With the deepening application of composite materials in new energy vehicles, battery systems, rail transit, construction machinery, and aerospace, industry requirements for forming equipment are evolving. Companies are increasingly concerned not only with press tonnage and specifications but also with equipment stability, safety, energy efficiency, and compatibility with production processes. Hydraulic presses are transforming from “single-function pressing machines” to “systematic forming equipment.”

PHP has long focused on the R&D and manufacturing of composite material hydraulic presses. Through extensive practical projects, the company has continuously optimized equipment structure and system configuration, forming systematic advantages in energy efficiency, safety, stability, maintenance convenience, and space utilization. The presses can meet various composite material forming processes, including SMC, HP-RTM, LFT-D, and GMT.

Content

I Energy-Saving Design Advantages

In the context of rising energy costs in manufacturing, the energy efficiency of hydraulic equipment has become a key concern. By continuously optimizing the drive method and control system, PHP presses effectively reduce energy consumption while maintaining performance.

Servo electro-hydraulic system saving 30–60% energy

The servo drive outputs power as needed, automatically reducing energy consumption during standby or low-load conditions, avoiding the waste caused by traditional hydraulic systems running at high power continuously. Meanwhile, the servo system offers faster response and higher control precision, reducing overall operational costs without compromising production efficiency.

The application of energy-saving systems can significantly lower long-term electricity costs and enhance production line sustainability and competitiveness.

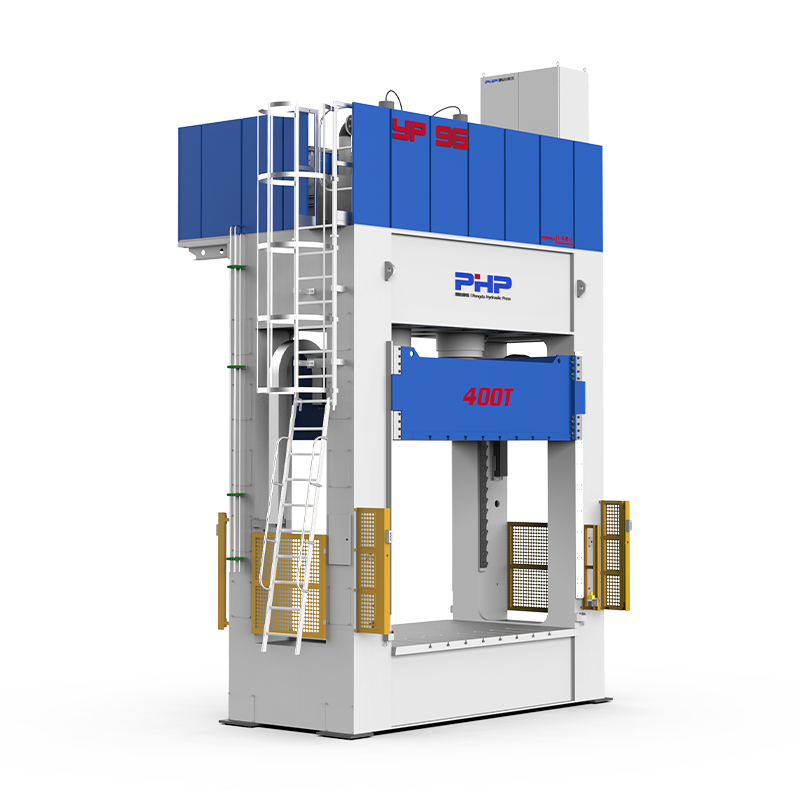

II Safety System Advantages

Composite material forming involves high tonnage and pressure, with complex safety risks. Therefore, safety design must run through the entire structure, hydraulic system, and control system. PHP places safety design as a fundamental part of equipment development.

Multiple safety protection devices

Equipped with safety locking mechanisms, emergency stop switches, light curtains, hydraulic safety circuits, safety relays, ladders, and alarm systems, forming a comprehensive safety protection system to reduce operational risks and ensure stable operation.

Upgradable to European CE standards for enhanced safety

For export projects and high-standard applications, equipment can be fitted with safety PLCs, SITEMA locking devices, cylinder safety valves, laser scanners, and explosion-proof chains, meeting international safety norms and high-end market requirements.

Through systematic safety design, the equipment not only meets production requirements but also provides reliable protection for operators.

III Hydraulic Pipeline Reliability Advantages

The stability of hydraulic systems largely depends on the quality of pipeline manufacturing and installation. PHP has established strict standards in pipeline design and processing to ensure reliable system operation.

- Galvanized cold-drawn pipes for enhanced stability: high strength and corrosion resistance extend service life.

- Industrial dust-removal grinding table for pipe cutting and cleaning: prevents iron filings from entering the hydraulic system.

- CNC machining center for chamfering, bending, and connections: ensures dimensional accuracy and assembly consistency.

- Flared connection technology replacing traditional welded pipes: reduces leakage risk and simplifies maintenance.

- Metal ferrule and SAE flange connections instead of rubber seals: higher pressure and temperature resistance for long-term reliability.

- Laser marking linking each pipe to hydraulic diagrams: enables fast identification and maintenance.

Refined pipeline manufacturing not only enhances overall hydraulic system stability but also reduces failures caused by contamination, leakage, or assembly errors. Standardized material selection, CNC processing, and precise assembly allow the system to maintain stable pressure and response over long-term operation, reduce maintenance frequency, lower downtime risk, improve line efficiency, and extend equipment service life.

IV Equipment Stability Advantages

Stability directly affects composite product quality and is a key indicator of hydraulic press performance. PHP synchronously controls design and manufacturing to ensure stable operation under high loads.

- Stable operation with minimal vibration: structural optimization and matched hydraulic control ensure smooth operation for high-precision forming.

- High-strength structural design and inspection system: finite element analysis during design and marble flat ruler inspection during manufacturing ensure machine precision.

Stability ensures consistent dimensions and batch quality of composite products. Optimized structure, precision control, and assembly inspection enable high-rigidity, low-vibration performance even under high-tonnage operation, improving product yield, reducing mold wear, and making the equipment suitable for high-demand, continuous production environments.

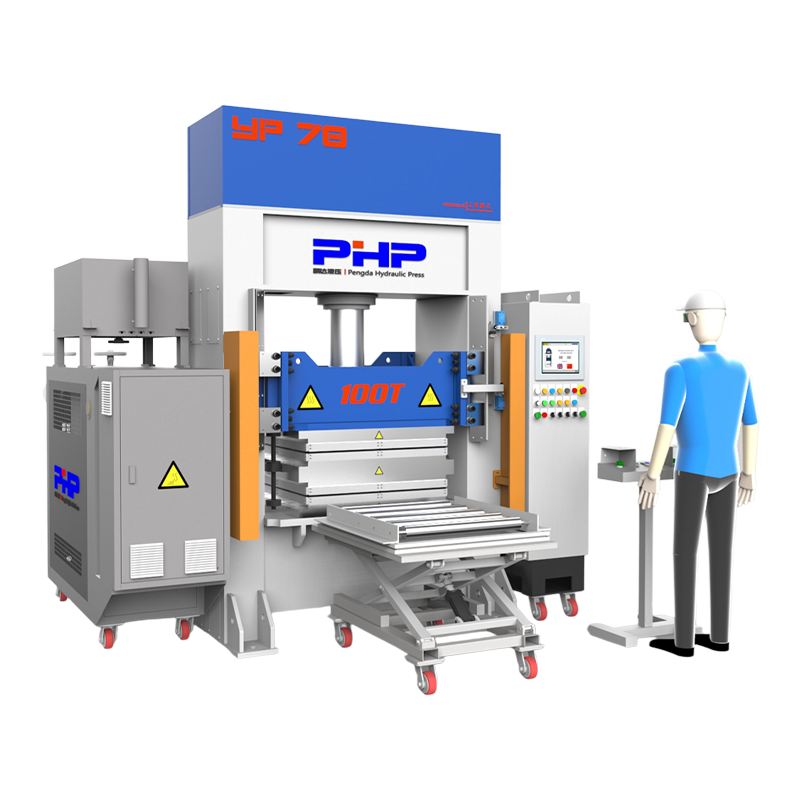

V Space Utilization Advantages

In modern factories, equipment footprint directly affects line layout and investment costs. PHP improves space utilization through vertical design.

- Two-layer platform for auxiliary equipment: mold temperature controllers, vacuum systems, and other auxiliaries can be centrally arranged on the second layer, enhancing line integration.

- Hydraulic station and electrical cabinets positioned above: reduces floor space, ideal for space-limited environments.

The vertical and integrated design reduces footprint, improves layout flexibility, shortens pipeline and cable paths, enhances system response, and provides space for future expansion or process upgrades, optimizing overall factory efficiency and lowering infrastructure costs.

VI Operational Convenience Advantages

As automation increases, ease of operation becomes critical. PHP incorporates multiple intelligent functions into the control system.

- One-touch filtration: automatically cycles and filters hydraulic oil, reducing manual maintenance.

- One-touch pressure release: quickly releases high pressure via touchscreen, improving mold change efficiency.

- One-touch backflush: recovers heat transfer oil from molds, reducing waste.

Intelligent operations shift equipment from “experience-based” to “process-standardized,” allowing operators to perform maintenance and adjustments via touchscreen, improving efficiency, reducing human error, shortening downtime, and enhancing overall production line performance.

VII Functional Expansion and Process Adaptability

Different composite processes have diverse requirements. Equipment expandability is a key competitive advantage. PHP offers multiple optional systems to meet varying production needs.

- Four-corner leveling system: improves forming precision for thin-walled parts.

- Mold temperature heating system: maintains stable forming temperatures.

- Vacuum system: enhances product density and quality.

- Environmental system: meets modern manufacturing environmental and safety standards.

Modular design allows flexible configuration to meet different product and process requirements, maintaining high adaptability and scalability. This expandability increases equipment value and provides a reliable foundation for future process upgrades and capacity expansion.

Competition in composite presses has shifted from tonnage and specifications to system capabilities and overall performance. Through continuous optimization in energy-saving design, safety, pipeline reliability, structural stability, and intelligent control, PHP presses achieve higher reliability and adaptability in practical production environments.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский