Bring non-metallic hydraulic presses to the world.

PHP(Pengda Hydraulic Press)

-

24

Years Industry Experience

-

60+

Number Of Patents

-

20+

Sales Countries And Regions

PHP(Pengda Hydraulic Press) founded in 2004, is a professional manufacturer of non-metallic hydraulic presses committed to green industry principles and technological innovation.

PHP(Pengda Hydraulic Press) specializes in designing and developing energy-saving hydraulic presses through continuous innovation. We provide advanced industry solutions to domestic and international customers across diverse sectors.

Our R&D focuses on two categories of non-metallic molding presses:

-

Servo Composite Hydraulic Presses: Designed for molding processes including SMC, LFT-D, GMT, HP-RTM, STM, and carbon fiber high-temperature applications. These serve industries such as new energy vehicles, aerospace, rail transit, urban construction, low-voltage electrical appliances, and military products.

-

Servo Interior Parts Hydraulic Presses: Used for automotive interior processes like molding, compounding, punching, and heating. Applications include overhead liners, carpets, luggage compartments, seats, soundproof components, and wheelhouses.

Key equipment features include energy efficiency, space optimization, operational stability, safety, reliability, and advanced manufacturing standards.

PHP(Pengda Hydraulic Press) is dedicated to manufacturing stable and reliable non-metallic presses that address industry challenges while delivering comprehensive solutions. Our fully automated production lines provide integrated services, earning strong customer recognition.

For nearly two decades, PHP(Pengda Hydraulic Press) has maintained its specialization philosophy within this niche sector. Focusing on mechanical design excellence, standardized key systems, and responsive global service, we consistently prioritize customer perspectives to meet evolving needs, foster mutual growth, and cultivate long-term partnerships.

Enterprise Philosophy

-

Enterprise Mission

Innovate for customers’ benefits. -

Corporate Vision

Let every worker be the master of the factory. -

Enterprise Policy

Confidence, Integrity, Diligently, Creative. -

Business Goal

Build a century old PHP(Pengda Hydraulic Press) brand for the world.

Advanced Manufacturing

Quality forms the foundation of our enterprise. Advanced processing and inspection equipment enable us to consistently deliver high-quality products. Our digital workshops integrate Mazak and DMG Mori CNC systems with industrial robotics, enabling highly automated operations with minimal manual intervention and flexible manufacturing capabilities. These are supported by integrated production management systems, including ERP, MES, and PLM platforms.

History

-

2001

Mr. Sun Tie founded Wuxi Pengda Hydraulic Machine Tool Factory in Wuxi. In its initial phase, the company operated from a small workshop with a team of approximately 4-5 people, focusing on producing small hydraulic presses under 100 tons, such as C-frame and four-column hydraulic presses.

-

2005

The company relocated to a new factory building, and its team grew to nearly 20 employees.

-

2009

Pengda took a strategic step towards internationalization by initiating export operations. Concurrently, it successfully introduced advanced servo drive system technology to the market.

-

2011

Pengda acquired 25,000 square meters of land for constructing a new factory facility. That same year, the company secured independent export qualification, strengthening its capabilities for competing in international markets.

-

2014

The Pengda team made a key strategic decision to concentrate on two specialized segments: "Servo Composite Material Hydraulic Presses" and "Servo Interior Parts Hydraulic Presses," deepening its focus within these niche markets.

-

2018

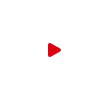

To meet evolving business demands, Wuxi PengdaHZ Intelligent Equipment Co., Ltd. was established, specializing in the research, development, and manufacturing of "Servo Composite Material Hydraulic Presses."

-

2022

The company expanded its factory area. The number of assembly workshops increased to three, leading to a noticeable improvement in production capacity and delivery efficiency.

English

English 中文简体

中文简体 Español

Español Português

Português Deutsch

Deutsch русский

русский