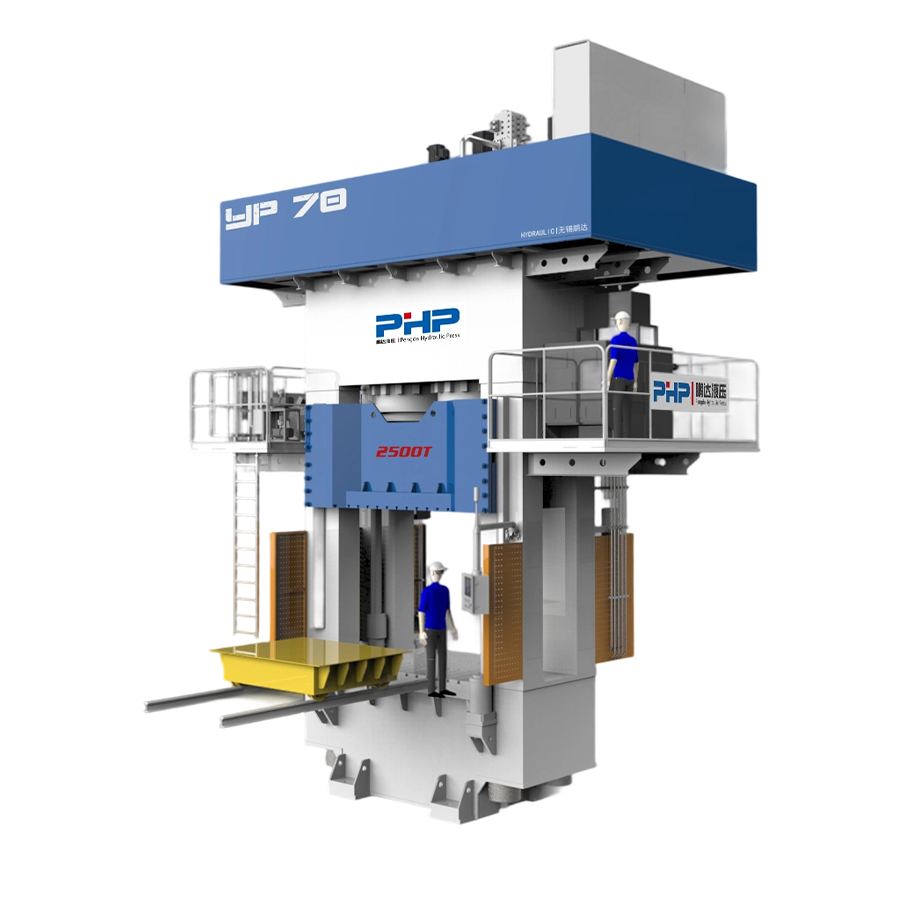

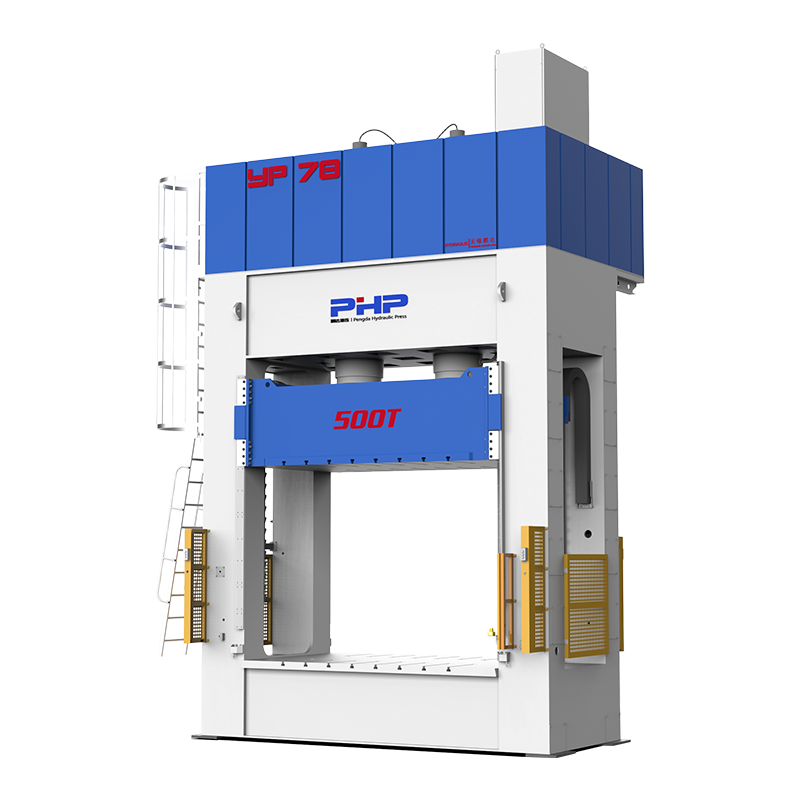

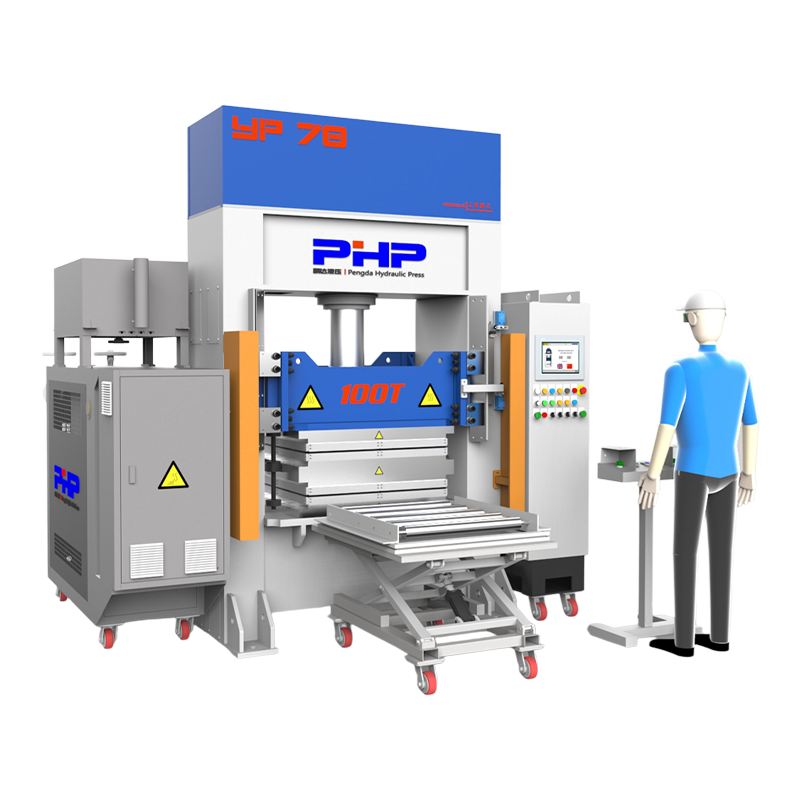

In the design of hydraulic presses, the selection of the slide guide system directly affects the performance, accuracy and service life of the equipment. Currently, the market prefers frame presses rather than four-column presses. One of the main reasons is that the guide rails used by frame presses can keep the press stable for a long time during operation, and its performance far exceeds that of traditional four-column presses that use guide sleeves sliding along the columns.

1.Guiding Accuracy

The guide rail design has a significant advantage in guiding accuracy. This design achieves precision control through precise adjustment of the push-pull screws on the slider. The slider can maintain extremely high straightness during the up and down movement. Precision is the real advantage of the guide rail. Only the screws need to be adjusted to achieve precision control. The straight sliding design of the column has a small contact area and usually only has a few linear contact points, resulting in reduced guiding accuracy. After long-term use, wear will further aggravate the loss of accuracy.

2. Convenience of Adjustment

The design of the guide rail adjustment system is user-friendly. Operators can operate the screws to achieve precision adjustment when the equipment is fully assembled, without disassembling any major components, which greatly simplifies the debugging process.

In contrast, the column straight sliding structure has a large adjustment workload, and often requires the top structure of the hydraulic press to be disassembled to access the adjustment mechanism, which is time-consuming and labor-intensive.

3. Service Life

The surface of the guide rail is hardened or coated, and has outstanding wear resistance; the inclined surface structure can also disperse wear and extend the service life.

In actual cases, the service life of the 45° inclined guide rail under normal use and maintenance conditions generally exceeds 10 years.

The service life bottleneck of the column direct sliding system is obvious. As the main structure of the machine body, once the guide surface is severely worn, the entire machine tool must be overhauled, and it is difficult to restore the original accuracy after repair. Statistics show that the column direct sliding hydraulic press needs to repair the column every 5-7 years on average.

4. Economic Comparison

Although the initial manufacturing cost of the guide rail is high, the full life cycle cost is significantly lower. Even if the guide rail surface is worn, only the guide rail bar needs to be replaced, and the maintenance cost is low. The downtime is short. The accuracy retention is good, the product qualification rate is high, and the quality loss is reduced.

The column direct sliding system seems to have a low initial investment, but the subsequent maintenance cost is amazing. Each overhaul requires the disassembly of a large number of parts and the downtime is long. The waste loss caused by the decrease in accuracy cannot be ignored. What's more serious is that as the equipment ages, many users have to eliminate equipment that has not been completely worn out in advance without continuous maintenance.

Cnoclusion

Comparing the two designs, the rail guide outperforms the straight column slide guide in every important way. It is accurate, easy to adjust, lasts longer, and requires less maintenance. That’s why it’s the preferred choice for modern hydraulic presses. Of course, the old straight column design, while simpler, lacks in key ways—it’s less accurate, wears faster, and requires constant adjustment. Today, if you want reliability and performance without the headaches, rail guides are the only choice.

English

English 中文简体

中文简体