When it comes to selecting a thermoplastic press for your production line, there are multiple critical factors to consider. Whether you're producing small batches, large-scale components, or high-precision items, the choice of equipment directly impacts production efficiency, cost-effectiveness, and product quality. In this article, we will explore the key aspects that should guide your decision-making process, helping you make an informed choice tailored to your manufacturing needs.

Content

1. Key Factors to Consider When Choosing a Thermoplastic Press

1.1 Production Scale and Demand

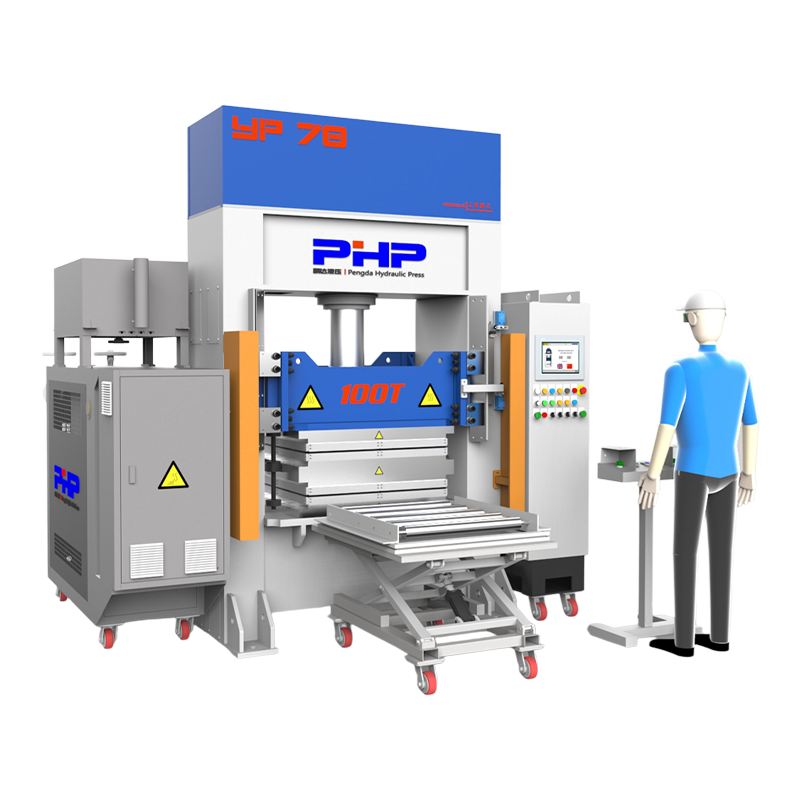

The scale of your manufacturing operation plays a vital role in determining which type of thermoplastic press will best meet your needs. Small manufacturers, for example, may prioritize cost-effectiveness and flexibility, while larger operations may need a press with higher throughput and automation capabilities. For small manufacturers, it’s essential to select equipment that balances initial cost and long-term benefits.

- Best thermoplastic press for small manufacturers – Typically, these machines are compact, cost-efficient, and versatile for limited production runs.

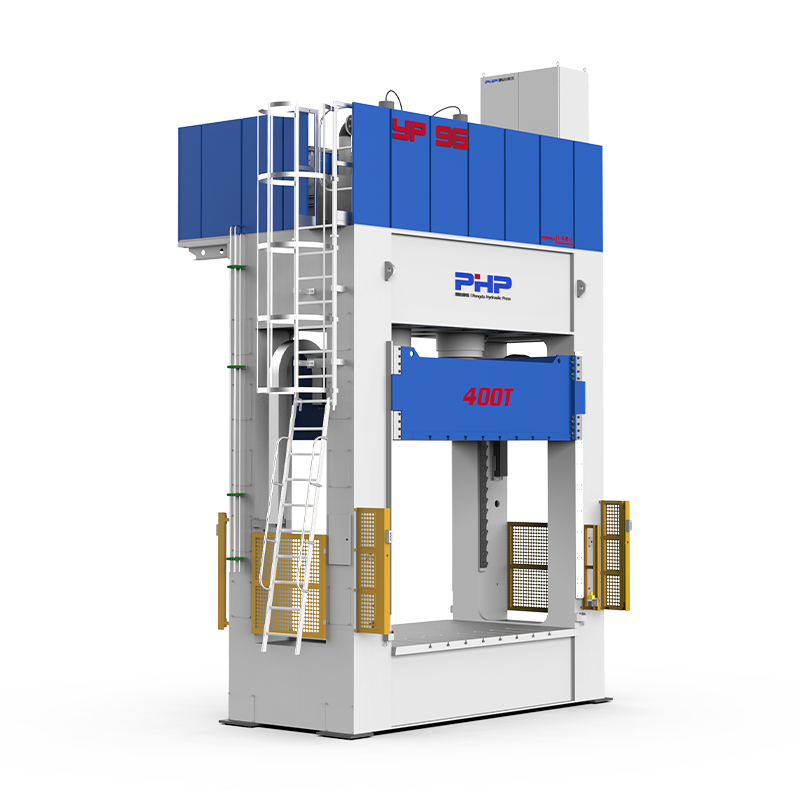

- Thermoplastic press for high-volume production – Requires larger presses with automated systems to maximize output and reduce labor costs.

Here’s a quick comparison between small-scale and large-scale production needs:

| Scale | Small Manufacturers | Large Manufacturers |

| Production Volume | Low to Medium | High |

| Machine Size | Compact | Large |

| Cost Considerations | Lower Initial Cost | Higher Initial Cost |

1.2 Automation and Control Systems

As manufacturing technology continues to evolve, the role of automation in thermoplastic pressing becomes increasingly important. Automated presses help improve efficiency by reducing manual intervention, ensuring consistent quality, and minimizing errors. For complex materials such as composites, an automated thermoplastic press can provide the precision required to meet stringent production standards.

- Automated thermoplastic press for composite materials – Perfect for industries needing precision molding and high-volume output.

- Manual versus automated systems – Automated systems offer increased speed and reduced operator error, but manual systems may be suitable for smaller batches or more flexible processes.

1.3 Maintenance and Longevity

Choosing a thermoplastic press with low maintenance needs is essential to keeping your operation running smoothly. Overlooking maintenance requirements can lead to frequent breakdowns, expensive repairs, and extended downtime. When selecting your press, consider factors such as ease of access for repairs, availability of spare parts, and the overall durability of the equipment.

- How to maintain a thermoplastic press machine – Regular maintenance, proper lubrication, and monitoring of wear-and-tear parts can extend the life of your press.

1.4 Material Compatibility and Flexibility

The material compatibility of your thermoplastic press is another critical factor. Different presses are designed to handle specific types of thermoplastic materials. If you are working with a variety of materials, choosing a machine that is adaptable and offers versatility will be beneficial in the long term. Additionally, different thermoplastic presses may offer unique features such as temperature control or adjustable pressure to ensure optimal material processing.

- Compatibility with different polymers and composite materials is crucial for diverse manufacturing needs.

- Flexible presses can handle various materials like PVC, PE, PP, and custom composites.

1.5 Precision and Product Quality

Maintaining high precision is crucial when using a thermoplastic press. The consistency of temperature, pressure, and timing directly affects the quality of your molded parts. For complex or high-performance applications, precision becomes even more critical. In some cases, you may need to consider alternative methods like injection molding for intricate parts that require fine tolerances.

- Thermoplastic press vs injection molding – Injection molding may be more suitable for high-precision, intricate parts due to its ability to achieve fine details with minimal shrinkage.

- However, thermoplastic pressing offers advantages such as lower tooling costs and quicker setup times for certain product types.

| Process | Thermoplastic Press | Injection Molding |

| Material Flexibility | Good | Limited |

| Precision | Moderate | High |

| Cost | Lower | Higher |

2. Other Key Considerations

2.1 Cost Efficiency

Cost is a critical factor when selecting a thermoplastic press, particularly for those with a limited budget. Affordable thermoplastic presses for prototyping options are often available for smaller manufacturers or companies that need to produce prototypes or small quantities. These presses are typically more cost-effective and come with flexible configurations, making them ideal for lower-volume production.

2.2 Brand and Supplier Reputation

When selecting a thermoplastic press, it's essential to evaluate the brand and supplier’s reputation in the market. Choose suppliers that offer excellent customer service, warranty options, and spare parts availability. A well-established supplier can offer additional support for installation, maintenance, and troubleshooting, helping you maximize the machine's lifespan.

2.3 Equipment Scalability and Future Upgrades

As your production needs evolve, your press should be scalable and capable of handling increased volumes or upgraded features. Make sure the press you choose can accommodate future upgrades such as enhanced automation or new molding technologies.

3. Common Misconceptions When Choosing a Thermoplastic Press

3.1 Overestimating Low-Cost Machines

While low-cost thermoplastic presses may seem appealing, they often come with trade-offs such as reduced efficiency, limited features, and shorter lifespans. Choosing based solely on price may lead to higher operating costs and maintenance issues down the line.

3.2 Ignoring Maintenance Costs

Ongoing maintenance is an often-overlooked aspect of machine selection. Some presses may require more frequent servicing, leading to increased downtime and repair expenses. It is essential to factor in both initial costs and the long-term expenses of maintaining the equipment.

3.3 Underestimating Automation Benefits

Automated systems are often seen as an unnecessary expense for smaller operations. However, these systems can significantly improve production speed, consistency, and product quality, making them an essential investment for long-term competitiveness.

Conclusion

Choosing the right thermoplastic press is crucial for optimizing production efficiency, reducing operational costs, and ensuring consistent product quality. By considering factors such as production scale, automation, maintenance requirements, material compatibility, and precision, you can make a well-informed decision that will support your manufacturing goals. Whether you're a small business owner or a large-scale manufacturer, understanding these critical factors will help you select the ideal press for your production line.

FAQ

- What is the difference between a thermoplastic press and injection molding? Injection molding provides higher precision for intricate parts, while thermoplastic pressing offers a more cost-effective solution for larger components with less intricate detail.

- How often should I maintain my thermoplastic press? Maintenance frequency depends on the machine's usage, but regular checks every 6 months are recommended to ensure optimal performance and extend the machine's lifespan.

- Can I use a thermoplastic press for multiple materials? Yes, many thermoplastic presses are designed to handle various polymers and composites, making them versatile for different production needs.

- Is automated thermoplastic pressing worth the investment? Automated presses can significantly improve efficiency, reduce errors, and enhance consistency, making them a valuable investment for high-volume production runs.

- What are the benefits of choosing a cost-effective thermoplastic press? Cost-effective presses are ideal for small batches, prototypes, or businesses with budget constraints, offering good flexibility without sacrificing too much on performance.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский