In modern industrial manufacturing, composite materials, due to their lightweight, high strength, and excellent corrosion resistance, have become essential materials in aerospace, automotive, energy, and sporting goods industries. One of the key aspects of achieving high-quality composite material products is the application of composite presses. With the development of materials science and the continuous advancement of manufacturing processes, composite press technology is undergoing profound changes. Its performance and level of intelligence directly determine the quality, production efficiency, and cost-effectiveness of composite products.

Content

- 1 The Core Principle of Composite Presses

- 2 Technological Innovation and Intelligent Development

- 3 Material Adaptability and Process Diversity

- 4 Safety and Environmental Performance

- 5 Application Prospects and Industry Trends

- 6 FAQ (Frequently Asked Questions)

- 6.1 Q1: Are composite presses suitable for all types of composite materials?

- 6.2 Q3: What are the main advantages of intelligent presses?

- 6.3 Q3: What contributions do composite material presses make to environmental protection?

- 6.4 Q4: What are the future development trends for composite material presses?

The Core Principle of Composite Presses

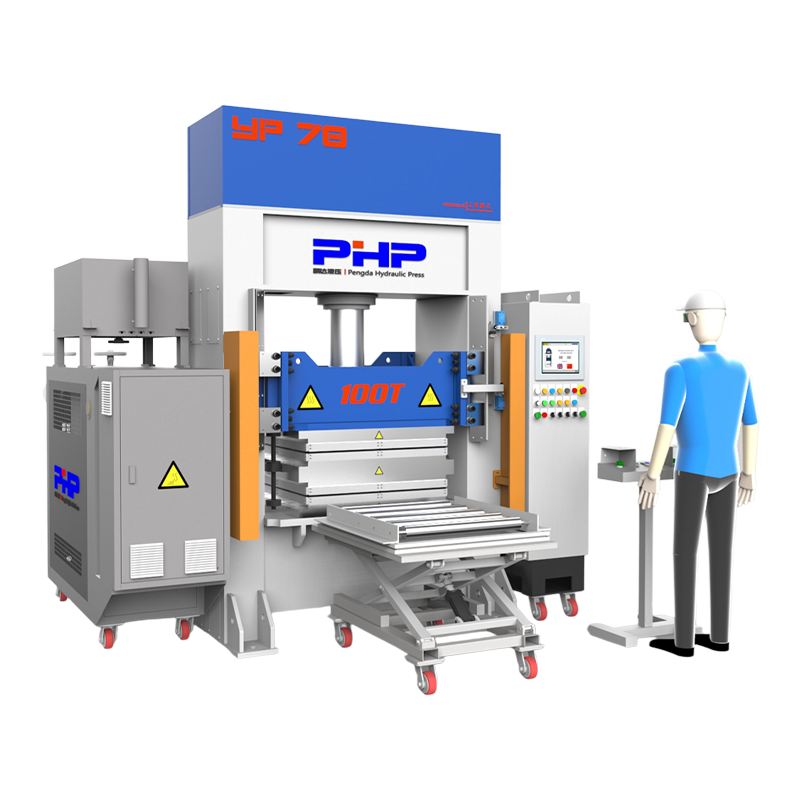

The core working principle of composite presses is to fully solidify and bond the resin matrix and reinforcing fiber materials through controlled heating and pressurization, thereby forming a high-performance composite material structure. During the molding process, precise control of temperature, pressure, and time is required. These three factors interact and directly affect the internal structure and mechanical properties of the material. Especially in high-performance aerospace materials, even minor process deviations can lead to a decline in material performance; therefore, precise control is the core of composite press design.

Modern composite presses typically employ closed-loop hot pressing systems combined with high-rigidity mechanical structures, capable of withstanding high-temperature and high-pressure environments while ensuring uniform pressure distribution. This uniformity is particularly critical for thick-walled or complex composite parts, as any localized stress concentration can lead to delamination, bubbles, or uneven resin flow. The press achieves full-process management of the molding process through precise temperature control of the mold and heating plate, as well as closed-loop control of the hydraulic system.

Technological Innovation and Intelligent Development

Composite presses are continuously upgrading towards intelligent technology. Modern composite presses are not merely simple heating and pressurizing devices, but high-end equipment integrating sensors, data acquisition systems, and intelligent control algorithms. By monitoring pressure, temperature, and deformation data in real time, the system can dynamically optimize the molding curve, ensuring consistent performance for every product.

Intelligent presses also enable remote monitoring and process parameter recording, providing reliable data support for quality tracking and process improvement during production. In aerospace and high-end automotive manufacturing, this traceability is a crucial prerequisite for ensuring material safety and reliability. The development of intelligent presses not only improves production efficiency but also reduces human intervention and operational risks, making composite material manufacturing more efficient and precise.

Material Adaptability and Process Diversity

Another significant advantage of composite presses lies in their adaptability to various composite material systems. From traditional carbon fiber reinforced resins to high-performance thermosetting or thermoplastic composites, modern presses can meet the thermal and mechanical requirements of diverse materials. This versatility allows manufacturers to produce composite parts with varying performance levels and structural complexities on the same equipment, thereby improving equipment utilization and economic efficiency.

In actual production, the thickness of composite parts, fiber layup orientation, and die shape all pose challenges to press performance. High-end composite presses achieve precise molding of complex structures through modular design, adjustable dies, and multi-zone temperature control technology. This flexibility not only expands the application range of composite materials but also drives the development of new lightweight structures.

Safety and Environmental Performance

Composite presses operate under high temperature and pressure environments, making their safety design crucial. Modern equipment incorporates stringent safety redundancy designs in hydraulic systems, temperature control systems, and mechanical structures, ensuring automatic shutdown in abnormal situations to protect operators and die safety. Simultaneously, with increasingly stringent environmental regulations, composite material manufacturers require equipment with energy-saving and low-emission characteristics. The new generation of composite presses achieves a balance between environmental protection and performance by optimizing heating efficiency, recovering waste heat, and reducing energy waste.

Application Prospects and Industry Trends

The rapid growth of the composite materials market has placed higher demands on composite presses. From large airframe structures in aerospace to lightweight bodies in new energy vehicles, and even high-performance sporting goods, composite materials are widely replacing traditional metal materials. Efficient, intelligent, and reliable composite presses are the core support for this trend. In the future, with the development of material innovation and automation technology, composite presses will further evolve towards higher speed, higher precision, and full-process digitalization.

The industry's demand for modular and scalable equipment is also increasing. This means that future presses must not only meet the high-performance requirements of a single process but also be able to flexibly handle diverse production tasks, thereby enhancing the overall competitiveness of the manufacturing system.

FAQ (Frequently Asked Questions)

Q1: Are composite presses suitable for all types of composite materials?

A1: Modern presses are very versatile in terms of material adaptability, but specific performance depends on the equipment's temperature control range, pressure rating, and mold design. Some high-temperature, high-performance composite materials may require specialized equipment or special modifications.

Q3: What are the main advantages of intelligent presses?

A2: Intelligent presses can monitor process parameters in real time, automatically optimize molding curves, and record data for traceability. This significantly improves product consistency and production efficiency while reducing operational risks.

Q3: What contributions do composite material presses make to environmental protection?

A3: Modern equipment achieves energy conservation and environmental protection goals by improving heating efficiency, recovering waste heat, and reducing energy consumption, while also reducing potential exhaust emissions and resource waste during production.

Q4: What are the future development trends for composite material presses?

A4: Future developments will see further intelligentization, digitalization, and modularization, achieving high speed, high precision, and low energy consumption, while adapting to the production needs of various materials and complex structures.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский