PCM (Prepreg Compression Molding) is an advanced composite manufacturing technology that uses prepreg materials for compression molding. PCM composites offer advantages such as lightweight structure, high strength, corrosion resistance, and exceptional stability.

This process is widely used in new energy vehicles, energy storage systems, and various industrial equipment, and has become a key development direction for next-generation high-performance materials.

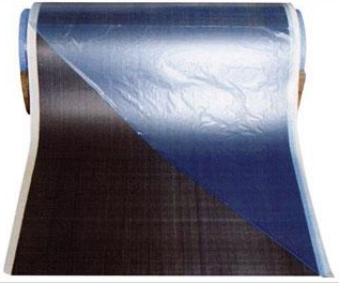

1. Raw Materials

The fast-curing thermoset prepreg technology—developed specifically for automotive components such as battery pack upper covers—has become highly mature and fully meets the needs of rapid-cycle compression molding production.

- Features of the Prepreg Material:

Curing time: 4–5 minutes

Production cycle: 6–10 minutes per part

Flame retardant grade: UL 94 V-0 (2017)

Complies with RoHS certification

- Differences Between PCM, SMC, and LFT-D:

Reinforcement:

PCM uses continuous woven glass fabrics, while SMC and LFT-D use chopped fibers.

Matrix Resin:

PCM is based on epoxy resin, offering good performance compared with unsaturated polyester resin (SMC) and PP resin (LFT-D).

Material Flow Behavior During Molding:

In PCM molding, fibers do not flow; only a small amount of resin flows locally around the material.

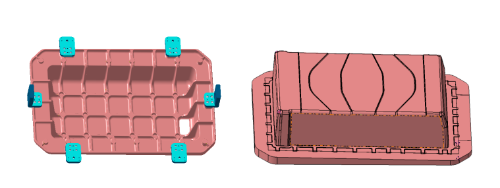

2. Mold

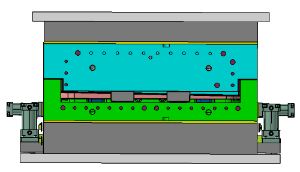

When the PCM compression molding process enters standardized mass production, steel mold manufacturing technologybecomes essential. The mold core material is typically P20 steel, which ensures long-term durability and stable performance.

- Features of Steel Molds:

High strength and long service life (≥100,000 parts), suitable for mass production

Higher cost, with two structural options: transfer mold or closed mold

Long manufacturing cycle, requiring approximately 60 days

Daily output: 80–120 sets (paired molds) per mold set

- Main mold

- Transfer Mold

- Mold after assembling

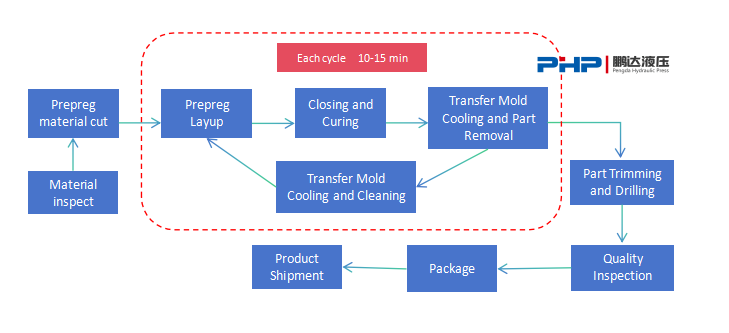

Mold Utilization Scheme: One Main Mold + Four Transfer Molds

Use Fibersim software to generate the ply development drawing, enabling precise cutting of the prepreg materials.

Operate 4–5 transfer molds in rotation, achieving a production cycle of 10–15 minutes.

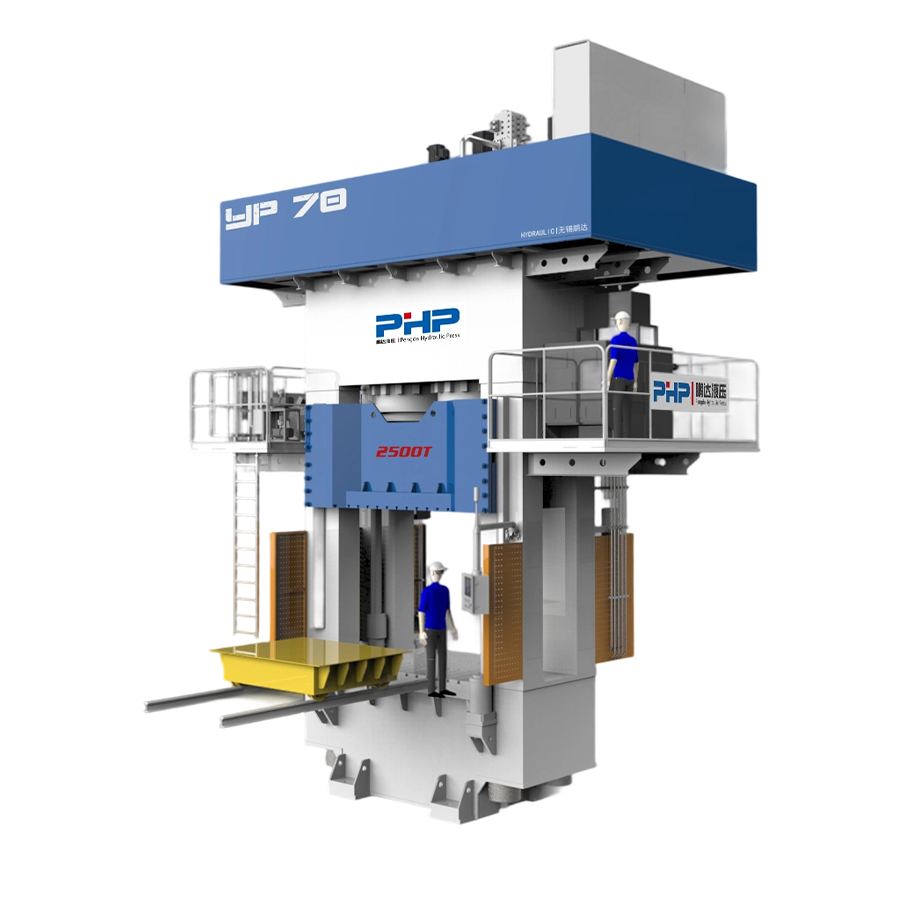

3. PCM Compression Molding Press

The PCM servo compression molding press is a high-precision composite forming machine driven by a servo motor. Its working principle involves placing the pre-formed prepreg material into a heated mold. The PCM press then rapidly closes the mold, builds pressure, enables fast curing of the prepreg, and finally opens the mold for part removal. It is a specialized hydraulic system designed for efficient and stable composite molding.

- Advantages of Pengda’s PCM Servo Compression Molding Press:

Robust frame structure ensures good overall machine rigidity

Servo-driven system significantly reduces energy consumption

Smooth operation with zero vibration for high-precision molding

Integrated piping system effectively minimizes oil leakage risk

Optional integrated heating system for flexible customer configuration

Optional two-level platform design for efficient use of floor space

- Heating Control System

When providing PCM compression presses, PHP PRESS offers an optional oil-based mold heating control system. The mold temperature controller (MTC) can be placed on the press's second-level platform, effectively saving ground space.

Oil outlet lines are connected using rigid pipes, while the connection to the mold uses flexible hoses.

Heating hoses on the slide are housed inside a steel drag chain for good protection.

All heating pipelines are wrapped with thermal insulation to prevent high-temperature injury to operators.

Quick-connect heating couplings are reserved on both the slide and the bolster, enabling fast connection between the mold and the MTC.

- Integrated Production Line Solution

Automatic Cutting Machine:

Enables fast and precise cutting of prepreg materials, ensuring consistent production cycle times.

Transfer Robots / Preforming System:

Multiple transfer molds are transported and positioned rapidly and accurately under high-temperature conditions.

Compression Press & Mold Temperature Controller:

Integrated with downstream equipment to achieve stable and efficient PCM molding.

Laser Trimming and Drilling Machine:

Provides precise cutting of the 20 mm process allowance on continuous-fiber prepreg parts.

Automatic cutting machine Transport robotic arm PCM press+ oil heater Laser trimming and drilling

4. Performance Comparison: PCM, LFT-D, and SMC

Comparison of Battery Pack Upper Cover Performance Across the Three Processes

|

Performance |

PCM |

LFT-D |

SMC |

|

Density g/cm3 |

1.95-2.0 |

1.2 |

1.85 |

|

Product Thickness mm |

0.9-1.5 |

3-3.5 |

2.5-3 |

|

Average Areal Weight g/m2 |

1.67-2.28 |

3.6-4.2 |

4.63-5.55 |

|

Tensile Strength MPa |

400 |

60-80 |

80-120 |

|

Flexural Strength MPa |

600 |

90-110 |

80-120 |

|

Resin Uniformity |

Uniform |

Resin-rich edges |

Resin-rich edges |

|

Surface Quality |

Smooth |

Fiber floating |

flow marks on surface |

- Advantages of PCM Battery Pack Upper Covers

Thickness reduction ≥ 52%

Weight reduction ≥ 36%

Tensile load capacity improved by ≥ 20%

Flexural load capacity improved by ≥ 33%

Minimal resin flow, ensuring uniform resin distribution

No surface fiber floating or flow marks

The PCM Servo Compression Molding Press from PHP (PENGDA Hydraulic Press) integrates high efficiency, energy savings, high-precision control, and outstanding reliability, providing advanced solutions for high-end composite material molding. Powered by a full-servo drive system, it significantly reduces energy consumption, while its innovative structural design—built to strict European manufacturing standards—ensures exceptional operational stability space utilization.

The equipment is particularly well-suited for the fast-cycle molding of PCM battery pack upper covers used in new-energy vehicles. Beyond that, it has been widely applied in automotive, aerospace, rail transit, and urban infrastructure, offering strong technical support to help enterprises across multiple industries. It stands as an ideal choice for driving industrial upgrading and promoting lightweight development.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский