The importance of sMC molding press in the field of composite material production is self-evident. A high-quality hydraulic press can significantly improve production efficiency and product quality, creating higher value for enterprises. But facing the dazzling array of products in the market, how to choose suitable equipment has become a challenge for many enterprises. This article will provide you with practical selection guidelines from key perspectives such as product quality, process requirements, and intelligent use.

1. Product quality: Only with a solid foundation can we achieve great success

Product quality is the core element for measuring the quality of SMC frame servo composite hydraulic press.

*Striving for excellence in material selection

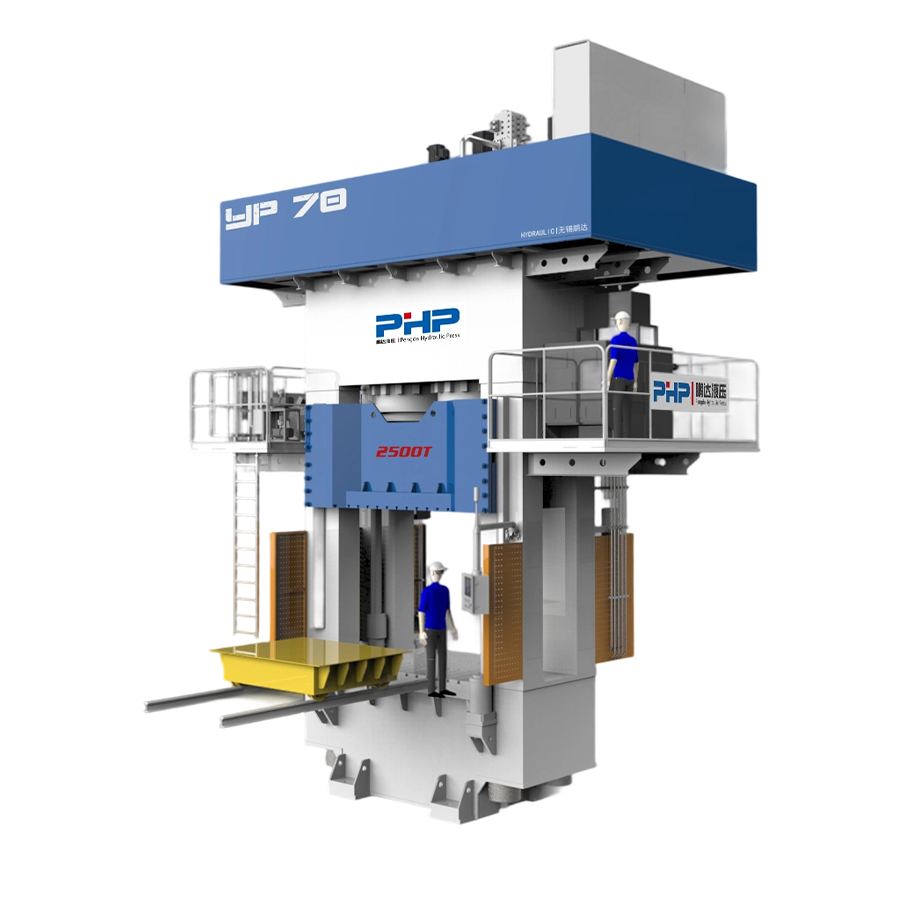

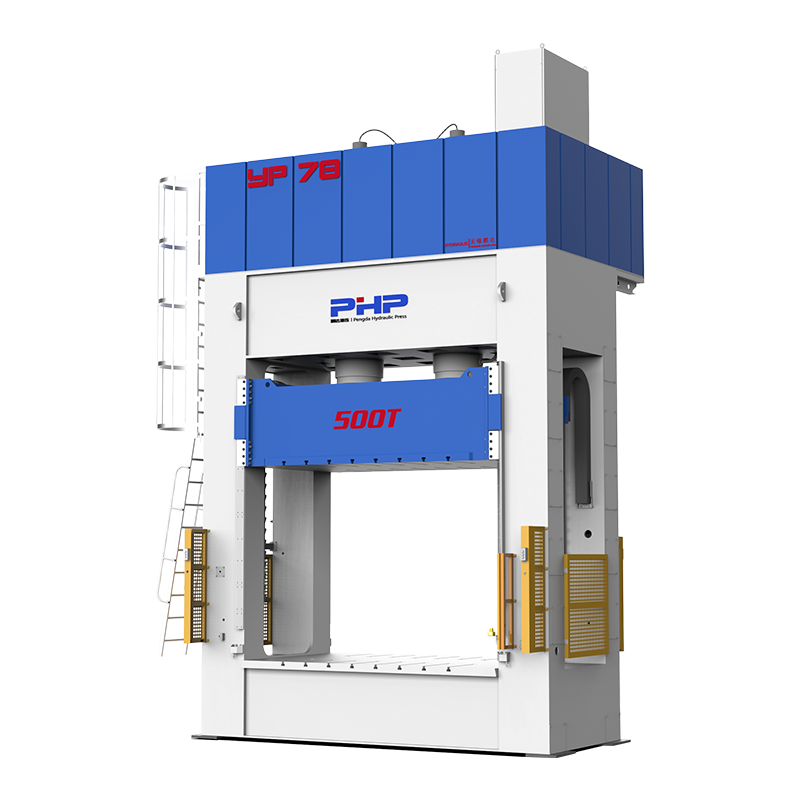

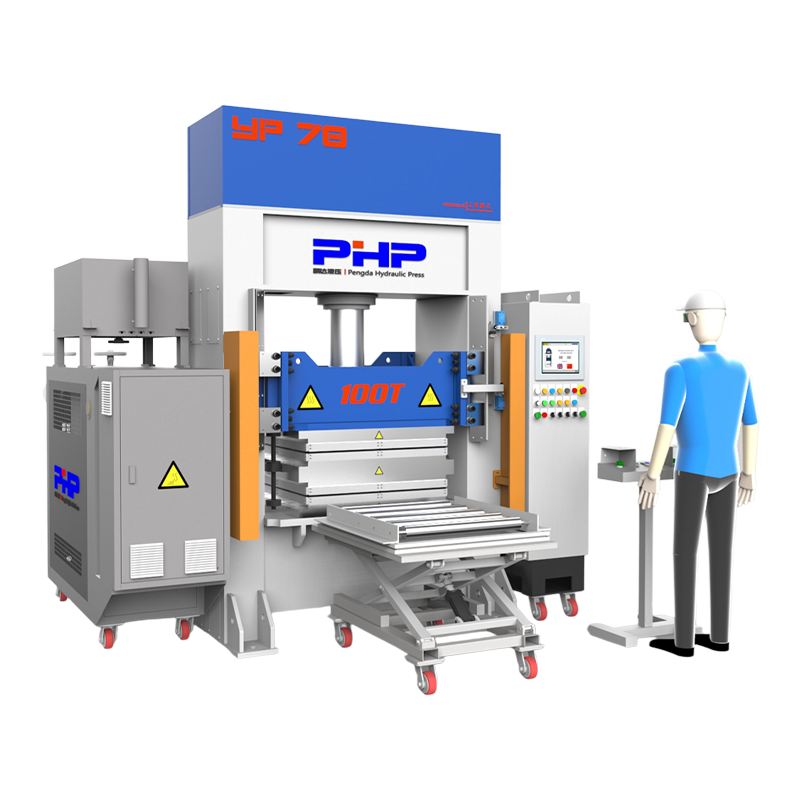

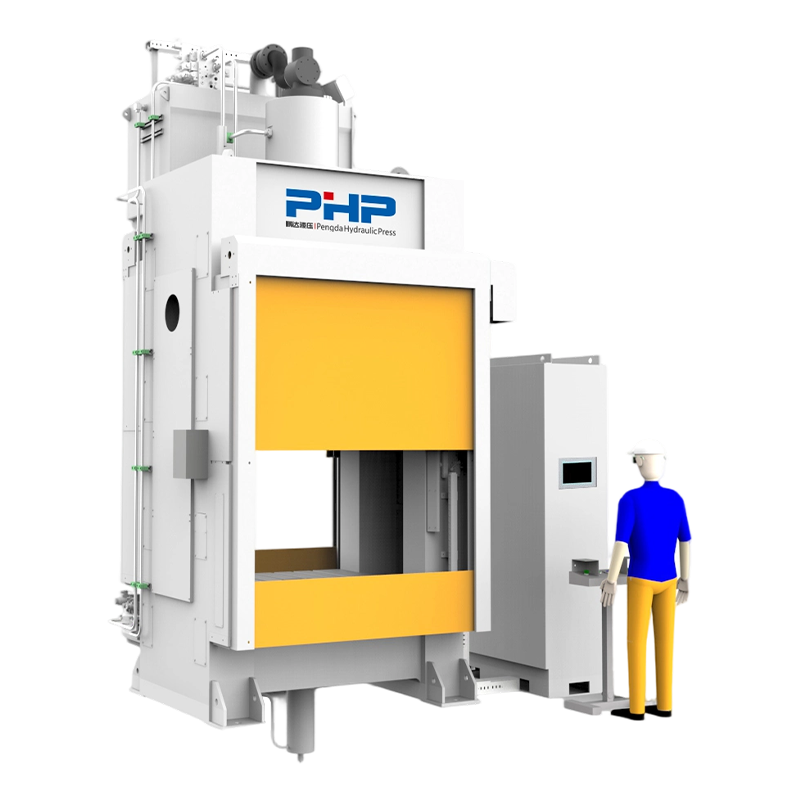

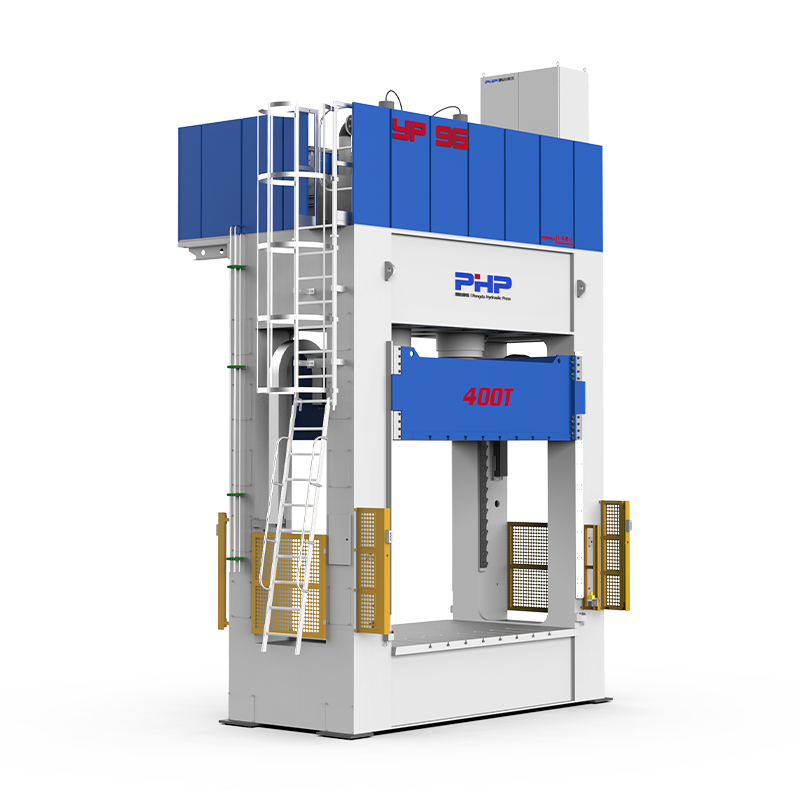

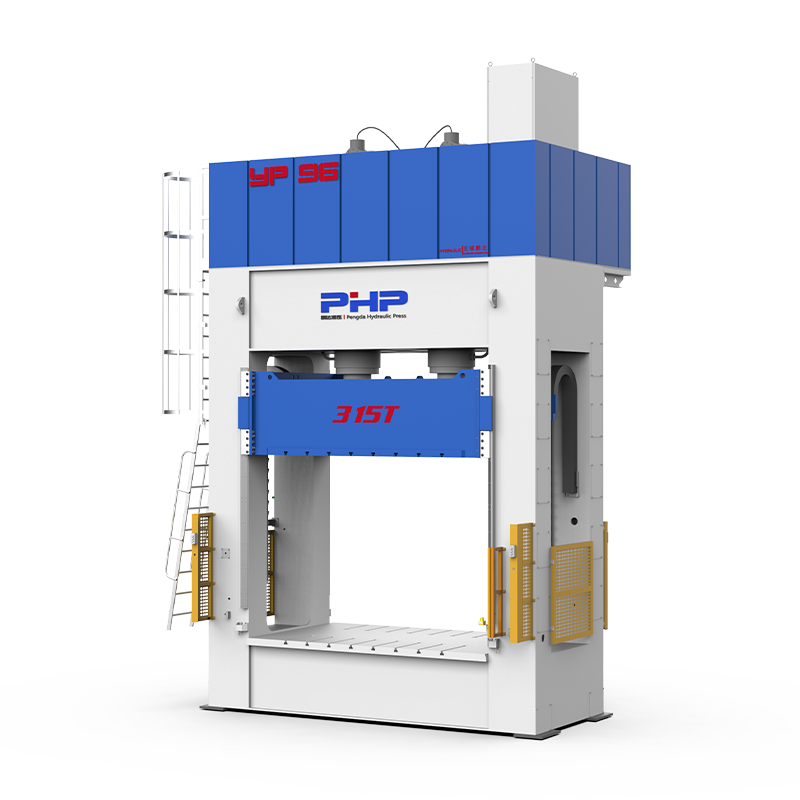

The body frame of the equipment often adopts welding technology and undergoes effective heat treatment to ensure structural stability, which can withstand long-term and high-intensity working pressure without deformation. The frame type SMC press designed and manufactured by Wuxi Pengda adopts Q345 steel plate for the body, and the internal rib plate layout meets the stress requirements. The maximum stiffness of the equipment can reach 1/6000.

*Ensure the quality of key components

Wuxi Pengda's hydraulic press uses servo motors with a positioning accuracy of ± O.1mm, and the accompanying imported hydraulic pump effectively ensures the stable operation of the equipment.

*Strict quality inspection process

Every qualified hydraulic press should undergo multiple testing processes, including pressure testing, stroke accuracy testing, electrical safety testing, etc., to ensure that all performance indicators meet national standards and industry requirements.

2.Process requirements: precise matching to enhance efficiency

Different composite material processing techniques have specific requirements for hydraulic presses.

*Stable pressure.

Wuxi Pengda's SMC molding machine adopts advanced servo oil electric control technology, which can achieve precise pressure setting. The pressure fluctuation range should be controlled within ± 3%, effectively ensuring the dimensional accuracy and physical properties of SMC molded products.

*Accurate temperature control system

Wuxi Pengda's press can usually be equipped with a dual temperature integrated molding machine, which controls the temperature of the upper and lower plates of the mold heating plate separately, and the temperature deviation usually does not exceed + 5 °C.

*Fast lifting speed

At the same time, in order to meet the processing requirements of composite materials with different thicknesses, the worktable stroke of the hydraulic press should be flexibly adjustable and have a fast lifting speed to improve production efficiency.

3.Using Intelligence: Empowered by Technology, Leading the Future

With the arrival of the Industry 4.0 era, intelligence has become an important development trend for SMC frame servo composite hydraulic presses. Intelligent hydraulic presses can achieve remote monitoring and operation. Through loT technology, operators can use their mobile phones or computers to monitor the operating status of the equipment anytime and anywhere, including parameters such as pressure, temperature, and stroke, and promptly detect and handle potential faults.

The automated production function is also a major highlight of intelligent hydraulic presses. It can automatically complete a series of processes such as material feeding, pressing, holding, and demolding based on preset process parameters, greatly reducing manual intervention and improving production efficiency and product consistency.

In summary, when choosing an SMC frame servo composite hydraulic press, enterprises need to comprehensively consider multiple aspects such as product quality, process requirements, and intelligent use. Only by choosing high-quality and intelligent hydraulic presses that meet their own needs can enterprises stand undefeated in fierce market competition and achieve sustainable development.

English

English 中文简体

中文简体