SMC (Sheet Molding Compound)

Suitable for mass production of products that require high surface quality and weather resistance, are cost-sensitive, and do not demand extreme structural strength or lightweight properties. Its advantages include stable molding performance, good surface finish, and mature automation. However, it is relatively heavy, with limited mechanical properties (compared with continuous fiber composites) and dimensional accuracy.

HP-RTM (High-Pressure Resin Transfer Molding)

Suitable for structural components requiring high stiffness/strength, lightweight design, and fiber continuity, or when the strength-to-weight ratio is a key factor in manufacturing. Its advantages include high specific strength of the final product and the ability to produce thin-walled, large-span structural parts. The disadvantages are complex processes, high costs for molds, tooling, and materials, and stringent process control requirements. Cycle time and productivity are limited by the curing system.

1. Material difference

|

|

SMC |

HP-RTM |

|

Compose |

Chopped fibers (mainly glass fibers) + polyester or unsaturated resin matrix + fillers/flame retardants/accelerators + reinforcing modifiers. The material is supplied in sheet form (pre-mixed compound). |

The intervention immersed fabric (unidirectional fabric, woven fabric, laminated fabric, continuous fiber preform)+low viscosity liquid resin (epoxy/unsaturated polyester/styrene substitute, etc.) is injected and cured under high pressure. |

|

Fiber properties |

Chopped or randomly oriented fibers, with no continuous fiber reinforcement - performance is balanced in all directions (isotropic), but the specific strength and stiffness are lower than those of continuous fiber composites. |

Continuous fibers (glass, carbon, or hybrid), with configurable orientations, offering excellent mechanical properties, especially along the fiber direction. |

|

Formula advantage |

Easily flame-retardant (typically achieving UL94 V-0 rating or meeting automotive flame-retardant standards), with good weather resistance and dimensional stability. |

Can achieve high glass or carbon fiber volume fractions (high strength, high stiffness, lightweight), with selectable resin systems to enhance thermal stability, adhesion, and flame retardancy (though flame- retardant modifications may be more complex and costly). |

|

Surface and post-treatment |

Provides a smooth surface easily suitable for painting and coating. |

Attention must be paid to mold surface and resin penetration control; post-processing is usually required to achieve high surface quality. |

2. Final Product Quality

|

|

SMC |

HP-RTM |

|

Mechanical Properties |

Tensile and shear strengths are moderate, making it suitable for components subject to uniform loads or for non-primary load-bearing covers. Impact resistance is average, though chopped fibers offer some energy absorption advantage. |

Along the fiber direction, strength and stiffness can be much higher than SMC; fatigue resistance and crack resistance are superior, making it suitable for load-bearing structures or components subjected to high-impact or torsional forces. |

|

Dimensional Accuracy and Stability |

Formed by pressing, with good dimensional stability; however, tolerances for thickness and small geometric features are influenced by material flow and mold design. |

High requirements for thickness and local fill control; if injection and venting are well-designed, high dimensional accuracy can be achieved, but resin shrinkage also requires precise control and compensation. |

|

Surface Quality / Appearance |

Can achieve a smooth surface directly, suitable for aesthetic requirements of exposed covers, with good paint adhesion. |

Directly formed surfaces may require post-treatment (varnish, polishing, coating, or film) to achieve the same level of appearance as SMC; But common mode gelcoat or membrane technology can also be used to improve the appearance, which increases the cost. |

3. Press and Auxiliary Equipment

SMC requires relatively low equipment investment and is technologically mature and stable. Typically, SMC processing only requires a press, a set of molds, and a heating system to produce parts. The functional requirements for the press are not high. Raw materials can be purchased directly in sheet form and weighed and cut using an SMC cutting machine. After molding, the finished parts only require sanding.

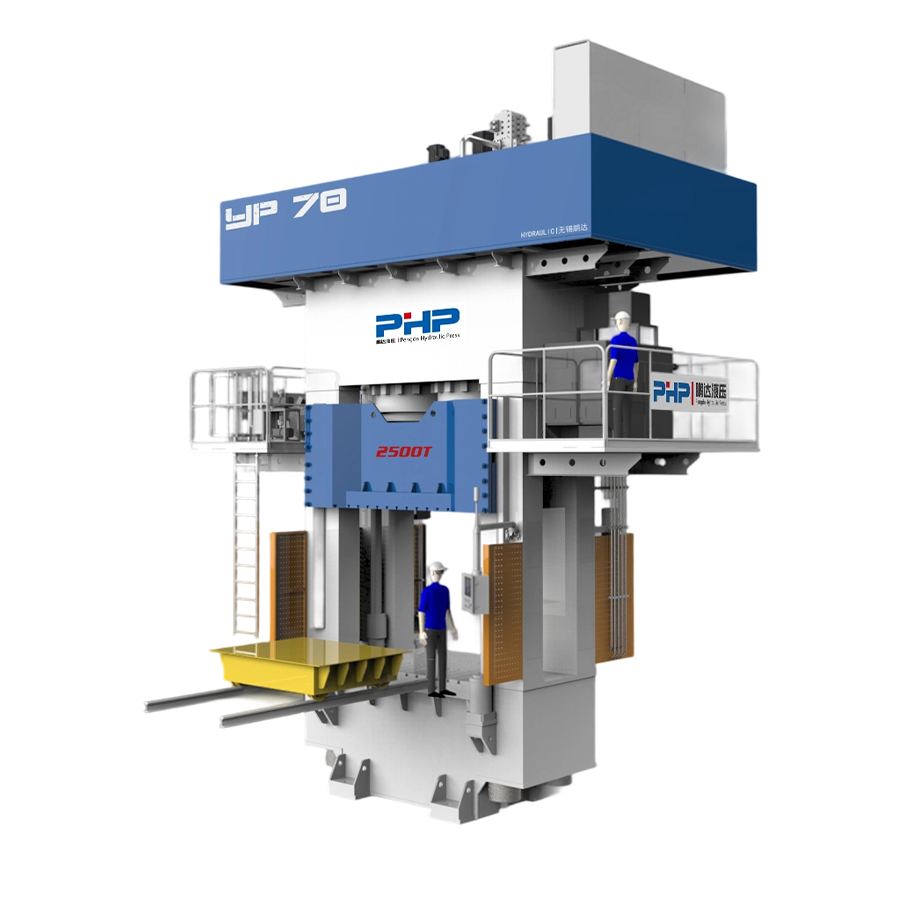

HP-RTM requires a higher equipment investment. Typically, the material must first be preheated and preformed, then undergo high-pressure injection molding in a large-tonnage press, and finally be trimmed and cut using a laser cutter. The entire process - from raw material to finished product - requires equipment including: a 100–200-ton preforming press (with heating system), a 2500 - 3500 ton molding press (with heating system, vacuum system, and four-corner leveling function), two sets of molds, cutting machine, resin injection machine, cooling and curing fixtures, laser cutter, and airtightness tester. The upfront investment is substantial.

4. Others

Maintenance and Recyclability: Both SMC and HP-RTM are thermosetting systems, making recycling difficult.

Lightweighting: HP-RTM (especially when using carbon fiber) can significantly reduce weight compared to SMC. When applied to battery housings, it can improve vehicle range or reduce overall battery costs.

Supply Chain / Availability Risk: The supply chain for chopped fiber SMC is generally stable; carbon fibers and high-performance resins can experience significant price fluctuations during tight supply, requiring evaluation of long-term supply stability.

Process Flexibility: HP-RTM is more flexible for complex integrated structures, reducing the number of subsequent assembly parts (light weighting and fewer assembly steps), but molds and processes are harder to modify quickly. SMC is better suited for high-volume production with minimal design variations.

Safety and Operational Risks: HP-RTM resin injection and curing systems may involve low-viscosity toxic or volatile components, requiring stricter control of the operating environment, ventilation, and personal protective equipment.

5. Summary

|

|

SMC |

HP-RTM |

|

Fiber Type |

Chopped Random Fibers |

Continuous Fibers (Orientable) |

|

Material Cost per Part |

Low |

High (due to carbon fiber/epoxy cost) |

|

Tool / Equipment Complexity |

Middle (Press+heating) |

High (Requires injection metering, sealed molds, heating, and vacuum) |

|

Cycle Time / Production Capacity |

Suitable for high-volume production |

Production Capacity depends on resin curing; can be increased through parallel processing. |

|

Surface Quality |

Excellent (easy to achieve a smooth, attractive surface) |

Requires additional processing or film technology |

|

Structural Strength / Light weighting |

Middle |

High (especially when using carbon fiber) |

|

Flame Retardant / Weather Resistant |

Easily Achievable via Formulation |

Requires specialized formulation, with high cost |

|

Applicable Components |

Aesthetic covers, lids, and high-volume parts |

Load-bearing housings, reinforcements, and complex integrated structures |

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский