To choose the appropriate SMC press tonnage, it is necessary to first clarify the molding pressure of SMC products, and then based on this, select the appropriate SMC press tonnage according to the usage specifications of hydraulic presses.

1. What is the molding pressure of SMC products?

The forming pressure of SMC (Sheet Molding Compound) products is essentially the pressure required to place the SMC mold into the SMC hydraulic press, maintain the mold closed, and heat, flow, fill, and compact the SMC sheet in the mold cavity, ultimately forming the product.

2. How to quickly calculate the forming pressure of SMC products?

Quick calculation formula for SMC product forming pressure:

F = P × S

Note:

① F: Pressure required for SMC product compression molding (ton)

② P: Molding pressure per unit area of SMC product (ton)

Due to different material ratios, the molding pressure of different SMC products varies, usually ranging from 600 to 1200 tons per square meter. Generally speaking, the greater the pressure, the better the surface quality of the final product.

③ S: Projection area of SMC products (m ²)

The projected area of the final product, including the core occupancy and channel/channel projection, and deducting the open hole area without material in the product. Due to the need to consider an appropriate safety factor when selecting the tonnage of SMC press, the opening area can be ignored when quickly calculating the projected area of the product, except for large-area openings.

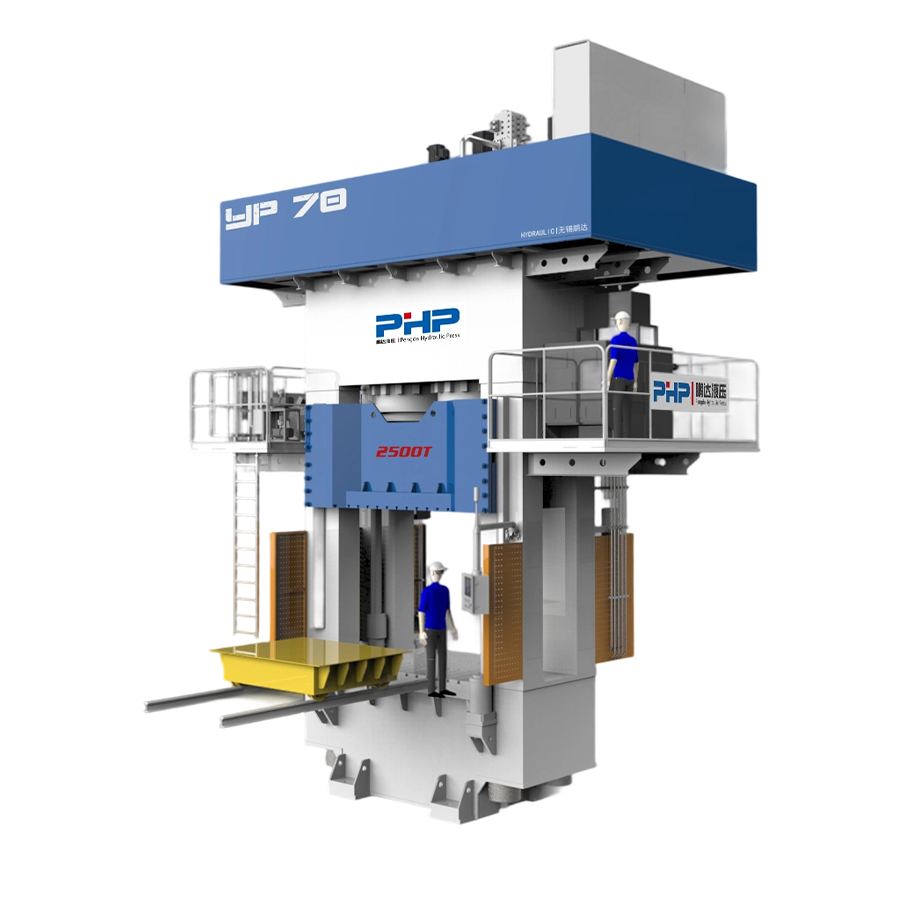

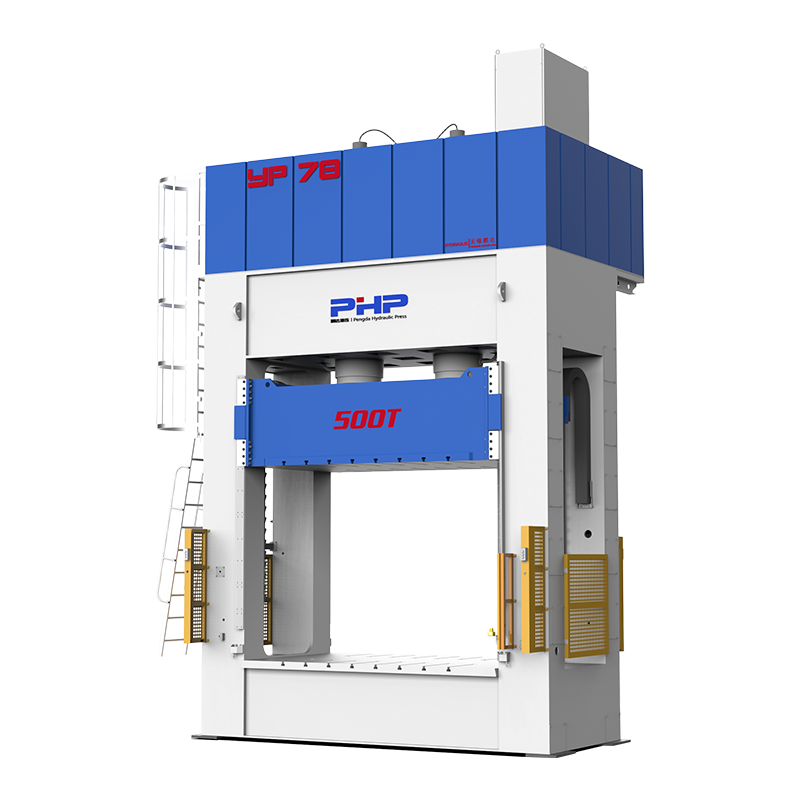

3. Tonnage selection of SMC press

By calculating the product pressure, the correct tonnage of the hydraulic press can be inferred based on its usage specifications.

Typically, a hydraulic press can maintain a stable pressure range of 20% to 80% of its full tonnage for long-term use. Therefore, when calculating the forming pressure of the product, a margin of about 20% should be allowed when choosing a hydraulic press, and industry standard parameters should be selected as much as possible. For example, when the calculated forming pressure is 800 tons, a hydraulic press of 1000 tons is more suitable.

4. Complete calculation steps

① Measure or draw the projected area S (m ²) of the part in the direction of the mold opening. Attention: If the part has multiple parting surfaces or multiple cavity molds, it should be calculated based on the total projected area (sum of each cavity).

② Selecting or estimating the forming pressure p (ton or Pa or MPa): It can generally be obtained from material suppliers, process manuals, or similar workpiece experience. The molding pressure of SMC is greatly affected by the formula, preheating temperature, thickness, fiber content, and flow characteristics.

③ Substitute the formula to obtain the forming pressure (in tons or N).

④ Add a safety factor (usually ranging from 1.1 to 1.3, depending on uncertainty and mold structure) to obtain the design resultant force.

⑤ Divide the resultant force by 9806.65 to obtain the required compressor tonnage (t).

⑥ When selecting a press machine, it is also necessary to consider the maximum opening height of the mold, stroke, heating/cooling requirements, holding time, and oil circuit response.

5. Precautions

① The definition of projection area: using the maximum projection area of the part on the parting surface (including the area of the flow channel and the area that will produce flash edges), the blank area should be deducted for hollow or large opening parts. But when calculating quickly, the opening area can be ignored.

② The choice of molding pressure: the larger the better; Excessive height can cause mold damage, excessive flashing, surface defects, or excessive material flow. It should be based on the ability to fill and achieve the target thickness/density.

③ The influence of materials and temperature on pressure: The viscosity and tensile resistance of materials vary greatly at different temperatures, and preheating temperature, mold temperature, and fiber/filler content can significantly change the required pressure.

④ Safety margin: In actual selection, a margin of 10% to 30% is often added to cover factors such as process fluctuations and mold friction.

⑤ Unit conversion: Mixed units such as psi, bar, kgf/cm ², ton, etc. are commonly used on engineering sites. When calculating, it is necessary to convert them to the same system to avoid errors.

6. Common forming pressure range in the industry (for reference)

| Industry | Parts | Reference tonnage |

| Electrical industry | Transformer casing, electrical box, etc | 600~700 tons |

| Urban construction | Manhole cover, water tank panel, garbage bin, grille panel, etc | 600~700 tons |

| Rrail transit | Truck components, track doors and windows, etc | 800~1000 tons |

| New energy vehicle | Battery case, energy storage box, etc | 800~1000 tons |

| Passenger car | High end car components | 1000~1200 tons |

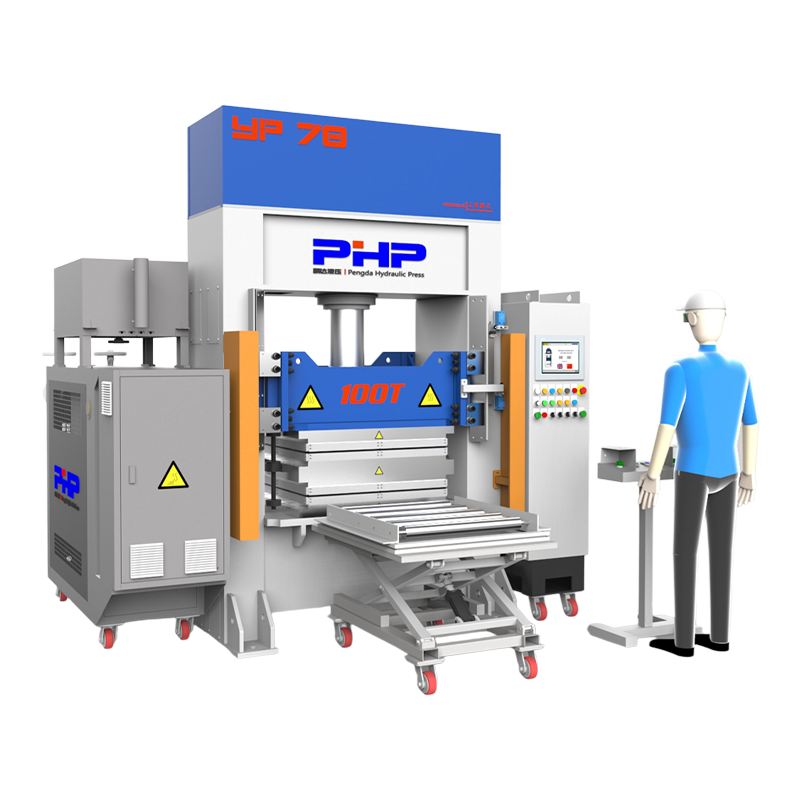

7. Example Calculation

Assumption: The projected area of the part is 5000 cm ², and the average forming pressure determined by the process is 5Mpa. (Note: This is an example value, the actual material and process will be determined). Then:

P=5*106Pa

S=5000/10000=0.5m2

F=P*S=5*106*0.5=2.5*106 N

F=2.5*106 N/9806.65 ≈255吨

Because:

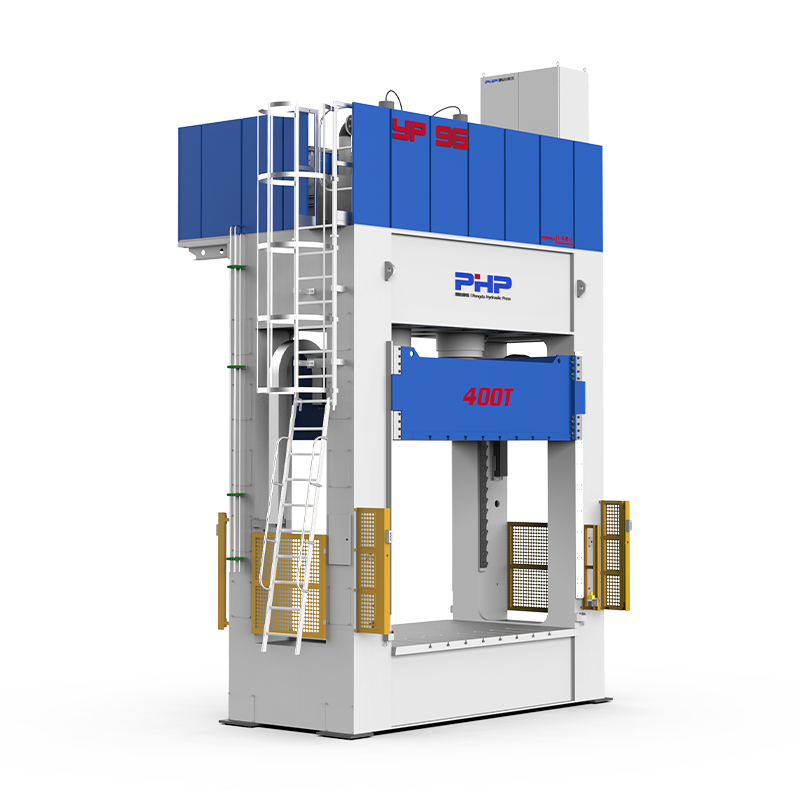

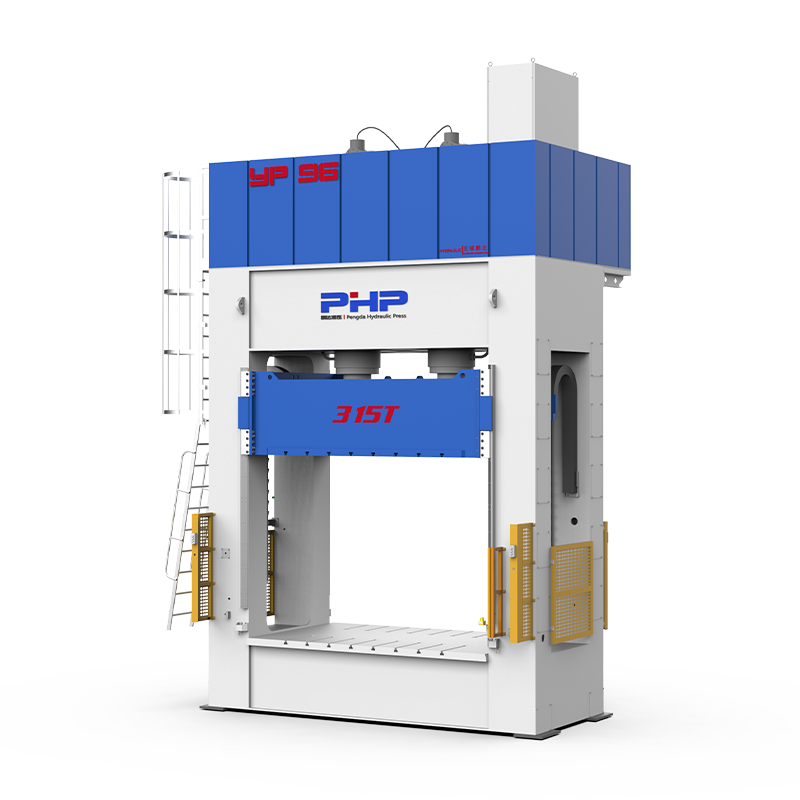

255/315≈81%

255/400≈64%

Therefore, when choosing SMC press, a 400 ton press is the most suitable.