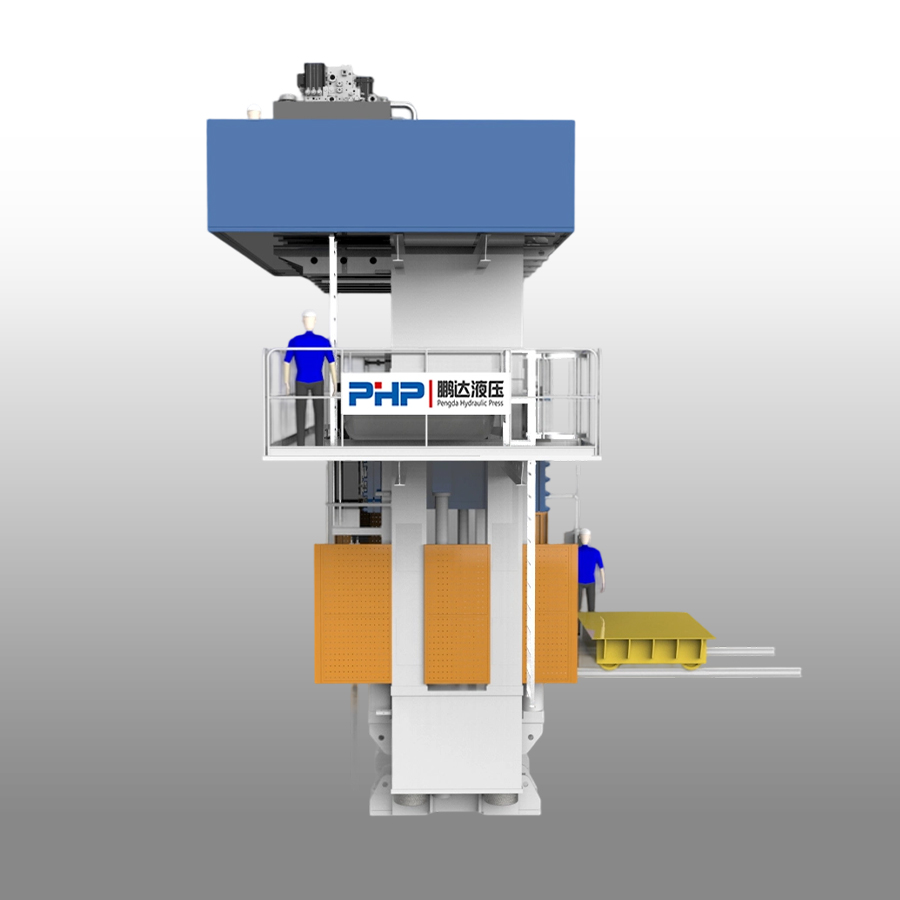

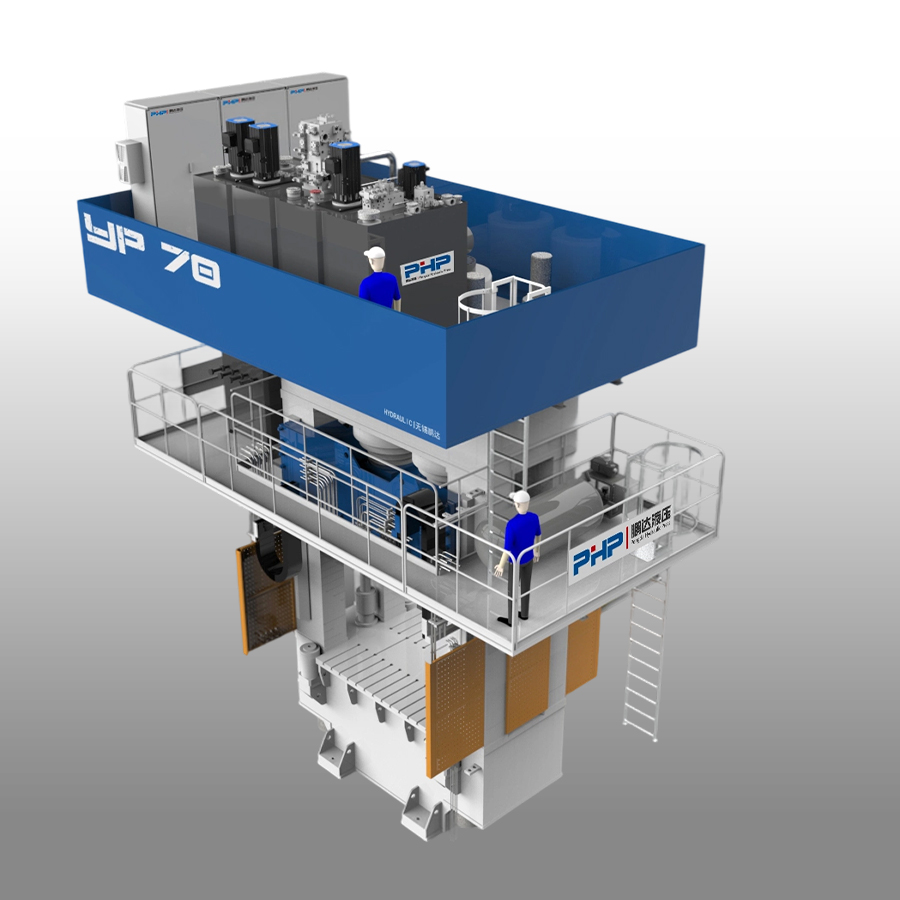

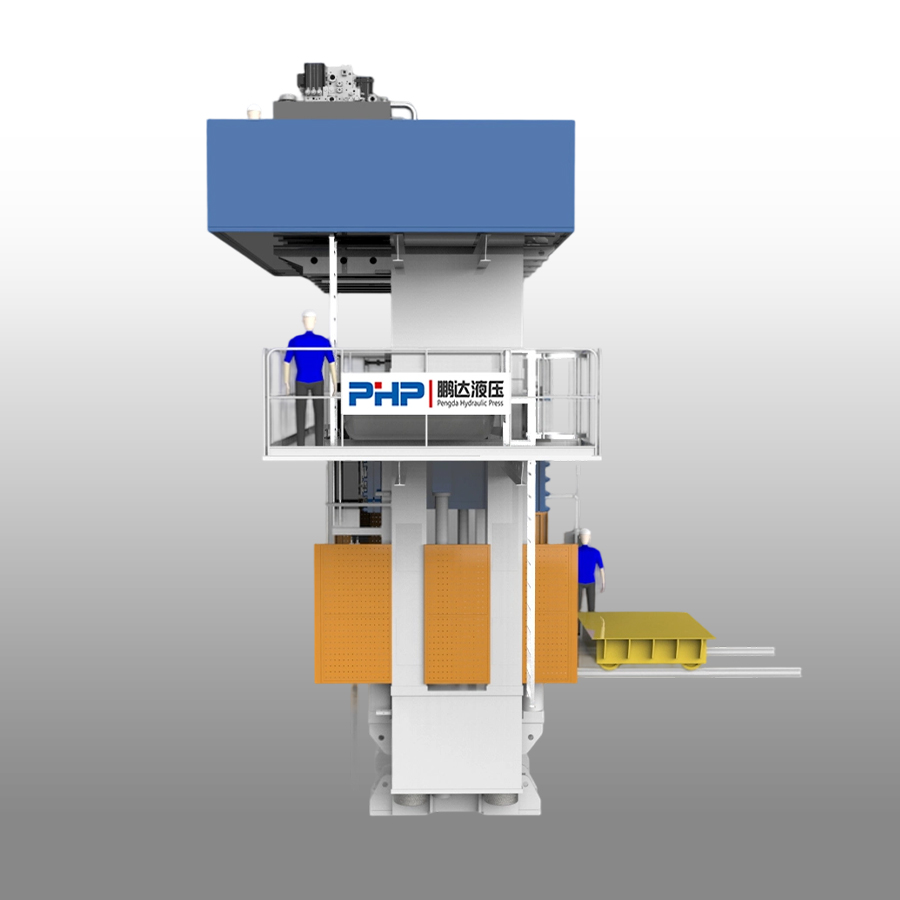

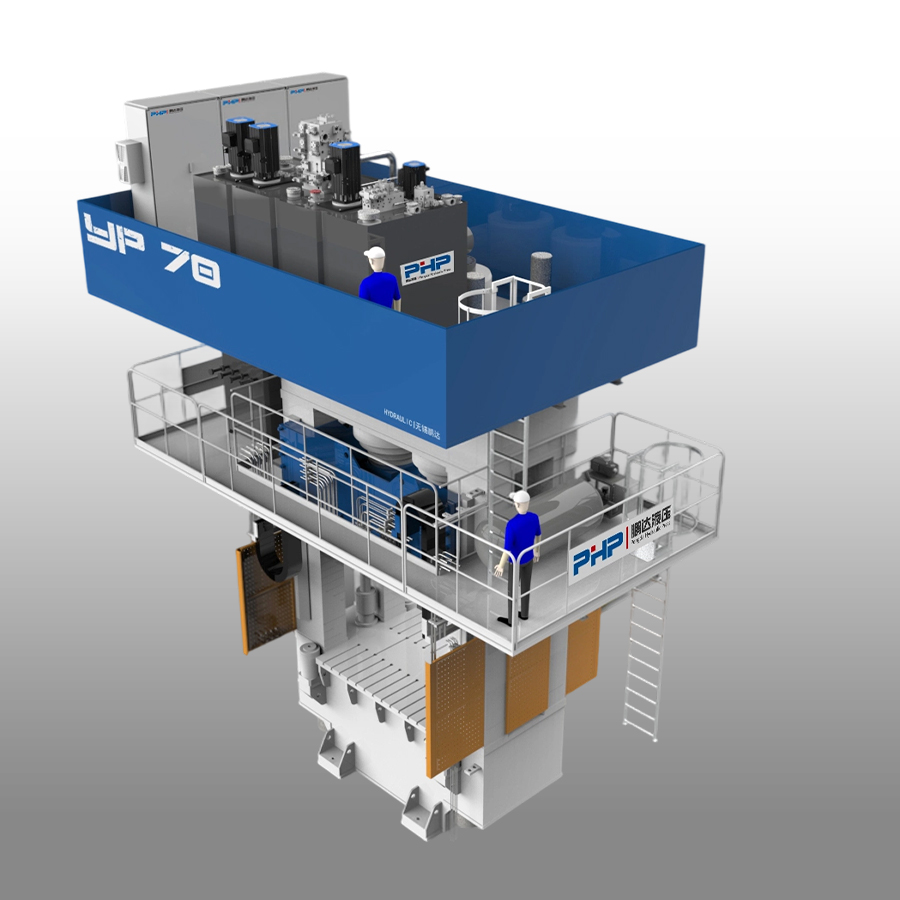

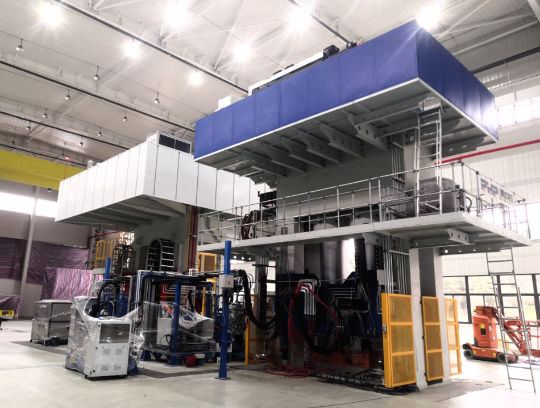

HP-RTM Servo Composite Hydraulic Press

Complete High-Pressure RTM Process Solution

HP-RTM (High Pressure Resin Transfer Molding) is the abbreviation for the high-pressure resin transfer molding process. It refers to the molding process of composite material products by using high-pressure pressure to mix and inject resin into a vacuum sealed mold pre-laid with fiber-reinforced materials and pre-embedded parts, and through resin flow filling, impregnation, curing, and demolding.

|

|

|

| New Battery Cover | Energy Storage Box | Leaf Spring |

| Type | Unit | Pre-molding press | Molding press | |

| Force | Ton | 100-200 | 2500-3500 | |

| Max. opening | mm | 2000 | 2400 | |

| Max. stroke | mm | 1600 | 1900 | |

| Working table size | L-R | mm | 3000 | 3500 |

| F-B | mm | 2000 | 2500 | |

| The height from working table to the floor | mm | 0 | 0 | |

| Slider speed | Fast down | Mm/s | 300 | 500 |

| Slow down | Mm/s | 1-20 | 1-40 | |

| Slow return | Mm/s | 5-20 | 1-40 | |

| Fast return | Mm/s | 300 | 500 | |

| Power | KW | 56 | 290 | |

| Four leveling system | / | Including | ||

Products provided by famous enterprises are deeply trusted by users.

PHP(Pengda Hydraulic Press) has been manufacturing hydraulic presses for over 20 years. We specialise in hydraulic press machine development, it's our only product line, and this means we only concentrate in technical innovations and making better energy-saving and more precise cutting presses. As Custom HP-RTM RTM Servo Molding Press Manufacturers and High Pressure RTM Servo Composite Hydraulic Press Factory, PHP(Pengda Hydraulic Press) Presses are present in industry sectors such as Automotive, Rail Transport, Construction, Aerospace and Car Trim. Contact us for more information about PHP(Pengda Hydraulic Press) and our presses.

VIEW MORE

2026/01/30

2026/01/30

2026/01/22

2026/01/22

2026/01/21

2026/01/21

2026/01/15

2026/01/15

2026/01/01

2026/01/01

In the evolving landscape of industrial production, the demand for precision, efficiency, and versatility has never been higher. Among the technological solutions addressing these needs, the servo molding press stands out as a pivotal innovation.

A servo molding press is an advanced type of hydraulic press that integrates servo motor technology to achieve precise control over pressure, speed, and position. Unlike conventional hydraulic presses, which rely on constant pump-driven hydraulic flow, servo presses offer adaptive energy consumption, allowing the machine to adjust power output in real-time according to the molding requirements. This not only enhances operational efficiency but also significantly reduces energy costs.

Key characteristics of servo molding presses include:

These features make HP-RTM servo molding presses particularly attractive for industries that require high precision, complex geometries, and stringent quality standards.

Servo molding presses are highly versatile, serving both non-metallic and composite material applications. Wuxi PengdaHZ Intelligent Equipment Co., Ltd. has developed a research and development project aimed at optimizing these machines for two main categories of applications:

These presses are designed for high-performance composite molding processes such as SMC (Sheet Molding Compound), LFT-D (Long Fiber Thermoplastics – Direct), GMT (Glass Mat Thermoplastics), HP-RTM (High-Pressure Resin Transfer Molding), STM (Structural Thermoplastic Molding), and carbon fiber high-temperature applications.

Industries benefiting from this technology include:

Servo interior presses focus on automotive interior components, providing precise molding, compounding, punching, and heating solutions. Applications include:

By integrating servo technology, these presses ensure consistent quality and efficiency across high-volume automotive production lines.

The adoption of HP-RTM servo molding presses introduces several transformative benefits to manufacturing operations:

These advantages translate directly into cost savings, improved product quality, and higher throughput, aligning with global trends toward sustainable and efficient industrial production.

PHP (Pengda Hydraulic Press) specializes in designing energy-saving hydraulic presses that meet the needs of modern manufacturing. Through continuous innovation, PHP develops fully automated production lines that integrate pressing, heating, and compounding processes into a streamlined workflow. This approach provides:

By focusing on non-metallic materials and advanced composites, PHP addresses industry challenges, such as energy efficiency, material waste reduction, and process optimization.

The continued evolution of HP-RTM servo molding presses is shaped by several key trends:

These trends highlight how servo molding presses are not only keeping pace with modern industry demands but actively shaping the future of high-precision manufacturing.

So, what makes a HP-RTM servo molding press an essential asset for contemporary production lines? It is the combination of precision, efficiency, versatility, and reliability that redefines traditional hydraulic press capabilities. Wuxi PengdaHZ Intelligent Equipment Co., Ltd. fully demonstrates how to combine advanced servo technology with industry experience to provide comprehensive solutions for non-metallic and composite materials.

From automotive interiors to aerospace composites, the servo molding press offers a platform for sustainable, high-quality, and cost-efficient manufacturing. By embracing this technology, manufacturers are not only optimizing their current operations but also preparing for a future where innovation, energy efficiency, and automation define industrial excellence.