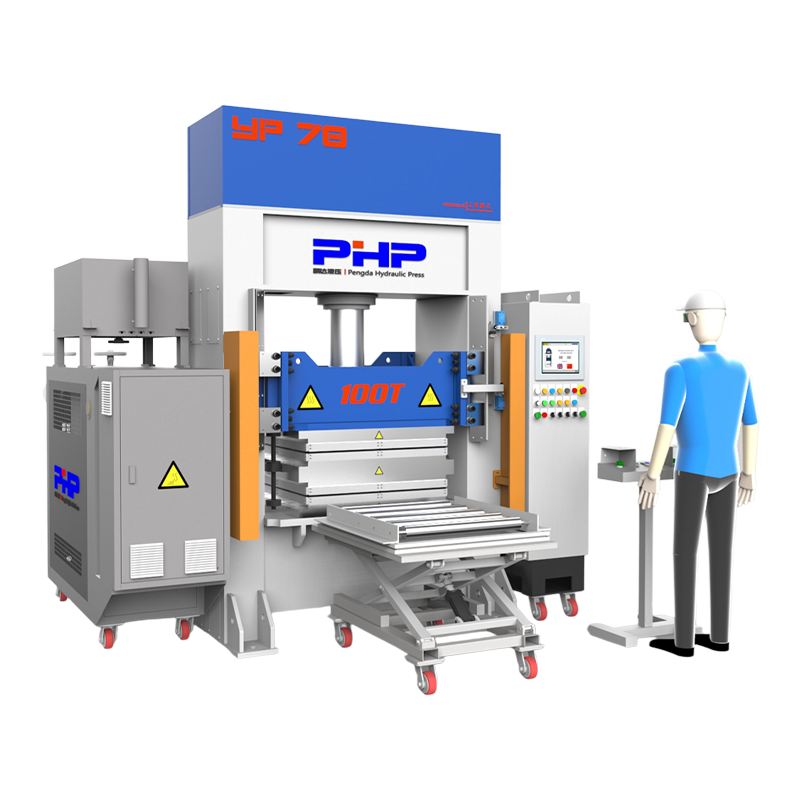

Composite presses play a crucial role in industries that rely on high-performance materials for their manufacturing processes. Optimizing the performance of composite presses can lead to improved production efficiency, cost savings, and enhanced product quality. This article explores how various factors, from temperature control to energy efficiency, impact the overall manufacturing process when composite presses are optimized. It also delves into the specific requirements for different manufacturing scenarios and offers maintenance tips to extend the life of these vital machines.

Content

- 1 1. Performance Factors of Composite Presses

- 2 2. Impact of Performance Optimization on the Manufacturing Process

- 3 3. Optimization Solutions for Different Manufacturing Needs

- 4 4. Maintenance for Long-Term Performance Optimization

- 5 5. How Small Businesses Can Optimize Their Composite Presses

- 6 Conclusion: The Long-Term Benefits of Performance Optimization for Composite Presses

1. Performance Factors of Composite Presses

1.1 Temperature Control

One of the key factors in optimizing composite presses is managing temperature. In applications involving high-temperature materials, precision temperature control ensures the proper curing and bonding of composites. For instance, the use of high-temperature composite presses for high-temperature applications enables manufacturers to work with materials that require stable heat conditions for curing without damaging the material structure.

1.2 Pressure and Forming Time Control

Accurate control over pressure and forming time can significantly affect the density, homogeneity, and strength of composite materials. Optimizing these parameters ensures that the final product maintains consistent structural integrity. The performance optimization of composite presses for small batch production is particularly important when dealing with custom or low-volume orders, where precision is crucial.

1.3 Energy Efficiency and Press Performance

As energy costs rise, energy-efficient composite presses for industrial use have become more critical. These presses are designed to consume less power while maintaining high performance, which helps reduce operational costs and environmental impact. The long-term savings in energy costs are a significant benefit for manufacturers operating in energy-intensive industries.

2. Impact of Performance Optimization on the Manufacturing Process

2.1 Increased Production Efficiency

Optimizing the performance of composite presses can drastically reduce production time and downtime. For instance, an optimized composite press can speed up heating cycles and reduce the need for repairs, both of which lead to higher throughput. In comparison, older or poorly maintained presses might cause delays in production, leading to increased labor costs and wasted material.

| Optimized Press | Non-Optimized Press |

| Faster heating cycles | Slower heating cycles |

| Less downtime | Higher risk of breakdowns |

| Higher throughput | Lower throughput |

2.2 Cost Reduction

Optimizing energy consumption and press performance can reduce material wastage and increase the yield of each production run. For instance, investing in an energy-efficient composite press for industrial use will save money over time, reducing the need for expensive repairs and minimizing the cost of energy consumption.

2.3 Enhanced Product Quality and Consistency

Performance optimization leads to more consistent products with better structural integrity. Precise temperature and pressure control ensure that each composite material is properly bonded, resulting in superior product quality. Manufacturers can also achieve higher repeatability, ensuring that products meet stringent specifications consistently.

3. Optimization Solutions for Different Manufacturing Needs

3.1 Optimization for Small Batch Production

Small-scale manufacturers often require presses that can handle lower production volumes but still offer precision. An optimized composite press for small batch production can help such businesses meet their specific needs, offering quick setup times, flexibility, and high-quality output. These presses are ideal for custom orders and prototyping, where batch size and product variation can be high.

3.2 High-Temperature Applications

For industries dealing with high-performance composites, such as aerospace and automotive manufacturing, the composite press for high-temperature applications plays a crucial role. These presses are specifically designed to handle the intense heat requirements needed to cure high-temperature composites, ensuring that the material properties remain stable during the forming process.

3.3 The Future of Energy-Efficient Composite Presses

Energy-efficient presses are becoming a priority in modern manufacturing due to growing environmental concerns and rising energy costs. By using energy-efficient composite presses for industrial use, manufacturers can minimize their carbon footprint while lowering operational costs, creating a more sustainable production environment.

4. Maintenance for Long-Term Performance Optimization

4.1 Regular Maintenance and Inspections

To maintain the optimized performance of composite presses, regular maintenance is essential. Operators should conduct routine inspections, clean components, and replace worn-out parts. Failing to maintain the press can result in performance degradation, increased downtime, and higher repair costs.

4.2 Workflow and Operation Optimization

Training operators to follow the best practices for press operation is essential for performance optimization. Proper workflow management, including consistent monitoring of pressure and temperature, ensures that the press is used efficiently and product quality is maintained over time. Regular operator training can prevent operational mistakes and ensure the press works at its full potential.

5. How Small Businesses Can Optimize Their Composite Presses

Small businesses often work with limited budgets, making the choice of an affordable yet efficient composite press for small businesses crucial. By focusing on essential features like energy efficiency, precision, and ease of maintenance, small manufacturers can achieve performance optimization without overextending their financial resources. Investing in high-quality machines that offer long-term value is key to staying competitive in the market.

Conclusion: The Long-Term Benefits of Performance Optimization for Composite Presses

Performance optimization of composite presses is essential for manufacturers who aim to increase production efficiency, reduce costs, and maintain high product quality. By focusing on temperature control, pressure regulation, and energy efficiency, manufacturers can ensure that their presses are operating at peak performance, resulting in better products and a more profitable manufacturing process.

FAQs

- What are composite presses used for? Composite presses are used to shape and cure composite materials in industries such as automotive, aerospace, and manufacturing.

- How can I improve the efficiency of my composite press? Regular maintenance, optimizing temperature control, and investing in energy-efficient models are all key to improving press efficiency.

- What is the importance of energy efficiency in composite presses? Energy-efficient composite presses reduce operational costs, lower energy consumption, and contribute to sustainability efforts in manufacturing.

- What is the role of pressure control in composite press optimization? Precise pressure control ensures that the composite material is evenly formed, leading to stronger and more consistent products.

- How can small businesses afford composite presses? Small businesses can invest in affordable composite presses for small batch production that balance cost and performance, optimizing production without heavy investment.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский