Content

- 1 Introduction: What is the HP-RTM Hydraulic Press?

- 2 HP-RTM Hydraulic Press in Composite Molding Applications

- 3 HP-RTM Hydraulic Press in Automotive Manufacturing

- 4 Maintenance Tips for HP-RTM Hydraulic Press

- 5 HP-RTM Hydraulic Press for Small Manufacturers

- 6 Energy Efficiency Solutions in HP-RTM Hydraulic Press

- 7 Conclusion: The Versatility and Future of HP-RTM Hydraulic Press

- 8 FAQs

- 8.1 1. What are the main benefits of using an HP-RTM hydraulic press?

- 8.2 2. How does HP-RTM technology compare to traditional molding methods?

- 8.3 3. Is HP-RTM suitable for small-scale manufacturing?

- 8.4 4. How can energy efficiency be improved in HP-RTM hydraulic presses?

- 8.5 5. What industries benefit most from HP-RTM hydraulic presses?

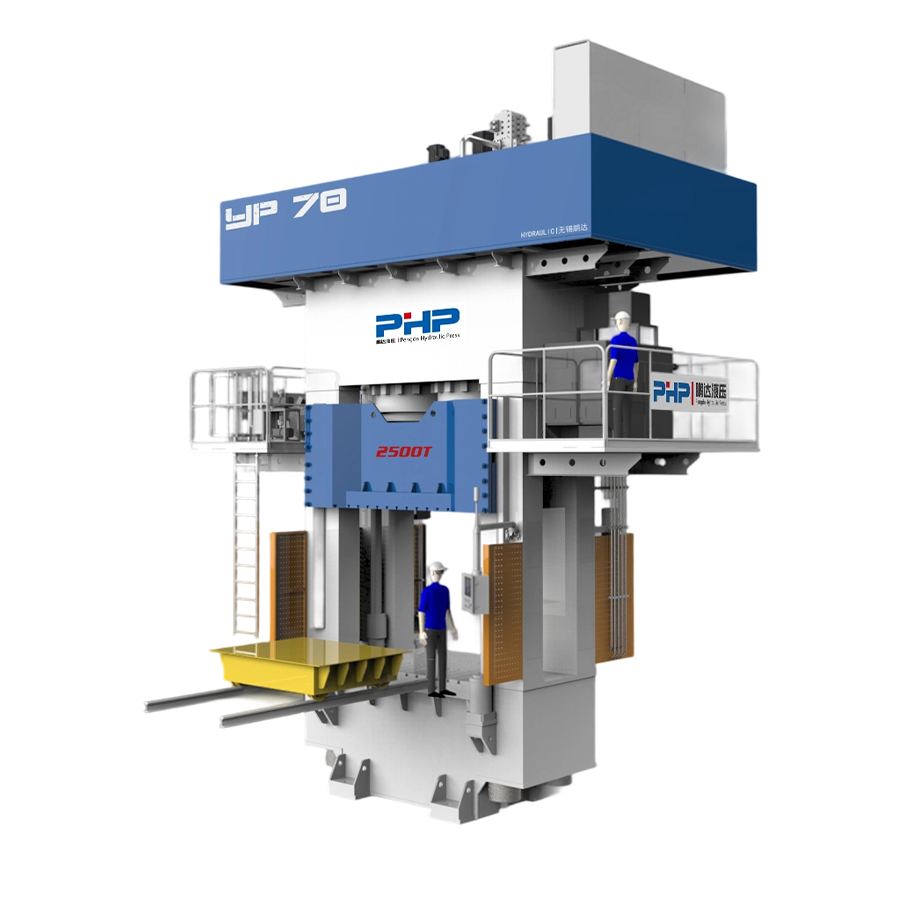

Introduction: What is the HP-RTM Hydraulic Press?

The HP-RTM hydraulic press is a key tool in modern manufacturing, widely used for high-pressure resin transfer molding (RTM) processes. By precisely controlling pressure and temperature, it facilitates the production of high-quality composite materials. Its versatility makes it applicable across various industries, including automotive, aerospace, and renewable energy.

HP-RTM Hydraulic Press in Composite Molding Applications

Understanding Composite Molding

Composite molding refers to the process of creating materials from two or more constituent materials that, when combined, produce a product with different characteristics. The HP-RTM hydraulic press for composite molding is widely used to create lightweight, durable, and high-performance components. The hydraulic press ensures uniform pressure and temperature, resulting in consistent material properties and high-quality finished products.

Advantages of HP-RTM in Composite Molding

- Precision in pressure and temperature control

- Increased strength-to-weight ratio of the finished product

- Enhanced surface quality and reduced porosity

Industry Applications

In industries like aerospace and wind energy, HP-RTM hydraulic presses are used to manufacture components such as turbine blades, fuselage panels, and wing structures. The technology is preferred because it can handle high-performance composite materials like carbon fiber and glass fiber, essential for industries demanding high strength and low weight.

Comparison Table: Traditional Molding vs. HP-RTM Molding

| Traditional Molding | HP-RTM Molding |

| Lower material precision | High precision in material properties |

| Limited control over pressure/temperature | Precise control over both pressure and temperature |

| Higher porosity | Lower porosity, higher surface quality |

HP-RTM Hydraulic Press in Automotive Manufacturing

Automotive Industry’s Need for Lightweight Materials

In the automotive industry, reducing vehicle weight is a key factor in improving fuel efficiency and performance. The best HP-RTM hydraulic press for automotive industry applications is utilized to produce lightweight yet strong parts such as body panels, bumper systems, and interior components. This is achieved through the use of composite materials, which are lightweight but provide high strength, crucial for vehicle safety and fuel economy.

Key Advantages for Automotive Manufacturers

- Improved fuel efficiency due to reduced vehicle weight

- High production efficiency and fast cycle times

- Ability to produce complex geometries and parts

Case Study: Automotive Industry Adoption

Numerous automotive manufacturers have integrated HP-RTM hydraulic presses into their production lines. The ability to mass-produce lightweight composite components quickly has made it a game-changer for the automotive sector.

Maintenance Tips for HP-RTM Hydraulic Press

To ensure the longevity and efficiency of HP-RTM hydraulic press systems, regular maintenance is crucial. Maintenance involves inspecting critical systems such as the hydraulic, electrical, and temperature control systems.

Maintenance Procedures

- Regularly check hydraulic fluid levels and replace them when necessary

- Inspect the temperature control system to ensure consistent performance

- Test pressure gauges and sensors for accuracy

Common Issues and Troubleshooting

Some common issues that may arise include inconsistent pressure distribution, wear and tear on hydraulic seals, and temperature fluctuations. Implementing routine checks and immediate repairs can prevent costly downtime and increase the system’s lifespan.

Comparison Table: Well-Maintained vs. Poorly Maintained Presses

| Well-Maintained Press | Poorly Maintained Press |

| Longer operational life | Frequent downtime and repairs |

| Consistent performance | Inconsistent output and quality |

| Fewer operational issues | Higher risk of breakdowns |

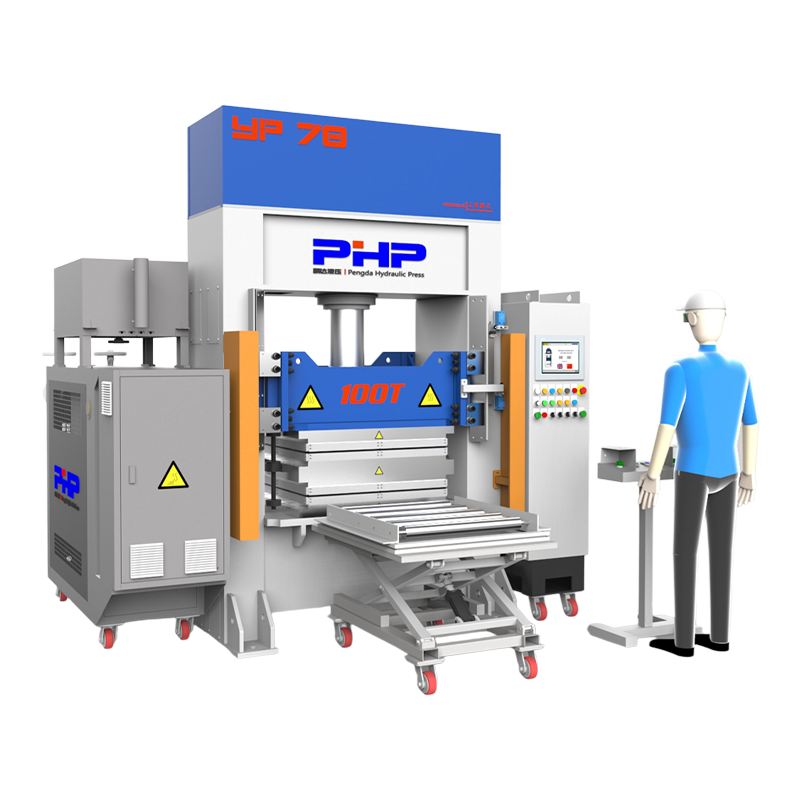

HP-RTM Hydraulic Press for Small Manufacturers

Small manufacturers often face budget constraints when selecting equipment, but the affordable HP-RTM hydraulic press for small manufacturers offers an economical solution. These presses are designed to deliver the necessary precision and power while maintaining cost-effectiveness.

Considerations for Small Manufacturers

- Size and capacity: Small presses are ideal for limited production runs

- Energy efficiency: Low operational costs are important for small operations

- Space constraints: Compact models save valuable floor space

Case Study: A Small Manufacturer’s Success

In a recent case, a small composite manufacturer adopted a compact HP-RTM press, reducing their production costs by 20% while maintaining high-quality outputs for their automotive parts.

Energy Efficiency Solutions in HP-RTM Hydraulic Press

With increasing focus on sustainability, energy efficiency is a significant concern. The HP-RTM hydraulic press energy efficiency solutions are designed to minimize energy consumption while maintaining optimal performance.

Energy-Efficient Design Features

- Optimized hydraulic systems to reduce energy loss

- Advanced heating and cooling technologies to minimize energy waste

- Energy-efficient motors and variable speed drives

Benefits of Energy Efficiency

By implementing energy-efficient solutions, manufacturers can significantly reduce operational costs and meet environmental standards. Additionally, these solutions contribute to a lower carbon footprint, which is increasingly important for companies aiming to adopt sustainable practices.

Comparison Table: Traditional Hydraulic Press vs. Energy-Efficient HP-RTM Press

| Traditional Hydraulic Press | Energy-Efficient HP-RTM Press |

| Higher energy consumption | Lower energy consumption |

| No temperature optimization | Optimized heating and cooling systems |

| Less environmentally friendly | More sustainable and eco-friendly |

Conclusion: The Versatility and Future of HP-RTM Hydraulic Press

The HP-RTM hydraulic press offers a versatile solution to manufacturers across various industries. Its applications span from aerospace to automotive and renewable energy, providing significant benefits in terms of precision, cost-effectiveness, and sustainability. As the industry continues to evolve, future advancements in automation, energy efficiency, and smart technology will further enhance the capabilities of HP-RTM presses.

How to Choose the Right HP-RTM Hydraulic Press?

- Consider the production volume and part complexity

- Look for energy-efficient models to reduce long-term operational costs

- Evaluate the availability of maintenance support and service

FAQs

1. What are the main benefits of using an HP-RTM hydraulic press?

HP-RTM presses provide precision, consistent product quality, and reduced production times, making them ideal for industries that require high-performance materials, such as aerospace and automotive.

2. How does HP-RTM technology compare to traditional molding methods?

HP-RTM technology offers better control over pressure and temperature, resulting in higher-quality composite materials with fewer defects and lower porosity compared to traditional molding methods.

3. Is HP-RTM suitable for small-scale manufacturing?

Yes, small manufacturers can benefit from affordable and compact HP-RTM presses, which offer precise control at a lower cost, making them ideal for limited production runs.

4. How can energy efficiency be improved in HP-RTM hydraulic presses?

Energy efficiency can be improved by adopting optimized hydraulic systems, energy-efficient motors, and advanced heating/cooling systems that minimize energy consumption.

5. What industries benefit most from HP-RTM hydraulic presses?

Industries such as aerospace, automotive, and wind energy benefit greatly from HP-RTM hydraulic presses due to the high precision, material quality, and production efficiency they offer.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский