In modern manufacturing, with the continuous advancement of production processes and the constant updating of equipment technology, automatic trimming technology has gradually become an important part of various production lines. Whether in precision manufacturing or mass production, automatic trimming plays a crucial role. Especially in the processing of materials such as plastics, rubber, and metals, auto trim parts presses can significantly improve product yield, reduce production costs, and enhance overall production efficiency. Therefore, more and more companies are beginning to value this technology and are gradually introducing automated equipment.

Content

Overview of Automatic Trimming Technology

Automatic trimming technology is a technique that uses automated equipment to trim excess parts or burrs generated during the production process. This technology is typically applied in processes such as mold forming, stamping, and injection molding, and plays an irreplaceable role, especially in the production of products requiring high precision. Automatic trimming not only ensures a clean product appearance but also improves product precision, avoiding errors that may occur during manual trimming.

In traditional production models, trimming is usually done manually. While manual trimming can meet requirements to some extent, the unavoidable errors of manual operation and high labor intensity often make it unsuitable for large-scale production. Automatic trimming systems, however, effectively replace manual trimming through highly precise control systems and automated trimming tools, improving production efficiency and trimming accuracy.

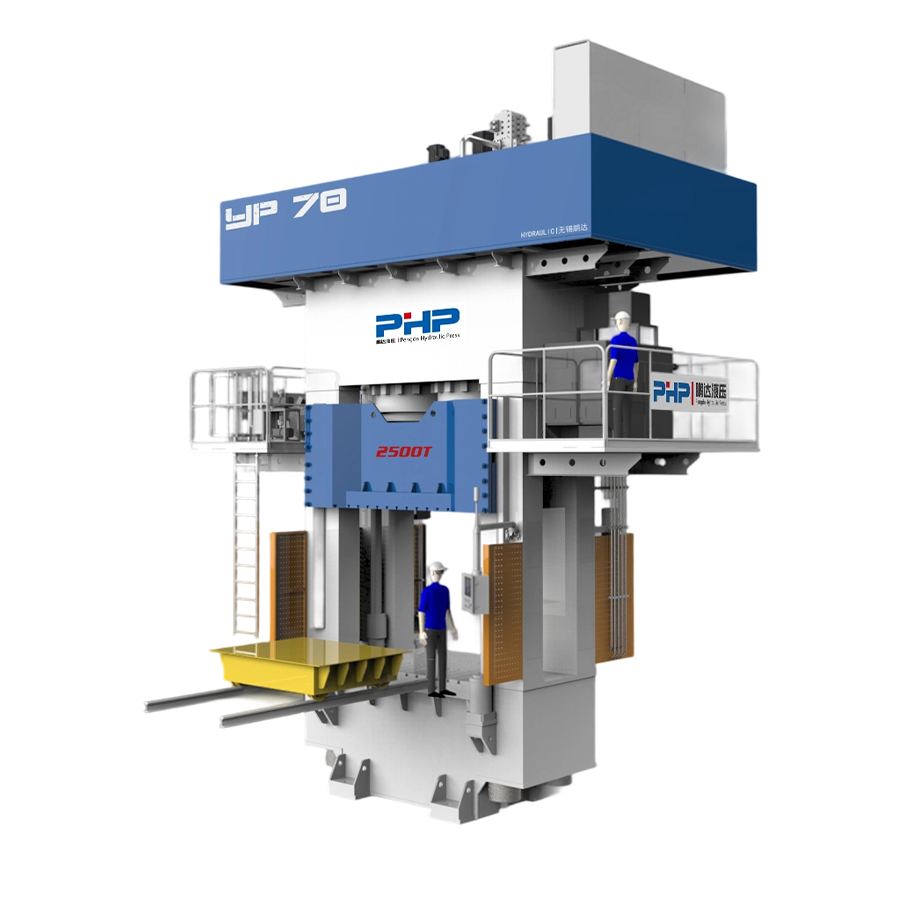

Working Principle of Auto Trim Parts Press

The working principle of automatic trimming equipment usually includes several key steps: raw material feeding, automatic adjustment of trimming tools, precise calculation by the control system, and final waste removal. The equipment monitors the processing status in real time through advanced sensors and control systems, automatically adjusting the position and force of the trimming tools according to production requirements, thus ensuring the trimming accuracy of each product.

The equipment is usually equipped with high-precision sensors and vision systems, which can perform real-time detection of irregularly shaped workpieces to ensure trimming accuracy. At the same time, the adjustment of the trimming tools can also be automated according to the different needs of the product, greatly reducing manual intervention and improving the automation level of the production line.

Advantages of Automatic Trimming Technology

1. Increased Production Efficiency

One of the major advantages of automatic trimming technology is its ability to significantly increase production efficiency. Due to the fast and efficient processing capabilities of automatic trimming equipment, it can complete more production tasks in a shorter time compared to manual trimming. Especially for products requiring mass production, automatic trimming systems can maintain a continuous and stable working state, avoiding problems such as fatigue that may occur in manual operation.

2. Ensuring Trimming Accuracy

In precision manufacturing processes, the trimming accuracy of a product directly affects the quality and performance of the final product. Automatic trimming technology utilizes high-precision control systems and tool adjustment techniques to perform precise trimming, not only reducing human error but also ensuring consistency in the trimming process for each product. This is especially important for industries requiring high precision.

3. Reducing Production Costs

Although the initial investment in automatic trimming equipment is relatively high, in the long run, it can effectively reduce production costs. First, automatic trimming reduces labor costs and avoids rework costs caused by manual operation errors. Secondly, due to its efficient trimming speed and accuracy, automatic trimming can improve the yield rate and reduce the scrap rate, thereby reducing material waste.

4. Improving the Working Environment

Traditional manual trimming often requires operators to work in a high-intensity labor environment for extended periods, which not only easily leads to fatigue but also increases the risk of occupational diseases. With the adoption of automatic trimming systems, production line workers can reduce the time spent on manual operations, reducing physical strain and improving employee safety and health.

Application Fields of Automatic Trimming Technology

Automatic trimming technology is widely used in various industries, especially in the following areas:

Plastic and Rubber Product Manufacturing

In the production of plastic and rubber products, automatic trimming technology is mainly used to remove excess material generated during injection molding, extrusion, and other processes, ensuring a smooth and burr-free product appearance. Because the surface of plastic and rubber products often requires a very smooth and flat finish, automatic trimming technology can meet this requirement through precise control systems.

Metal Processing and Stamping

In metal processing and stamping, trimming is also an essential step. Especially when processing large quantities of stamped products, automatic trimming can quickly remove burrs and excess material from the metal surface, avoiding errors in manual trimming and improving the appearance and accuracy of the product.

Electronic Component Manufacturing

In the production of electronic components, automatic trimming technology is widely used for trimming circuit boards, housings, and other components. Electronic components typically have strict requirements for size and appearance. Automatic trimming technology not only improves trimming accuracy but also reduces electronic failures caused by improper trimming.

Frequently Asked Questions (FAQ)

What maintenance does automatic trimming equipment require?

Automatic trimming equipment usually requires regular inspection and cleaning, especially the trimming blades, which need to be replaced or sharpened regularly to ensure trimming accuracy. The equipment's sensors and control system also need regular calibration to ensure stable operation.

Is the automatic trimming system suitable for all production types?

While automatic trimming systems are applicable to most production types, for products with special shapes or extremely high precision requirements, customized adjustments may be needed depending on the specific situation.

Can automatic trimming technology improve the smoothness of the trimmed surface?

Automatic trimming technology can be finely adjusted according to the specific needs of the product, thereby improving the smoothness of the trimmed surface and ensuring that the product meets high-quality appearance standards.

Does the automatic trimming system save space?

Modern automatic trimming equipment is designed to be increasingly compact, and many devices can be integrated into the production line, occupying relatively little space and not affecting the overall layout of the production line.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский