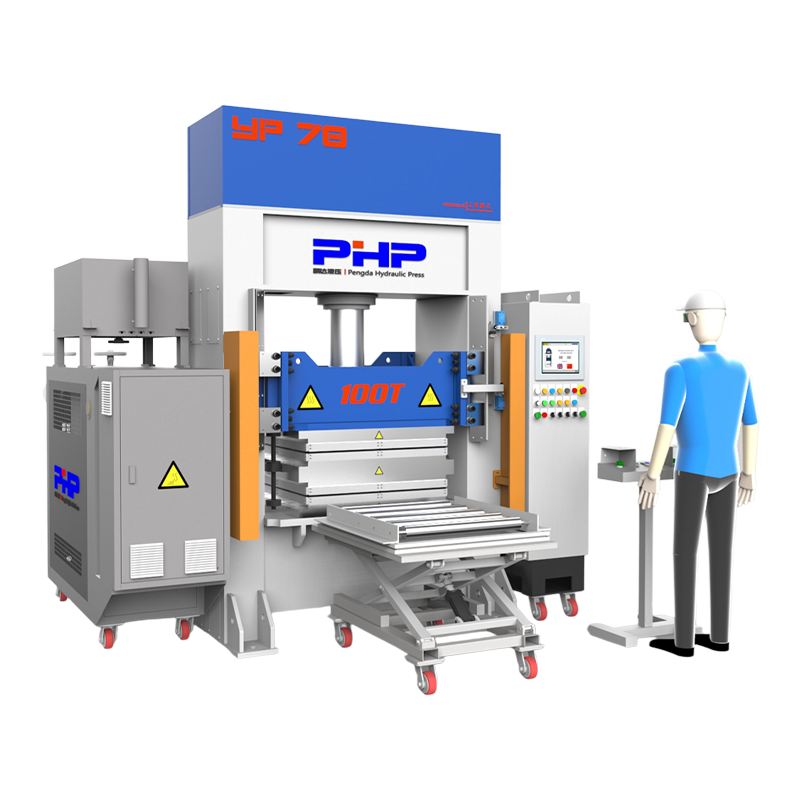

In modern industrial production, hydraulic presses have become indispensable core equipment, and GMT hydraulic presses, with their advanced technology and stable performance, are gradually becoming the first choice for various manufacturing enterprises. Whether in metal forming, composite material processing, or industrial production processes requiring high precision, GMT hydraulic presses have demonstrated outstanding capabilities.

The essence of hydraulic technology is to transfer energy through the incompressibility of liquids to achieve highly efficient mechanical operations. Compared to traditional machinery, GMT hydraulic presses can complete high-intensity, high-precision forming tasks in a shorter time, while also offering significant advantages in energy consumption control and operational safety. Its powerful pressure regulation system and intelligent control unit allow the equipment to adapt to the requirements of different materials and processes, thereby significantly improving production efficiency and product quality.

Content

- 1 High-Precision Control System: The Intelligent Brain of the Hydraulic Press

- 2 Multi-functional Applications: From Metal Forming to Composite Material Processing

- 3 Reliability and Safety: Guardians of Industrial Production

- 4 Energy Saving and Environmental Protection: A New Trend in Green Industry

- 5 FAQ

High-Precision Control System: The Intelligent Brain of the Hydraulic Press

One of the core competitive advantages of GMT hydraulic presses lies in their high-precision control system. This system not only precisely adjusts pressure and stroke but also monitors changes in hydraulic oil temperature, flow, and pressure in real time, ensuring stable performance during long-term operation. Through advanced sensors and control algorithms, operators can easily adjust complex process parameters, significantly reducing error rates in the production process.

The GMT hydraulic press utilizes a digital control platform, enabling seamless integration with modern industrial production lines for remote monitoring and intelligent management. This functionality not only enhances operational convenience but also provides strong support for enterprises' Industry 4.0 initiatives.

Multi-functional Applications: From Metal Forming to Composite Material Processing

The GMT hydraulic press demonstrates exceptional adaptability in its application range. In metal processing, it can perform deep stamping, forming, and pressing of steel, aluminum, and other alloy materials. In composite material processing, it can precisely control pressure and temperature to achieve high-quality forming results. Whether processing thin sheet materials or thick structural components, the GMT hydraulic press maintains high dimensional consistency and perfect surface flatness.

This versatility not only saves enterprises on equipment investment costs but also enhances production line flexibility. By adjusting the hydraulic press's pressure curve and stroke mode, different process requirements can be completed on the same machine, greatly simplifying the production process.

Reliability and Safety: Guardians of Industrial Production

In industrial production environments, the reliability and safety of equipment directly impact a company's production efficiency and economic benefits. GMT hydraulic presses are designed with long-term operational stability in mind. Their hydraulic systems utilize high-quality materials and advanced manufacturing processes to ensure excellent performance even under high loads. Furthermore, the equipment features comprehensive safety protection mechanisms, including overpressure protection, overtemperature alarms, and emergency shutdown functions, providing complete protection for operators.

Beyond the hardware safety design, GMT hydraulic presses also prioritize safety in their software control system. An intelligent alarm system promptly alerts operators to abnormal conditions, helping them quickly locate problems and take corrective action, minimizing equipment failures and production downtime.

Energy Saving and Environmental Protection: A New Trend in Green Industry

Against the backdrop of global industrial energy conservation and emission reduction, GMT hydraulic presses achieve significant energy savings through optimized hydraulic system design and energy management. Their hydraulic oil circulation system is precisely controlled, reducing energy loss and environmental impact. Through an intelligent control system, the equipment automatically adjusts its operating status based on actual load, avoiding unnecessary energy waste. This not only meets the environmental requirements of enterprises but also aligns with modern industry's pursuit of sustainable development.

GMT hydraulic presses feature noise control and vibration reduction designs, minimizing interference with the production environment during operation and improving the overall quality of the factory's working environment.

FAQ

Which industrial fields are suitable for GMT hydraulic presses?

GMT hydraulic presses are suitable for metal forming, composite material processing, and high-precision industrial manufacturing, meeting diverse production process requirements.

Is the equipment complex to operate?

GMT hydraulic presses are equipped with an advanced digital control system with an intuitive user interface that supports remote monitoring and parameter adjustment, reducing operational complexity.

Are energy consumption and maintenance costs high?

Due to its energy-saving design and intelligent control system, GMT hydraulic presses have relatively low energy consumption, and the equipment is easy to maintain, effectively reducing production costs.

How is safety guaranteed?

GMT hydraulic presses have comprehensive safety protection mechanisms, including overpressure protection, temperature alarms, and emergency shutdown functions, and are equipped with an intelligent monitoring system to ensure long-term safe operation.

What are the future technological development directions?

GMT hydraulic presses will develop towards deep integration of intelligence, automation, and the Industrial Internet, achieving production optimization and data-driven intelligent management.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский