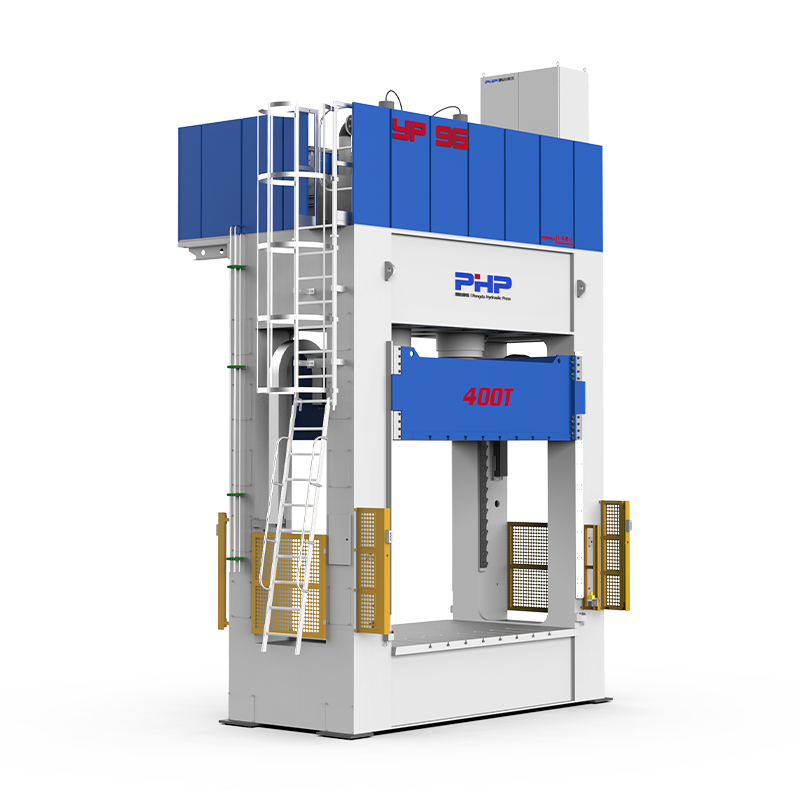

The maintenance of hydraulic molding press is very important. Proper maintenance can ensure stable operation of the equipment and extend its service life. Due to the involvement of various technical requirements such as mechanical, hydraulic, electrical, etc., there are many standards and contents for the maintenance of hydraulic presses. But in simple terms, the following basic requirements need to be achieved:

1. Keep the appearance clean

2. Observe the exposed electronic components every day for any damage, regularly open the electrical cabinet to clean the dust, and observe if there are any broken wires or connectors

3. If oil leakage is found, investigate the cause and replace the seals or joints immediately If there is a malfunction during machine operation, replace the backup valve. If there is a malfunction in the hydraulic pump that causes the press to fail to operate, choose the order of repair before replacement

4. Check the hydraulic oil monthly for discoloration, turbidity, blackness, or excessive impurities, and replace it directly, including replacing the filter element at the inlet of the oil tank

5. Check whether the screws and nuts are loose every quarter or every six months, and tighten them if they are loose.

PHP(Pengda Hydraulic Press) adheres to the principles of "pragmatism, enterprising, and integrity", sincerely faces every customer, earnestly and timely solves every customer's problem, and continuously develops and pursues technological innovation, striving to provide more and better products and services for new and old foreign users! Welcome to contact us: [email protected], Phone: 56 0510-83394311

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский