The successful development of the full carbon fiber composite material and the large-size car body load-bearing structure has verified the feasibility of the carbon fiber composite material used in the rail transit load-bearing structure.

However, the application of carbon fiber composite materials in rail vehicles is still in its infancy, and it is still limited by cost, materials, design, process, etc.

Especially the cost problem is a strong barrier restricting its promotion and application.

The continuous and rapid development of carbon fiber technology and the application of rail transit composite car bodies must be promoted from the following aspects.

1. In-depth development of basic research on carbon fiber materials

2. Carry out research on the structural design of carbon fiber composite materials

3. Strengthen the optimization research of the composite material structure forming process

4. Establish a composite material standard system suitable for the rail transit industry

5. Improve carbon fiber production capacity and level

The promotion and application of carbon fiber in the body of rail transit vehicles is a major opportunity and challenge for the composite material industry.

Although currently constrained by manufacturing costs, molding processes, and production efficiency, it is difficult to achieve mass production in the short term, but with new Materials and new technologies are advancing with each passing day.

It is believed that in the near future, China will usher in another revolution in the application of new materials for rail vehicle bodywork.

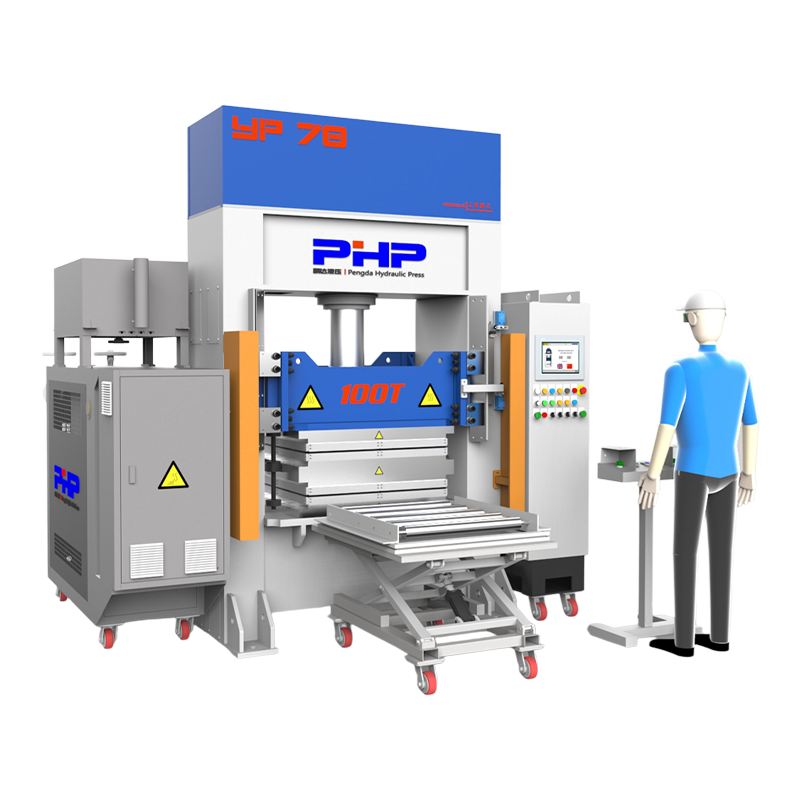

PHP(Pengda Hydraulic Press) is a manufacturer of various large, medium, and small hydraulic presses based on the green industry and advocating technological innovation. Independently developed and designed servo hydraulic system hydraulic machine, used for thermosetting and thermoplastic products such as SMC, BMC, GMT, LFT-D parts and products in the fields of automobiles, railways, aerospace, sports goods, building materials/building, and electronics/electricity Press molding process. It effectively solves the shortcomings of traditional presses, such as high energy consumption and large vibration, and popularizes new types of presses that save energy and electricity, reduce oil leakage, and operate smoothly.

If you have any questions, please call +86 0510 83394311 or send an email to cindy@wuxipd. com.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский